Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Name:

-

PVC WPC door board extrusion line

-

Raw material:

-

PVC Resin

-

Other name:

-

PVC WPC hollow door panel production line

-

Material:

-

PVC

-

Automatic Grade:

-

Fully Automatic

-

Certification:

-

ISO9001:2000

-

Power:

-

100KW

Quick Details

-

Screw Design:

-

Double-screw

-

Place of Origin:

-

Jiangsu, China

-

After-sales Service Provided:

-

Field installation, commissioning and training, Field maintenance and repair service, Online support, Overseas service center available

-

Name:

-

PVC WPC door board extrusion line

-

Raw material:

-

PVC Resin

-

Other name:

-

PVC WPC hollow door panel production line

-

Material:

-

PVC

-

Automatic Grade:

-

Fully Automatic

-

Certification:

-

ISO9001:2000

-

Power:

-

100KW

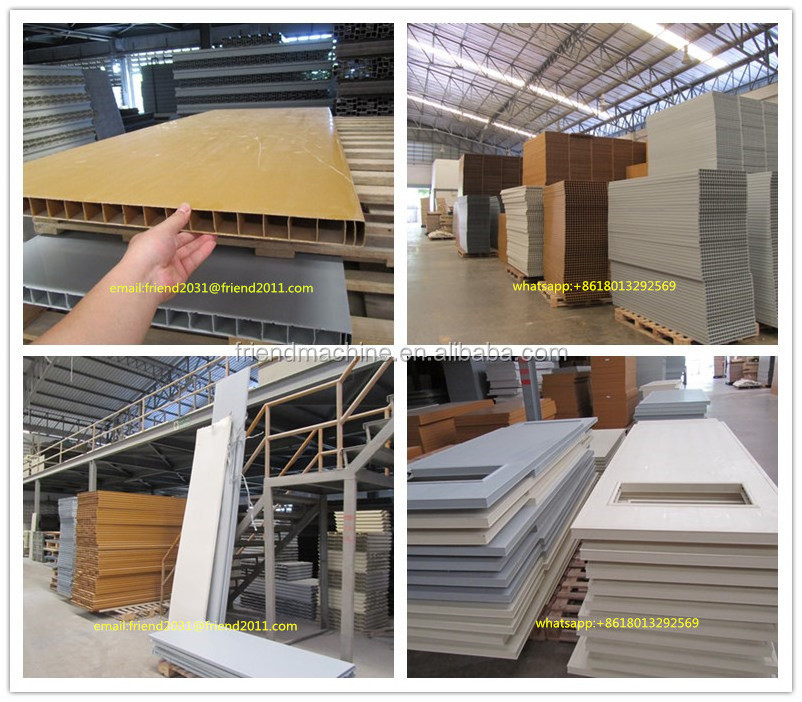

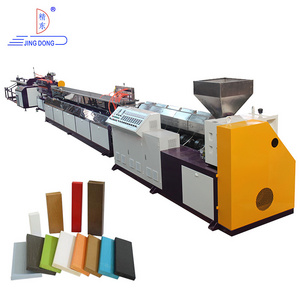

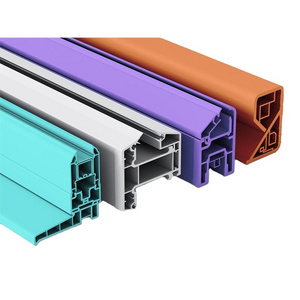

Product Application

bamboo and plastic composite plate/board Production Extruder Machine is mainly used for making PVC plastic profile with different section shape and height. the surface of PVC profile/panel can be treated by printing & coated with glossy oil, or by heat transfer printing, or by lamination, which can make good decoration effect for kitchen,toilet,balcony and so on.

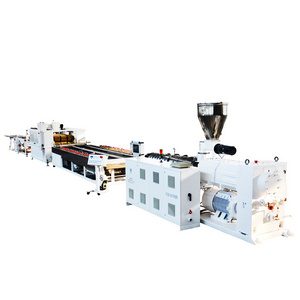

Features of the Machine:

1)Extruder screw and barrel from Zhoushan,with vacuum degassing system, can get rid of the waste gas from the raw material which can ensure good quality of final granules.

2) Gearbox: From Jiangyin gearbox company,very famous brand in China,with nice outline, stable running, low noise and long service time.

3) Heating system: adopting cast aluminum heaters with stainless steel plate covers, wind fan cooling system, ensuring good features of cooling and heating, precision temperature controlling.

4) Driving system: adopting Siemens motor, using ABB inverter which provide stable torque output and various speed.

5) Vacuum calibrating and cooling Table: the tabley is made by #304 stainless steel, good strength and performance,long life time.

6) Traction machines:Rubber block traction belt,traction speed is adjustable by ABB frequency inverter.

7) Cutting machine: saw blade cutting,low noise,quick cutting performance,with dust collection device.

Main Machine Flow Chart

Pre-Sales Service

* We given client the details technician offer.

* Professional advice for Inquiry and technical support.

* supply the details layout, installation instruction, technician support for the clients

* Free Machine testing support.

* View our Factory,sales manager accompany.

* 24 hours English support.

After-Sales Service

* We arrange engineer to install the machinery and training the workers for client abroad if clients required.

* We have 24 hours team to solve problems after sales.

* We have free spare parts with the right machine during warranty time.

* We supply whole machine lifetime spare parts for every customer with low cost after warranty time.

* We always up date the new technology to every customer.

Zhangjiagang Friend Machinery Co., Ltd. is a professional company specializing in the design and manufacture of plastic machines, such as 3D printer filament extrusion line,single screw extruders, conical twin screw extruders, PVC, PE, PP and PP-R pipe extruders, PVC and PE profile extruders, PVC and PE recycling machines, crushing, washing and pelleting machines, conveying and mixing machines for all kinds of plastics and other kinds of auxiliary equipment in the field.

Our company is well known both at home and abroad for high quality products and complete service systems. Our products sell well all over the world.

If you are interested in any of our products, please feel free to contact us for more information.