- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V, 50/60HZ

-

Power:

-

28KW

-

Dimension(L*W*H):

-

14500*1850*2350mm

-

Weight:

-

8500

-

Production Speed:

-

100 bags/min or 1600 wipes/min

-

Wet Wipes Material:

-

Spunlace, Flushable, Biodegradable Nonwoven, Hot-rolled, Air-laid

-

Raw Material Weight:

-

35~80gsm

-

Suitable Packing Material:

-

PET/PE, BOPP/PE, PET/AL/PE laminated film and heat-sealable materials

-

Folding Way:

-

Z fold (not pop up or pop up)

-

Unfolded Size:

-

L150-210mm, W140-200mm

-

Folded Size:

-

L75-105mm, W50-100mm

-

Package Size:

-

L130-250mm, W50-100mm, H10-70mm

-

Applied Sticking Label:

-

Transparent Label & Non-transparent Label

-

Product Name:

-

Wet Wipes Machine

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

SUNREE

-

Marketing Type:

-

New Product 2021

-

Voltage:

-

380V, 50/60HZ

-

Power:

-

28KW

-

Dimension(L*W*H):

-

14500*1850*2350mm

-

Weight:

-

8500

-

Production Speed:

-

100 bags/min or 1600 wipes/min

-

Wet Wipes Material:

-

Spunlace, Flushable, Biodegradable Nonwoven, Hot-rolled, Air-laid

-

Raw Material Weight:

-

35~80gsm

-

Suitable Packing Material:

-

PET/PE, BOPP/PE, PET/AL/PE laminated film and heat-sealable materials

-

Folding Way:

-

Z fold (not pop up or pop up)

-

Unfolded Size:

-

L150-210mm, W140-200mm

-

Folded Size:

-

L75-105mm, W50-100mm

-

Package Size:

-

L130-250mm, W50-100mm, H10-70mm

-

Applied Sticking Label:

-

Transparent Label & Non-transparent Label

-

Product Name:

-

Wet Wipes Machine

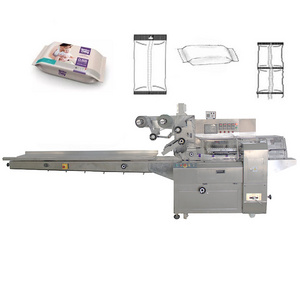

Full Servo Automatic Reciprocate Packing Pop Up Folding Disposable Baby Cleaning Wet Wipes Tissue Paper Making Machine Price

It is not easy to introduce all aspects of

W

et Wipes Machine

in this page, so we have prepared a part of information on this page for you to delve into, you could

Contact Us

for more information about technical, operation, materials, videos, etc.

Product Description

|

Main Features

|

Wet Wipes Production Line

|

|

Process Flow

|

Unrolling raw material → Slit fabric into lanes → Folding → Wetting → Cut in size → Output wet wipe → Auto transport to packaing machine → Unrolling packing film → Printing date → Punching window hole on packing film → Sticking label on window hole → Avoid tear-away labeling → Feeding on the convey belt → Coverage → Centre sealing → End sealing and cutting → Output finished products

|

|

Electric System

|

Electric safety circuit protection

|

|

Control System

|

Multi-axis servo motion controller, full servo motor control

|

|

HMI

|

LCD Color touch screen display interface

|

|

Unwinding Device

|

Independent automatic tension control system

|

|

Auto Splicing

|

Nonwovens and packing film non-stop auto splicing with spliced joint automatic rejection system. Two sets of label applicator which can be operated by auto switch mode or synchronous mode

|

|

Wipes Cutting Module

|

Use screw type flexible cutting blade, without mechanical vibration and shock, increase of service life for cutting blade / (Cutter disk with swing arm)

|

|

Cleaning and Disinfection

|

Hygiene grade design, easy to disassemble conveyor belts which contact with liquid are designed accord with hygiene standard

|

|

Wetting Flow Control

|

Electronic flowmeter control wetting flow, reduce recycle liquid, wetting range 2.5-4.5 times

|

|

Liquid Level Control

|

Electric liquid level sensor control liquid level automatically

|

|

Pipeline Disinfection

|

Pipeline and pump use hygiene grade lowest point drain out design and 3D design standard, no residue and free of dead corner, apply to pasteurization or CIP (Clean In Place)

|

|

Spectral Decomposition Detection

|

Nowoven, label, packing film, wetting weight, packaging on-line monitoring

|

|

End Seal Protection Function

|

Protection function to prevent the end seal device cut onto wet wipes

|

|

Automatic Web Guider (optional)

|

Automatic web guiders for jumbo roll and four lanes after slitting, to ensure high speed stable running and folding accuracy

|

|

Quality Control (optional)

|

Nonwoven stain detection, Metal detection, Checkweigher, Date code & Die cutting & Labelling visual inspection, and automatic sorting reject

|

|

Technical Parameters

|

Wet Wipes Production Line

|

|

Applied Nonwoven Material

|

Spunlace, flushable and biodegradable nonwoven, Air-laid paper, hot-rolled nonwoven, etc.

|

|

Nonwoven Specification

|

Maximum W800mm, Φ1200mm, coreφ76.2mm(3”), online slitting

|

|

Nonwoven Quantity

|

2 rolls of nonwoven, non-stop auto splicing, 1 roll running and another roll standby

|

|

Applied Package Film

|

PET/PE, BOPP/PE, PET/AL/PE laminated film and other heat-sealable materials

|

|

Package Film Specification

|

Maximum W420mm,Φ360mm, coreφ76.2mm(3”)

|

|

Package Film Quantity

|

2 rolls of packing film, non-stop auto splicing

|

|

Applied Label

|

Transparent label & non-transparent label

|

|

Label Specification

|

Maximum W100mm,Φ400mm, coreφ76.2mm(3”), 2 rolls of lable, non-stop switch

|

|

Fold Type

|

Z fold

|

|

Folded Size

|

L75-105mm, W50-100mm

|

|

Unfolded Size

|

L150-210mm, W140-200mm

|

|

Package Size

|

L130-250mm, W50-100mm, H10-70mm

|

|

Production Speed

|

100 packages/min or 1600 wipes/min, whichever comes first

|

|

Machine Size

|

L14500mm, W1850mm, H2350mm

|

|

Power Supply

|

AC380V (Customizable), 50/60Hz, three-phase five-wire, 28KW

|

|

Compressed Air

|

0.6-0.8Mpa, 100L/min

|

|

Machine Weight

|

About 8500kgs

|

|

Optional Devices

|

Nonwoven stain detection system, Metal detector & Checkweigher & Reject, Date code printer, Package visual inspection and reject system

|

|

Lid Applicator (optional)

|

|

|

|

Main Features

|

Full-automatic robot arm lid applicator is a perfect combination of industrial manipulator and machine visual technology. Industrial manipulator with its characterized structure and performance to realize high speed picking up and putting motion. Machine vision system can break the constraints of work environment, working hours, production rate and else. It can realize rapid detection of objects shape, size, pattern and their relative position. Visual system can do online monitoring and recognize the position of sticking label on wet wipes package then measuring position and angle. Robot arm can complete grab lid, spray glue, put lid with high speed in place of labour and repetitive work and apply to various lid shape. It allows user to reduce the amount of labor, improve production efficiency, accuracy and product quality.

|

|

|

Technical Parameters

|

|

|

|

Robot Arm

|

Switzerland Stäubli (optional)

|

|

|

Capping Accuracy

|

Horizontal direction: ±1mm, vertical direction: ±1mm (according to lid shape)

|

|

|

Labelling Accuracy

|

Horizontal direction: ±1mm, vertical direction: ±1mm

|

|

|

Wet Wipe Package Height

|

Maximum 110mm (otherwise indicated)

|

|

|

Applied Lid Size

|

L50-150mm, W50-120mm, H2-10mm

|

|

|

Applied Sticking Label

|

L30-100mm, W30-100mm

|

|

|

Suction Cup Qty

|

1 or 2

|

|

|

Glue Gun Qty

|

1 or 2

|

|

|

Label Applicator Qty

|

2 (auto switch)

|

|

|

Production Speed

|

Maximum 90 pcs/min (according to lid shape) or Maximum 120 pcs/min (according to lid shape)

|

|

|

Machine Size

|

L3850mm,W2400mm,H2630mm

|

|

|

Power Supply

|

AC380V, 50/60Hz, three-phase five-wire, 10KW

|

|

|

Compressed Air

|

0.6-0.8Mpa,100L/min

|

|

|

Machine Weight

|

About 2400kgs

|

|

|

Optional Devices

|

Capping effect visual check & auto reject

|

|

You could also inform us the product what you want to produce, or wish to develop a special new one, we are here to offer our customization support.

Contact Us

now!

Process Flow

Why Choose Us

Dynamic Balance Test

The dynamic balance test of the rotating part is carried out by the domestic advanced balancing machine, according to different speed and loads of the spare parts, to ensure all spare parts are stable during machine running.

Hardness & Heat Treatment Test

The metal material requirement is higher for core parts, so we use new materials at home and abroad, to establish our standard heat treatment processing, and also use hardness testing, to improve hardness of spare parts and increase resistance.

Measure of Precision

Precision testing includes dimensio tolerance and shape tolerance testing, we use specific testing equipment to ensure the accurate of each spare part.

Excellent CNC Processing Ability:

We subcontract processing including turn-milling, five axis, and gantry CNC machining center are introduced from Mazak, Moirisiki and Tsugami in Japan which are the world's most advanced equipment. They realized the high speed, high efficiency, high quality spare parts processing capacity, and ensure equipment parts processing precision and reduce labor costs.

Top Notch Components:

Our machines are characterized by the use of high precision mechanical tooling and full-servo technology with high automation levels. All our projects are shared with customers as well as the production process and final on-site installation. The parts are all come from high quality suppliers, electric appliances are world famous brands, the use of top notch components ensures long-term reliability of the machines and a consistent savin in terms of spare parts and technical intervention.

Factory Show

Certifications

Customer Testimonial

FAQ

Q1. Do you provide customized service?

We can design the machines according your requirements (product type, power, package type and so on), at the same time we will give you professional suggestion by many years industrial experience.

Q2. What’s your guarantee or the warranty of the quality?

We offer you high quality machines with 1 year guarantee and supply life-time technical support.

Q3. What’s your payment term?

30% of total value is required as down payment upon the confirmation of the Contract and 70% to be paid before delivery.

Q4. How about the packaging details?

Standard export packing. As specific requirement, major products using export plywood case packing, small products use thick carton packing, ensure that the product packaging integrity and safety.

Q5. When can I get my machine after I paid?

Normally production time is around 30-60days for wet wipe machine, the exactly depend on what kind of machine you order. The shipping time is based on your destination port.

Q2. What’s your guarantee or the warranty of the quality?

We offer you high quality machines with 1 year guarantee and supply life-time technical support.

Q3. What’s your payment term?

30% of total value is required as down payment upon the confirmation of the Contract and 70% to be paid before delivery.

Q4. How about the packaging details?

Standard export packing. As specific requirement, major products using export plywood case packing, small products use thick carton packing, ensure that the product packaging integrity and safety.

Q5. When can I get my machine after I paid?

Normally production time is around 30-60days for wet wipe machine, the exactly depend on what kind of machine you order. The shipping time is based on your destination port.

Product Portfolio

Hot Searches