- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Han's Laser

-

Cutting Thickness:

-

0-10mm

-

Control Software:

-

Han's SMC

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Han's Laser

-

Weight (KG):

-

17000 KG

-

Laser power:

-

6000W

-

Product name:

-

P6018D

-

Control system:

-

Han's SMC

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

10 m/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Han's Laser

-

Cutting Thickness:

-

0-10mm

-

Control Software:

-

Han's SMC

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Han's Laser

-

Weight (KG):

-

17000 KG

-

Laser power:

-

6000W

-

Product name:

-

P6018D

-

Control system:

-

Han's SMC

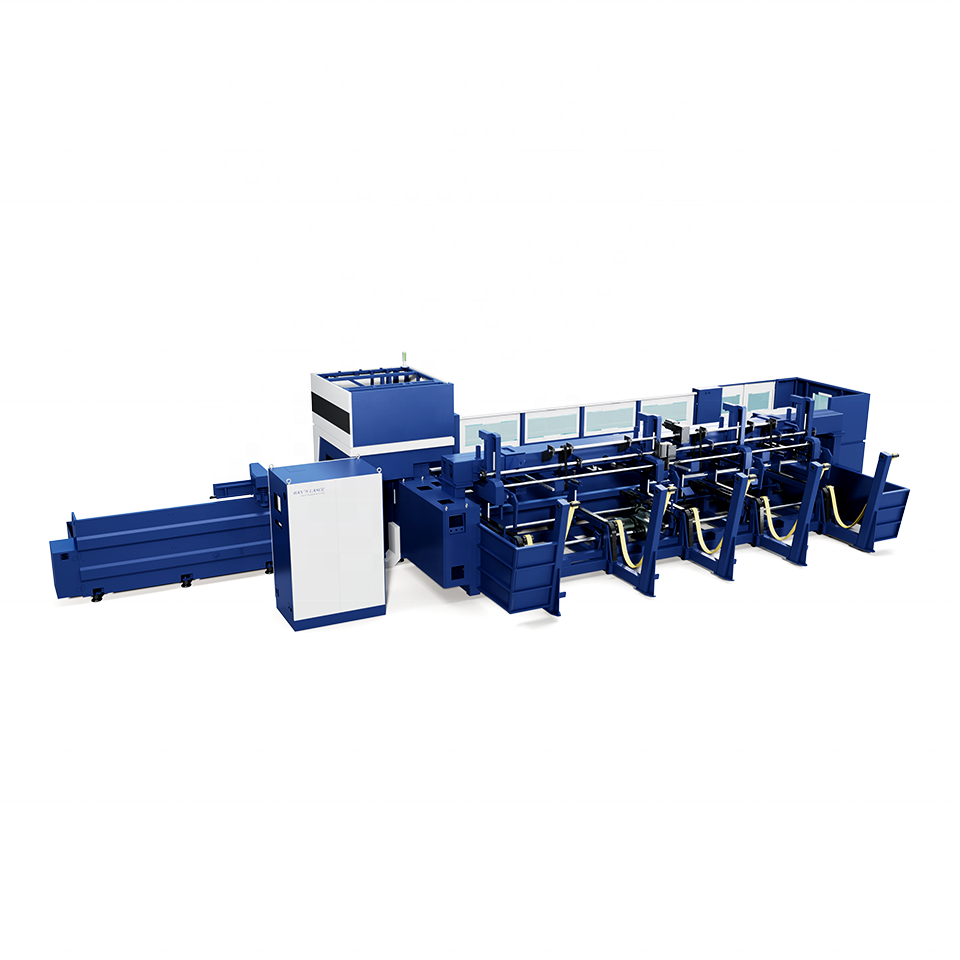

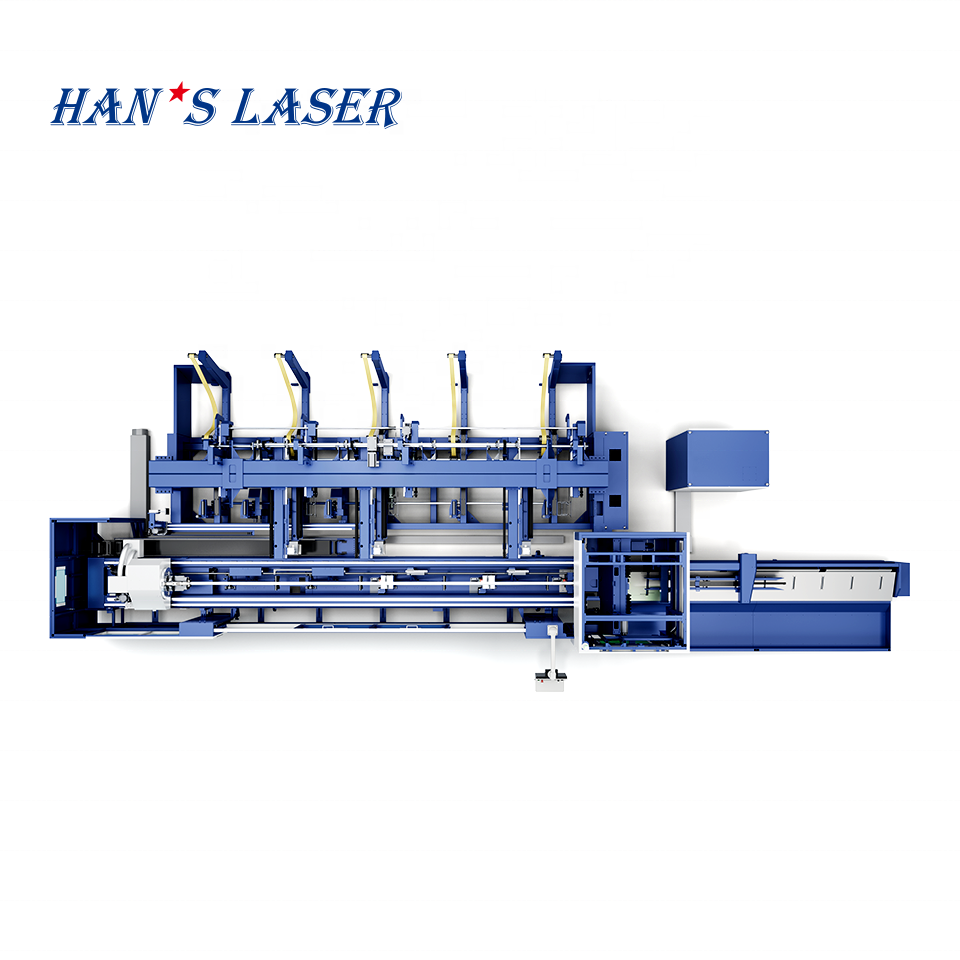

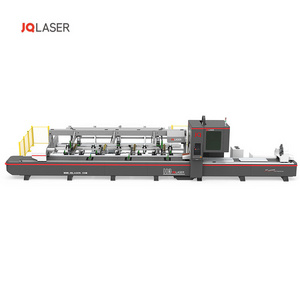

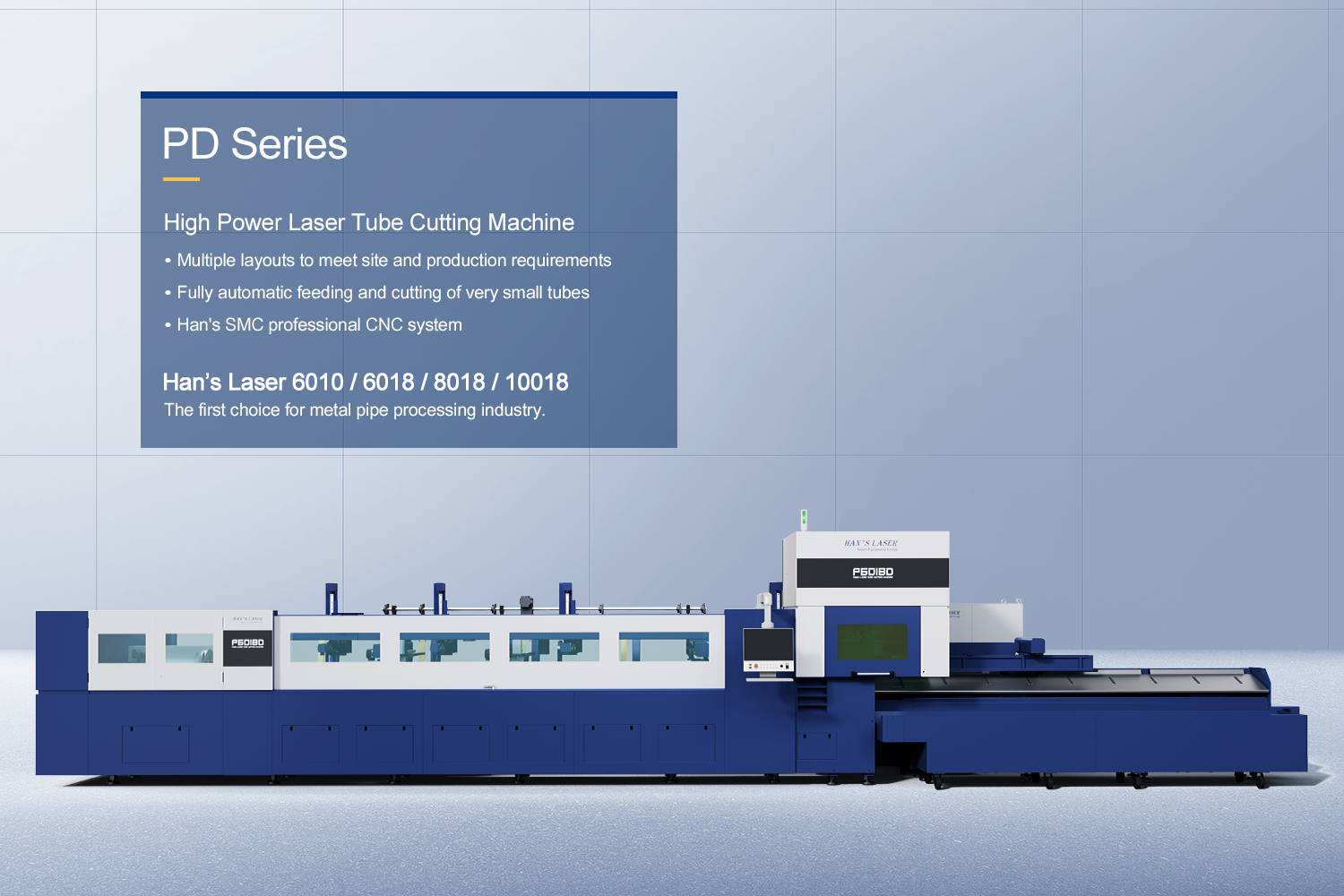

High Precision Han's Laser Automatic 2 chucks P6018D CNC Tube Cutting Machine for Algriculture Industry

Products Description

P6018D:

1.

PD Series fiber laser cutting machine serves as one of the best sales and well-established model, verified by market for a long

term.

2.

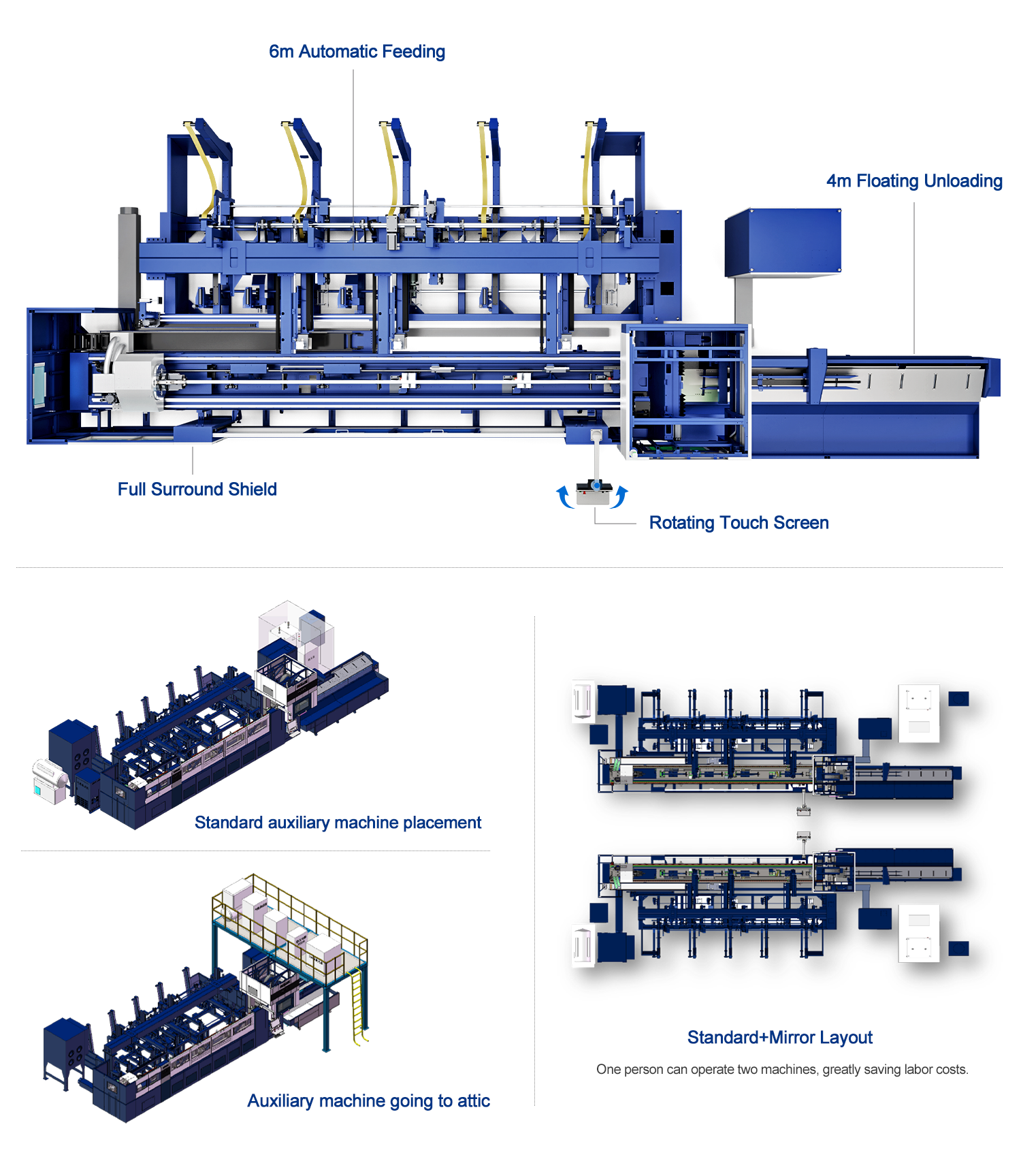

The X, Y and Z linear axes and the A and B rotary axes are all imported from Germany with high torque servo motors. High precision, high rotation, high torque and large inertia ensure high speed and acceleration of the whole machine.

3.

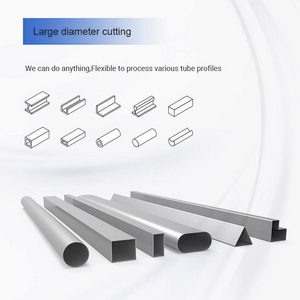

Optional laser-cut functions for channel steel, H shape-tubes, bar section and any other special shaped tubes.

4.

Real-time monitoring, automatic notifications of equipment maintenance, big-data driven management system, let data works for increasing production.

1

. Superior performance.

First-class technology and productivity: the new CNC technology of the Hans series and the open CNC architecture with Intel dual-core CPUs

2. Modular architecture.

1) PC technology: With the standard PC open system, users can integrate their own PC software such as NC programming tools, statistical programs, visualisation programs, etc. on the Hans series CNC.

2) True open CNC: Based on a true open architecture CNC (including the CNC kernel), the user can integrate other specialised technologies and special software (programs written in C++) into the system in a safe and secure manner.

3) High speed machining: High speed machines require very short cycle times (PA up to 7200 program segments/sec) and special control algorithms and communication functions. The "adaptable pre-reading function" will pre-process 1000 program segments in real time and calculate the maximum feed rate within the programmed parameters and limits.

4) The demand for high productivity, high precision and good surface quality is constantly increasing.

5) Comprehensive diagnostic functions for fast fault finding.

6)A wide range of cutting aid gases can be easily converted via the CNC.

7) With a library of expert cutting process parameters from the han’s Laser and a user-friendly expert library parameter interface, the laser cutting process parameters can be modified in real time in the interface.

8) The Ethernet communication interface allows direct communication with the computer to transfer the part program files.

9) With status display and display of the current position.

9)Large storage space on the hard disk, the machining program can be called directly from the hard disk without the limitation of the system memory.

10)Remote diagnosis function, digital servo system. 19″ touch colour LCD display.

Specification

|

Model:

|

P6018D

|

|

Cutting Area:

|

20mm-180mm

|

|

Positioning accuracy (X/Y):

|

±0.03mm/1000mm

|

|

Repeatability(X/Y):

|

±0.03mm

|

|

Positioning Speed (X/Y):

|

120m/min

|

|

Positioning Speed (Z):

|

120rpm

|

|

Cutting Thickness:

|

0-10MM

|

|

Graphic Format Supported:

|

AI, PLT, DXF, BMP, Dst, Dwg, LAS, DXP

|

Hot Searches