*We can send you the video of mechanical operation.

*Welcome to our company, we can show you the equipment in our factory. If you come to China and don't know the location of our

company, you can contact us to pick you up.

*We can design the machines according your requirements.(material ,power,filling type,the kinds of the bottles,and so on

*Professional engineers come to install and debug the machine, and train relevant operators until they can operate the machine

skillfully

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SANOFI

-

Dimension(L*W*H):

-

1750*1550*2250 mm

-

Weight:

-

2000KG

-

Certification:

-

CE,ISO,SGS

-

Name:

-

Mini Mineral Drinking Water Filling Machine / Bottling Plant

-

Capacity:

-

1000-2000bph

-

Control:

-

PLC

Quick Details

-

Packaging Material:

-

Plastic, Mini Mineral Drinking Water Filling Machine / Bottling Plant, For Small Factory, 1000-2000BPH

-

Voltage:

-

220/380

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SANOFI

-

Dimension(L*W*H):

-

1750*1550*2250 mm

-

Weight:

-

2000KG

-

Certification:

-

CE,ISO,SGS

-

Name:

-

Mini Mineral Drinking Water Filling Machine / Bottling Plant

-

Capacity:

-

1000-2000bph

-

Control:

-

PLC

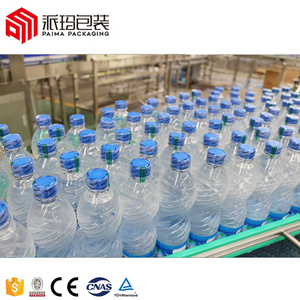

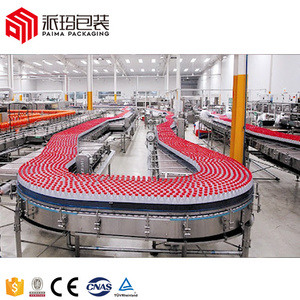

Products Description

The procuction line includes QS automic washer,CYG normal pressure filler ,FXZ cap capping machine ,SSJ carrying machine ect. The key parts for washing,filling and sealing are made of high quality stainless material, with the features of advanced technology,completed system, reliable performance, easy in operation

Details Images

|

Model

|

Capacity

|

Bottle Height

|

Motor Power

|

|

12-12-1

|

2000-3000 B/H

|

160-300mm

|

2.25kw

|

|

18-18-6

|

3000-5000 B/H

|

160-320mm

|

2.95kw

|

|

24-24-6

|

5000-8000 B/H

|

160-340mm

|

3.7kw

|

Feature

1)The machine is mainly used for PET bottled non-carbonated beverage production line,such as spring water and wine drinks.

2)Washing,filling and capping are available in one machine.

3)The contact time between raw materials and the outside world has been reduced to improve the health conditions, production capacity and economic benefits.

2)Washing,filling and capping are available in one machine.

3)The contact time between raw materials and the outside world has been reduced to improve the health conditions, production capacity and economic benefits.

4)The structure of conveying is hanging type and clamping the bottleneck to easily change bottle type.

5)Using the advanced PLC(Programmable Logic Controller) technology.

6)The major electrical apparatus are all products of well-known brands, such as SIEMENS, MITSUBISHI, Schneider and OMRON.

5)Using the advanced PLC(Programmable Logic Controller) technology.

6)The major electrical apparatus are all products of well-known brands, such as SIEMENS, MITSUBISHI, Schneider and OMRON.

Recommend Products

Product packaging

After Sales service

Hot Searches