- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LUYE

-

Dimension(L*W*H):

-

Depends on model

-

Weight:

-

500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Video technical support, Field installation, commissioning and training, Field maintenance and repair service

-

Certification:

-

CE ISO BV

Quick Details

-

Application:

-

Food, Beverage

-

Packaging Type:

-

Cartons

-

Packaging Material:

-

Wood

-

Voltage:

-

380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LUYE

-

Dimension(L*W*H):

-

Depends on model

-

Weight:

-

500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Video technical support, Field installation, commissioning and training, Field maintenance and repair service

-

Certification:

-

CE ISO BV

Product Description

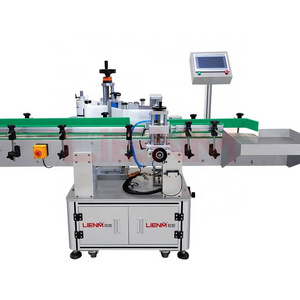

LUYE series Automatic Bopp Hot

Melt Glue Labeling Machine

Brief Introduction

All-cover type stainless steel host machine: the whole machine is waterproof as well as rustless.

Adjustable cutter head: uniquely cyclotron cut-off, double sided cutting edge with a long service life.

Single positioning centre guide pillar: a more stable for label delivery.

Synchronous bottle divider: a more stable transmission for bottle.

Bottom set of label brush:a more precision for casting label.

Label-controlling electric-eye shelf:unique combination of tail and electric-eye to improve the precision for cutting off the membrane materials.

Push-button control cabinet: a more humanized operation.

Independent feeding material shelf: the position of the material shelf is optional at will.

Electrical Appliance Configuration Specification: It adopts PLC programmable controller,imported servo motor,servo driver,frequency converter and transducer; besides,it dopts The positioning module to ensure the casting label precise, rapid and stable.

Applicable Bottle Types: Various kinds of bottle types, for example: round bottle, square bottle, flat bottle, curved bottle and cup-shaped, etc.

Adjustable cutter head: uniquely cyclotron cut-off, double sided cutting edge with a long service life.

Single positioning centre guide pillar: a more stable for label delivery.

Synchronous bottle divider: a more stable transmission for bottle.

Bottom set of label brush:a more precision for casting label.

Label-controlling electric-eye shelf:unique combination of tail and electric-eye to improve the precision for cutting off the membrane materials.

Push-button control cabinet: a more humanized operation.

Independent feeding material shelf: the position of the material shelf is optional at will.

Electrical Appliance Configuration Specification: It adopts PLC programmable controller,imported servo motor,servo driver,frequency converter and transducer; besides,it dopts The positioning module to ensure the casting label precise, rapid and stable.

Applicable Bottle Types: Various kinds of bottle types, for example: round bottle, square bottle, flat bottle, curved bottle and cup-shaped, etc.

|

Name

|

Opp Hot Melt Round Bottle Labeling Machine

|

|

Power supply

|

Three-phase 380V 50HZ 8000W

|

|

Machine dimensions

|

3000mm×2500mm(can be adjusted by customer requirements)

|

|

Method of speed adjustment

|

8000 BPH 500 bottle and 750 ml bottle

|

|

Max speed of labels feed

|

maximum speed of 100 meters labels / min

|

|

Labeling precision

|

±1mm

|

|

Maximum label width

|

200mm(standard width, can be adjusted )

|

|

The maximum outer diameter of label

|

600mm

|

|

Paper core Hot melt

|

152 mm

|

|

Labeling glue

|

glue at both ends of each label with hot melt

|

|

Gluing temperature

|

120~160℃

|

|

Labeling type for products

|

suitable for round or square containers made of plastic, metal, glass

|

|

Type of label

|

BOPP,opp label,paper-plastic composite film label ,paper label

|

|

Labeling stations

|

(8per cycle )

|

|

Machine weight

|

about 3000 kg

|

Feature

1).The adjustment of label cutting blade is easy and simple.

2).Vacuum-grip cylinder is made of high hardness material, the additional old handler can reduce the frictions of labels and prevent static electricity.

3).The change-over of shape pars can be finished within 10 minutes;

4).The position of cutting blade can be quickly and accurately adjusted by manual control cabinet;

5).Vacuum-grip cylinder and cutting unit adopt special material which are wear proof and heat protection;

6).The self-adjustment knob can reset the I-MARK position while change he cutting length of labels;

2).Vacuum-grip cylinder is made of high hardness material, the additional old handler can reduce the frictions of labels and prevent static electricity.

3).The change-over of shape pars can be finished within 10 minutes;

4).The position of cutting blade can be quickly and accurately adjusted by manual control cabinet;

5).Vacuum-grip cylinder and cutting unit adopt special material which are wear proof and heat protection;

6).The self-adjustment knob can reset the I-MARK position while change he cutting length of labels;

Certifications

Our Factory

FAQ

Related Products

Hot Searches