- Product Details

- {{item.text}}

Quick Details

-

Product Name:

-

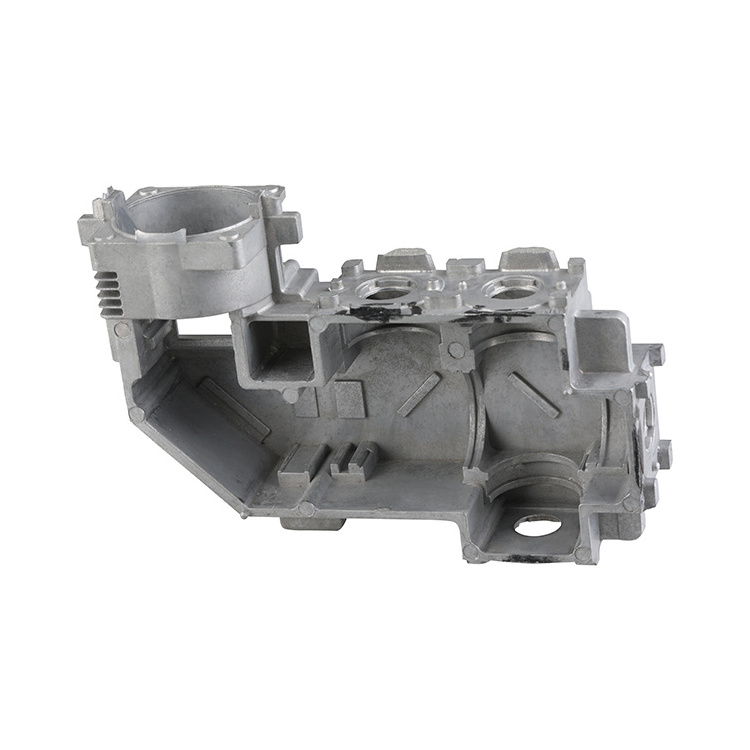

Custom Precise Aluminum Zinc Die Casting Parts

-

Product Material:

-

Zinc,Aluminum

-

Process:

-

Die casting,Machining

-

Secondary Machining:

-

Milling, Tapping,Grinding

-

Surface Treatment:

-

Painting And Powder Coating Or As Requirements

-

Other Surface Treatment:

-

Polishing,Spray Coating,Deburring,Grinding,Electroplating,Anodizing

-

Feature:

-

Anti-wear,Strong Abrasion Resistance ,Anti-friction Mold

-

Heat Treatment:

-

Anneal,Quenching,Tempering

-

MOQ:

-

1 Pcs

-

Certification:

-

ISO 9001

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

OEM

-

Model Number:

-

TF01

-

Product Name:

-

Custom Precise Aluminum Zinc Die Casting Parts

-

Product Material:

-

Zinc,Aluminum

-

Process:

-

Die casting,Machining

-

Secondary Machining:

-

Milling, Tapping,Grinding

-

Surface Treatment:

-

Painting And Powder Coating Or As Requirements

-

Other Surface Treatment:

-

Polishing,Spray Coating,Deburring,Grinding,Electroplating,Anodizing

-

Feature:

-

Anti-wear,Strong Abrasion Resistance ,Anti-friction Mold

-

Heat Treatment:

-

Anneal,Quenching,Tempering

-

MOQ:

-

1 Pcs

-

Certification:

-

ISO 9001

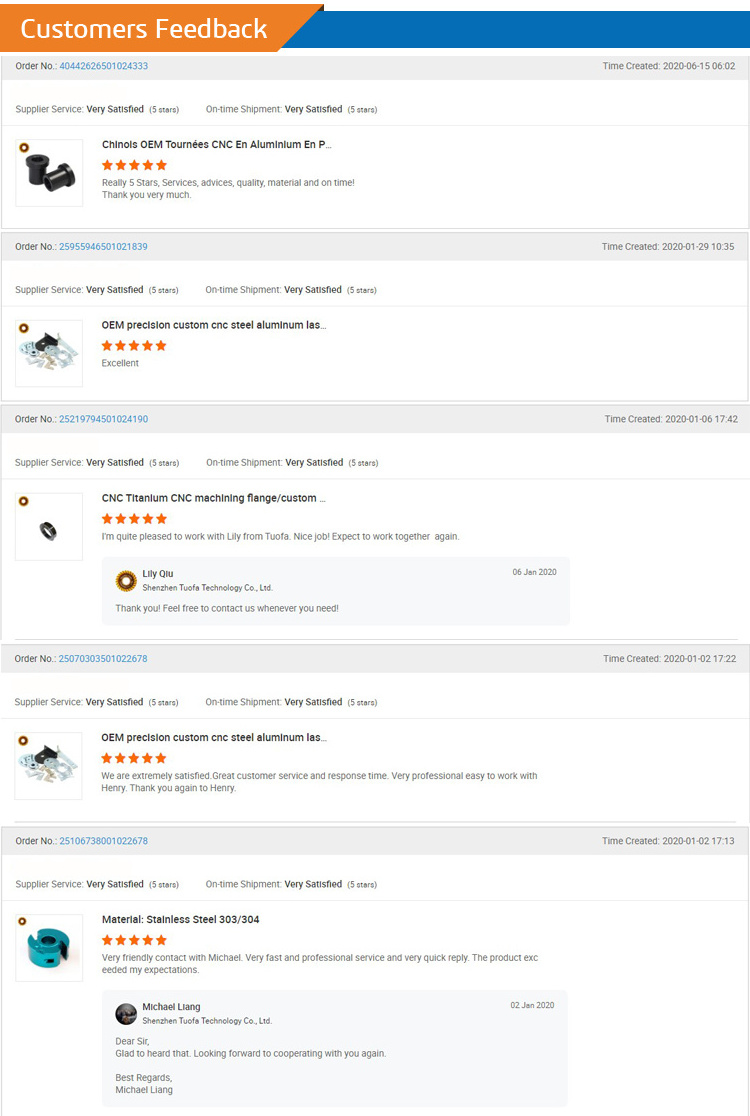

Customers Feedback

Product Parameters

|

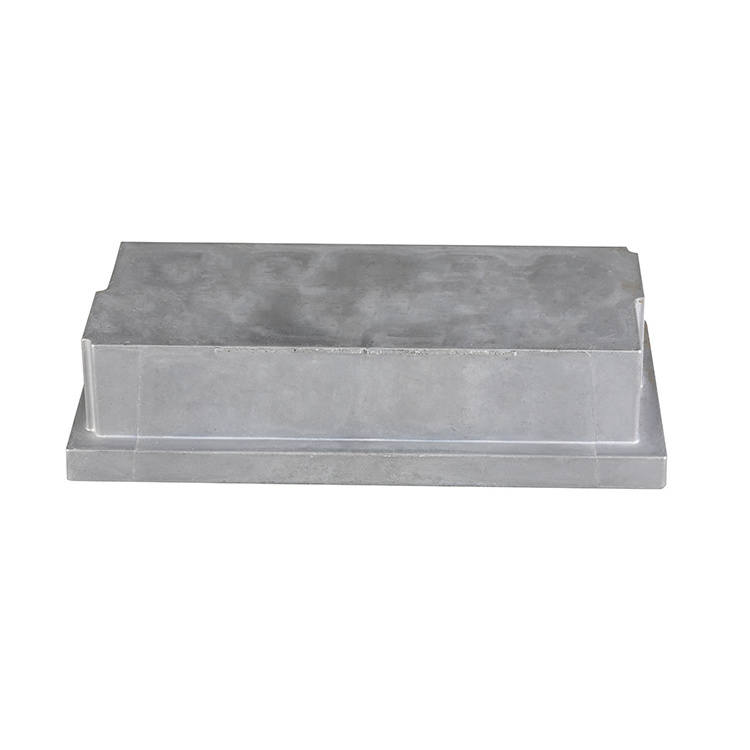

Mold Materials

|

Aluminum,45#, P20, H13, 718, 1.2344, 1.2738 And So On.

|

|

Materials

|

Aluminum Alloy ADC12 ,A380 Or Customized.

|

|

Film Standard

|

Powder Coating: 60-120 μ , Electrophoresis Film: 12-25 μ.

|

|

Part Weight

|

From 3g --- 20kg.

|

|

Surface Treatment

|

Mill-Finished, Powder Coating, Polishing, Brushing, Etc.

|

|

Drawing Format

|

IGES, STEP, Auto CAD, Solidworks, STL, PTC Creo, DWG, PDF, Etc.

|

|

Deep Processing

|

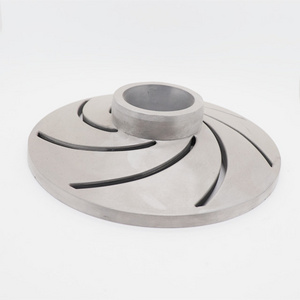

CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling.

|

|

Application

|

Industrial, Consumer, Food Processing, Aviation, Seals/Gaskets, Lighting, Packaging, Filter, Healthcare, Telecommunications,

Mechanical, Water Treatment, Appliance, Recreation, Lawn And Garden, Educational, Oil And Gas, Government, Construction, Plumbing, Surveillance, Pumps,Marine,Motors,Gears, RFID Tags, Electronics, And Fasteners. |

|

Materials

|

Aluminum Alloy: ADC12, ADC10, A360, A380, A356, 6061, 6063

Magnesium Alloy: AZ91D, AM60B Zinc Alloy: ZA3#,ZA5#,ZA8# |

|

Processing Craft

|

Drawings→ Mould Making → Casting →Rough Machining → CNC Machining→Surface Treatment →Product Checking→ Packing →Delivery

|

|

Tolerance

|

± 0.02mm

|

|

Surface Treatment

|

Electroplating, Chrome Plating, Zinc Plating, Nickel Plating, Electrophoresis, Anodization, Polishing, Sandblasting, Passivation,

Powder Coating, Spray painting, Etc. |

|

Quality Assurance

|

ISO9001:2020 Certified. Third Party Testing.

|

|

Mainly Testing Facility

|

Three-Dimensional Measuring Instrument (CMM), Salt Spray Test Box, Dynamic Balance Detector, Pneumatic Detection.

|

|

Features & Advantage

|

1.High Machining Accuracy. The Flatness Within 0.1mm.

2.High Strength And Not Easy To Deform. Has Good Electrical And Thermal Conductivity. 3.High Finish Appearance. Smooth Surface Roughness Is Ra1.6 after Machining. 4.Smooth Appearance. Corrosion Resistance. 5.Pass Salt Spray Test With 144 Hours. |

|

Standard

|

1.Aluminum alloy: ISO3522-84, ASTMB85-96, JISH5302:2000, EN1706:1998

2.Magnesium alloy: ISO/DIS16220-1999, ASTMB93/B93M-98, EN1754-1997 3.Zinc alloy: ISO301-1981,ASTMB327-98, JISH2021:1999, EN12844:1998 |

|

Application

|

3C Industry, Lighting Decoration, Electrical Appliances, Auto Parts, Furniture Parts, Electric Tool, Medical Equipment,

Intelligent Automation Equipment, Other Metal Casting Parts. |

Quality Control

In order to ensure the quality of the orders, our independent QC members to carry out strict inspection at each stage:

(1) Incoming material inspection (2) Inspection of work-in-progress

(3) Finished product inspection (4) Random warehouse inspections

(3) Finished product inspection (4) Random warehouse inspections

All of our operations are strictly compliant with ISO 9001 guidelines.

We own automated casting lines, CNC machining, CMM inspection, spectrometers and MT testing equipment, X-ray.

We own automated casting lines, CNC machining, CMM inspection, spectrometers and MT testing equipment, X-ray.

Hot Searches