- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/220V 50-60Hz

-

Place of Origin:

-

Zhejiang, China

-

Year:

-

2022

-

Brand Name:

-

LTPM CHINA

-

Dimension(L*W*H):

-

L1230*W850*H1800mm

-

Weight (KG):

-

500

-

Number of injection needles:

-

1 needle

-

Compressed Air:

-

0.55-0.75Mpa 15L/S

-

Total Power:

-

3 KW

-

Applicable Syringe Specifications:

-

0.5-80ml

-

Applicable Materials:

-

Liquid and ointment

-

Filling Accuracy:

-

≤±1-2%

Quick Details

-

Production Capacity:

-

1800-2700

-

Automatic Grade:

-

Automatic

-

Driven Type:

-

Electric

-

Voltage:

-

380V/220V 50-60Hz

-

Place of Origin:

-

Zhejiang, China

-

Year:

-

2022

-

Brand Name:

-

LTPM CHINA

-

Dimension(L*W*H):

-

L1230*W850*H1800mm

-

Weight (KG):

-

500

-

Number of injection needles:

-

1 needle

-

Compressed Air:

-

0.55-0.75Mpa 15L/S

-

Total Power:

-

3 KW

-

Applicable Syringe Specifications:

-

0.5-80ml

-

Applicable Materials:

-

Liquid and ointment

-

Filling Accuracy:

-

≤±1-2%

Product Introduction

This product is specially designed by our company for the filling of plastic syringes. It is an automatic packaging equipment for aseptic and efficient filling of syringes. The equipment runs smoothly, is simple to operate, and is equipped with intelligent detection devices, with high automation, high work efficiency, convenient maintenance, and the technology can reach the current domestic industry advanced level.

Machine Data

|

Applicable materials

|

Liquid and ointment

|

|

Applicable syringe specifications

|

0.5-80ml

|

|

Filling accuracy

|

≤±1-2%

|

|

Number of injection needles

|

1 needle

|

|

Production capacity

|

2400-2700 p/h

|

|

Total power

|

3KW

|

|

Voltage

|

380V/220V 50-60Hz

|

|

Compressed air

|

0.55-0.75Mpa 15L/S

|

|

Dimensions

|

L1230×W850×H1800mm

|

|

Equipment weight

|

500KG

|

Main Feature

1.

This product is widely used for filling and capping of various types of plastic syringes, and special types can be customized.

2.

The surface is made of SUS 304 stainless steel, and the contact parts are made of SUS 316L stainless steel and medical silicon rubber, which fully meets the requirements of GMP specifications.

3.

The ceramic plunger pump realizes quantitative filling, is resistant to acid and alkali corrosion, wear-resisting and high temperature, and has high filling accuracy.

4.

The conveying and sorting of the caps is realized by the vibratory feeder, which adopts the SUS 316L stainless steel clean plate, which has a bright surface treatment and no clean dead corners.

5.

Adopting internationally well-known electrical components, implementing non-interference modular control, all synchronous actions are controlled by servo motors, which are accurate and reliable, and easy to operate.

6.

The operation of the motor is controlled by the PLC programming controller, and the human-computer interaction interface monitors and displays the working status of each station in real time, and automatically alarms and displays the fault location in real time, and the fault prompts.

7.

Fully automatic operation, automatic filling, automatic organizing and automatic capping.

8.

The method of filling the syringe head can eliminate the air inside the syringe to the greatest extent and improve the qualification rate.

9.

Modular design, easy to locate, easy to expand, can be used as a stand-alone machine or connected to hoist, assembly machine, rotary rod machine, labeling machine and other equipment to form a production line.

10.

Optional 100-level laminar flow hood to achieve high-demand clean production.

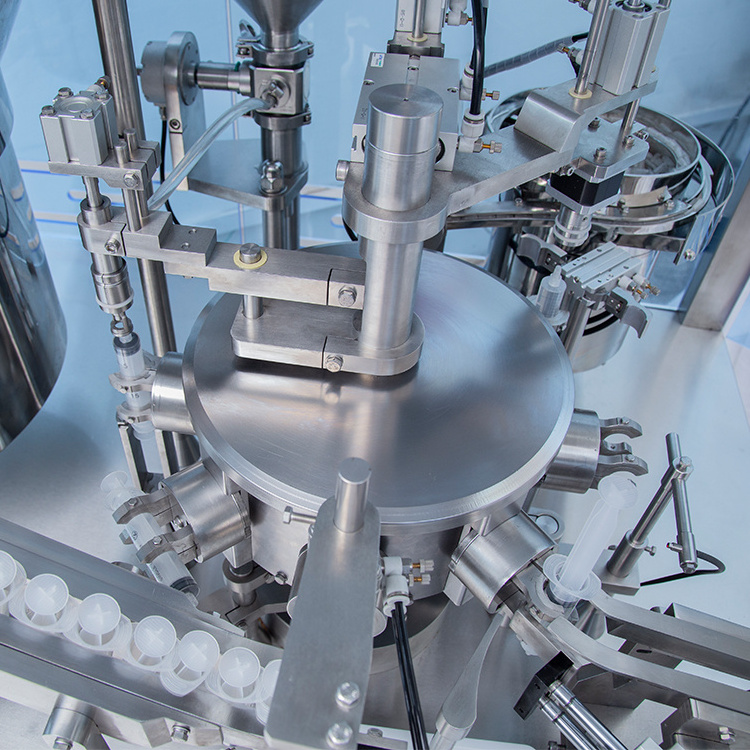

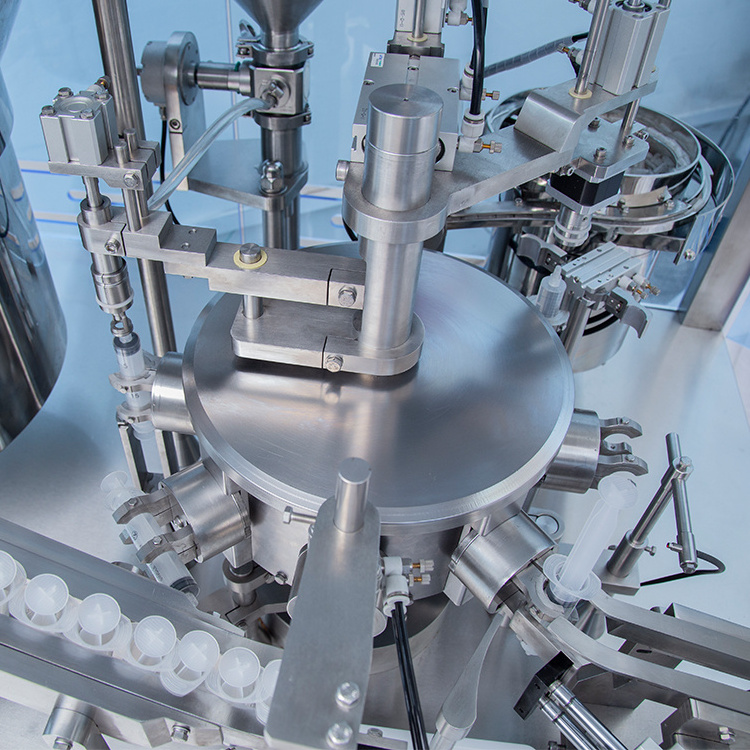

Details Images

Working Station

Included the syringe loading, filling, capping and Output finish product guider.

Syringe tube loading guider

Syringe sort of vibrating plate will sort of the syringe tubes and send to the loading guider one by one, loading guider will send

syringe tub into turn table.

syringe tub into turn table.

Filling Station

Automatic fill liquid intosyringe from top to bottom.

Arrange and Feeding Caps

Automatic Arranging thelids by vibrating disk(customby the dimension of your syringe).

Capping Station

Automatic capping the lid on syringe.

Output Station

Automatic output finish product.

Final Product

Company Introduction

Our Company

- LTPM CHINA is one of China's leading system suppliers for the pharmaceutical, beverage and food sectors.

- Our portfolio includes machinery and plants as well as advanced process technology, components and comprehensive services. Used across diverse industries, they enhance the sustainability and efficiency of production processes globally.

- Our business model has evolved significantly since our founding in 1996 as a Pharmaceutical Machinery Company. Our machinery manufacturing bases all have been in this field for more than 15years which can give our client more reliable service. Professional, Service, Genuineness, Enthusiasm are our value. LTPM CHINA exports pharmaceutical machinery to more than 30countries which includes European country and Americans. Through serving different pharmaceutical companies in different country, we believe in success would affect success.

- Our company mission is creating a professional platform for the industry and achieving individual value. LTPM CHINA, Your best pharmaceutical production solution!

Our Machinery Workshop

Our Certificates

ISO, CE, SGS, BV Certified Company.

Our Sales Team

Our Customers

Orders from Alibaba

Packing & Shipping

All machine delivery with anti rust spray, film wrapping and Sea shipping affordable wooden box.

FAQ

Q: What is the warranty period for your machine?

A: 5 years free warranty.

Q: Are you a real factory/manufacturer?

A: Of course. Our factory is inspected by third party. We much welcome you to visit us and free to pick you up form hotel. You don't have time? We can use live video and you can visit us on line.

Q: Is engineer available to serve oversea?

A: Yes, we can send engineers to your factory but all the fee will be on buyers. In order to save your cost, we will send you a video of full details machine installation and assist you till the end.

Q: How can we make sure about the machine quality after placing the order?

A: Before delivery, we will running half hour of the machine to checking the stability and sending you the testing video until you sastisfy. We will setting all the parameters well. And also you can arrange for quality checking by yourself or by your contacts in China.

Q: We are afraid you won't send us the machine after we send you the money?

A: We have our business license and certificate. And it is available for us to use alibaba trade assurance service, protect your money, machine qulaity and delivery are guaranted.

Q: Are you a real factory/manufacturer?

A: Of course. Our factory is inspected by third party. We much welcome you to visit us and free to pick you up form hotel. You don't have time? We can use live video and you can visit us on line.

Q: Is engineer available to serve oversea?

A: Yes, we can send engineers to your factory but all the fee will be on buyers. In order to save your cost, we will send you a video of full details machine installation and assist you till the end.

Q: How can we make sure about the machine quality after placing the order?

A: Before delivery, we will running half hour of the machine to checking the stability and sending you the testing video until you sastisfy. We will setting all the parameters well. And also you can arrange for quality checking by yourself or by your contacts in China.

Q: We are afraid you won't send us the machine after we send you the money?

A: We have our business license and certificate. And it is available for us to use alibaba trade assurance service, protect your money, machine qulaity and delivery are guaranted.

Hot Searches