- Product Details

- {{item.text}}

Quick Details

-

Type:

-

High Performance

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

OCHEM

-

Model Number:

-

EB4160A+EB4160B

-

Type:

-

High Performance

EB4160A/EB4160B Ethyl acetate solvent base polyurethane adhesive

(specializing for Aluminum Foil, VMPET,VMOPP,VMCPP boiling resistant packaging)

Product Description

With excellent anti-medium,

anti-auxiliaries performance , specializing for Aluminum Foil and VMPET,VMOPP,VMCPP 100℃ boiling resistant packaging

anti-auxiliaries performance , specializing for Aluminum Foil and VMPET,VMOPP,VMCPP 100℃ boiling resistant packaging

Widely used in laminating of various treated film like PET, NY, AL, PE, CPP,VMPET,VMOPP,VMCPP , etc.

|

Item

|

EB4160A

(OH component)

|

EB4160B

(NCO component) |

|

Type

|

Main agent

|

Hardener

|

|

Ingredient

|

Polyester polyol agent

|

Isocyanate-terminated Polymer

|

|

Appearance

|

Light yellow transparent liquid

|

Light yellow transparent liquid

|

|

Solid Content(%)

|

60±2

|

75±2

|

|

Viscosity (mPa.s)

|

3000±1000(25℃)

|

2500±1250(20℃)

|

|

Solvent

|

Ethyl acetate

|

Ethyl acetate

|

|

Mix Proportion

|

20

|

4

|

|

Shelf life

|

360days

|

360days

|

Standard

OCHEM EB4160A/EB4160B 2-component EA base polyurethane adhesive are in compliance with the positive lists of the following,internationally accepted guidelines for the production of articles intended to come into indirect contact with food stuff.

- EU RoHS directive (EU) 2015/863 amending Annex II to directive 2011/65/EU

- CFR, title 21, § 175.105 of the FDA, Washington D.C., respectively

- Regulation (EC) No 1907/2006 concerning the REACH

- EU RoHS directive (EU) 2015/863 amending Annex II to directive 2011/65/EU

- CFR, title 21, § 175.105 of the FDA, Washington D.C., respectively

- Regulation (EC) No 1907/2006 concerning the REACH

Features

EB4160A/B is a functional adhesive with very soft colloid

Specializing for Aluminum foil laminating with good peeling strength and high transparency, resist to be boiled at 100℃ less than 40 minutes.

With excellent anti-medium, anti-auxiliaries performance like reducing the influence of smooth agent.

High initial and final bonding strength, good flow property, good coating property to the film, the laminated film have good resistance for film-aging, freezing etc

Specializing for Aluminum foil laminating with good peeling strength and high transparency, resist to be boiled at 100℃ less than 40 minutes.

With excellent anti-medium, anti-auxiliaries performance like reducing the influence of smooth agent.

High initial and final bonding strength, good flow property, good coating property to the film, the laminated film have good resistance for film-aging, freezing etc

Recommended Operation

Recommended Operating Conditions :

Application Method : Direct gravure

Application Cylinder : any types of smooth roller or anilox roller

Application solids : 20-40% (Recommend 30%)

Pot Life : Static 8 hours approximately

Dynamic 24 hours approximately

Dry Coating Weight : 3.0-4.0 gsm depending on structure

Drying Section Temperature : 50-60℃ 60-70℃ 70-80℃(three section)

Laminating Temperature : 50-80℃

Cure Time : 48~96 hours (45-55℃)

Cleaning : Solvent Ethyl Acetate

Application Method : Direct gravure

Application Cylinder : any types of smooth roller or anilox roller

Application solids : 20-40% (Recommend 30%)

Pot Life : Static 8 hours approximately

Dynamic 24 hours approximately

Dry Coating Weight : 3.0-4.0 gsm depending on structure

Drying Section Temperature : 50-60℃ 60-70℃ 70-80℃(three section)

Laminating Temperature : 50-80℃

Cure Time : 48~96 hours (45-55℃)

Cleaning : Solvent Ethyl Acetate

Storage&Safety

Store in cool, dry, well-ventilated area away from heat and ignition sources.

Keep container tightly closed.

Refer to MSDS for more safety

Refer to MSDS for more safety

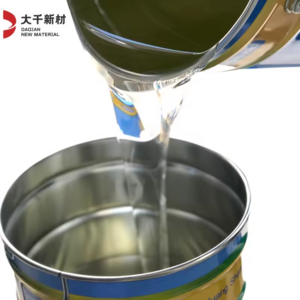

Packing & Delivery

Package

Pack in steel drum normally.

Main agent is 20kg/drum.

Pack in steel drum normally.

Main agent is 20kg/drum.

Hardener is 4.5kg/drum.

Hot Searches