- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

400 mm

-

Width of Working Table (mm):

-

1800 mm

-

Dimension:

-

3600*1950*2650 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SENFENG

-

Weight (KG):

-

8000

-

Motor Power (kw):

-

7.5 kw

-

Marketing Type:

-

New Product 2022

-

Maximum bending force:

-

1000KN/1300KN

-

Bending length:

-

3200mm

-

Side rack spacing:

-

2600mm

-

After-sales Service Provided:

-

12 Months

-

Material:

-

stainless steel, carbon steel,etc

Quick Details

-

Machine Type:

-

CNC Bending Machine

-

Length of Working Table (mm):

-

3200

-

Slider Stroke (mm):

-

3200 mm

-

Throat Depth (mm):

-

400 mm

-

Width of Working Table (mm):

-

1800 mm

-

Dimension:

-

3600*1950*2650 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SENFENG

-

Weight (KG):

-

8000

-

Motor Power (kw):

-

7.5 kw

-

Marketing Type:

-

New Product 2022

-

Maximum bending force:

-

1000KN/1300KN

-

Bending length:

-

3200mm

-

Side rack spacing:

-

2600mm

-

After-sales Service Provided:

-

12 Months

-

Material:

-

stainless steel, carbon steel,etc

SENFENG 100T CNC Sheet Metal Bending Machines and Press brake to Process Metal Sheet for Sale

1. Introduction

CNC sheet metal bending machines is designed to be user-oriented, which helps to achieve easy and safe operation of the metal sheet bending process. It has a high rigidity frame to ensure long-time service and stable performance. With DELEM-53T system installed, it owns a state-of-the-art complete touch control solution for synchronized press brakes.

2.Technical Parameter

|

Model |

BDE10032 |

BDE13032 |

||||

|

Maximum bending force |

1000KN |

1300KN |

||||

|

Bending length |

3200mm |

|||||

|

Side rack spacing |

2600mm |

|||||

|

Throat depth |

400mm |

400mm |

||||

|

Maximum cylinder stroke |

200mm |

200mm |

||||

|

The distance between the table and the upper beam |

480mm |

480mm |

||||

|

Speed |

Get down speed:180mm/s Working speed:0-10m/s Return speed:160mm/s |

|||||

|

Main motor power |

7.5KW |

7.5KW |

||||

|

Dimensions |

3600*1950*2650 mm |

3600*1950*2650 mm |

||||

|

Weight |

7.9T |

8.5T |

||||

3. Main Features

- High Strength Machine Bed

The tensile strength and compressive strength of the main structure and the parallel lines of the table top deflection are all within the safe range.

This machine adopts Q235B steel plate, and all the joints of the steel plates have grooves to ensure the strength of the whole machine.

The whole machine is annealed and stress relieved to ensure rigidity, strength, precision and structural stability.

The precision gantry milling machine processes the machine at one time to ensure the parallelism and verticality of each installation part.

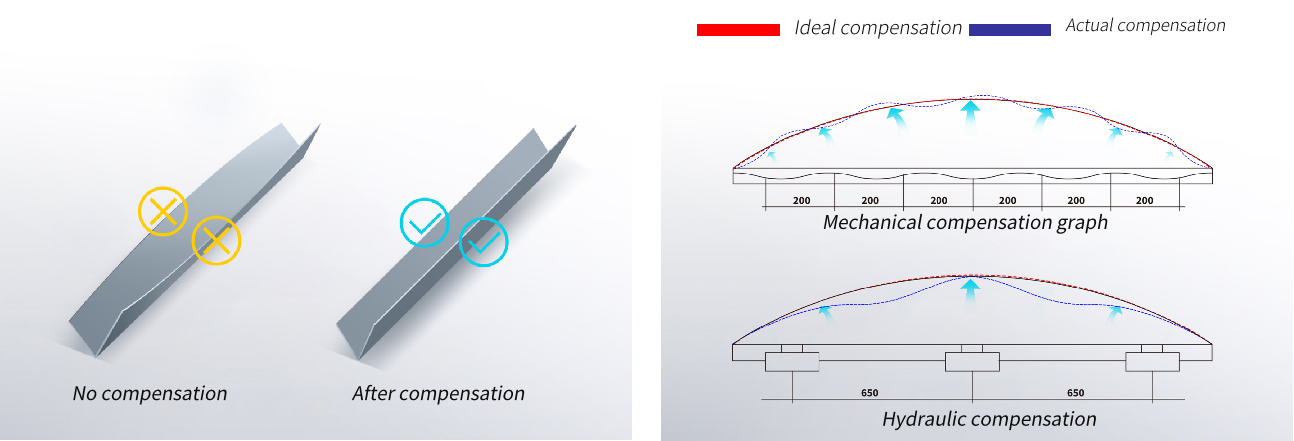

- Mechanical Deflection Compensation System (V axis)

Press brake is composed of unique processed and heat-treated wedge blocks. The relative displacement compensation of each group of wedge blocks is designed according to the force and deformation of the upper beam and the lower beam during work. The numerical control system can calculate the compensation amount required for the upper and lower beams according to the load force when the workpiece is bent, and automatically control the relative movement of the wedge blocks, which can effectively compensate the deflection and deformation of the upper and lower beams.

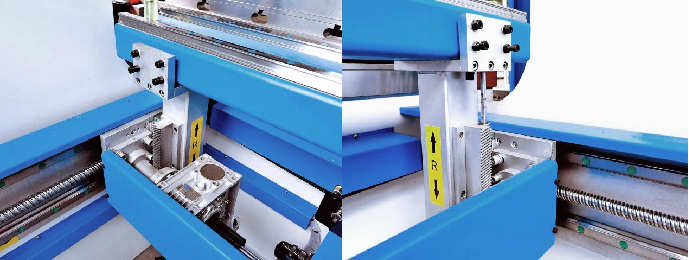

- Backgauge System and Backgauge Fingers

Backgauge System

The back gauge system is one of the important components of a p ress brake , which can ensure the bending product size and straightness accuracy.

The high-precision back gauge system adopts high-precision worm and worm gear as the transmission mechanism. The fastest speed of the X-axis is as high as 500mm/s, which is 1.5 times the speed of the same industry.

Backgauge Fingers

The sheet metal bending machine adopts the anti-collision rear finger products designed and developed by our company.

The fingers can be switched at will, which is convenient for customers to replace at any time according to the wear of the fingers.

CNC sheet metal bending machine can be used to bend stainless steel, carbon steel/galvanized sheet/fluoraluminum zinc sheet, copper, aluminum (the picture below shows various types of bending effects).

SENFENG LASER has four standardized intelligent equipment manufacturing bases. We provide high-end intelligent laser equipment and solutions with a number of fully automated production equipment and perfect quality and pioneering efficiency.

SENFENG LASER is a professional manufacturer engaged in the research, development, production, sales and service of fiber laser cutters, fiber laser cleaning machine, laser welding machine, 3D robot, press brake bending machine and metal sander,etc.

SENFENG LASER has established 2 subsidiaries in United States,Germany and 4 service centers in India,Pakistan,Serbia and Vietnam with perfect quality and service,to provide localized services and technical support for global customers.

Q: How can I choose the most suitable machine?

A: In order to recommend you the most suitable machine model, just tell us below information

1.What is your material

2.The size of material

3.The thickness of material

Q: How can I get the information and quotation of this product quickly?

A: Please leave your email ,WhatsApp or wechat , and we will arrange the sales manager to contact you asap.

Q: What's material can fiber laser cut?

A: All kinds of metal, such as Stainless Steel,Carbon Steel, Mild Steel, Galvanized Steel, Aluminum, copper, etc.

Q: This is the first time I use this kind of machine, is it easy to operate?

A: The machine is mainly controlled by software.Simple, not complicated.Before delivery, we will make a simple operation manual and videos.Generally speaking, an operator who is not familiar with the fiber laser machine can still operate it well.According to customer requirements, we can send technicians to the customer's factory for machine training, or the customer to come to our factory for machine training.

Q: If there is a problem with the machine, what about the after-sales service?

A: 1)The warranty of laser source is 2 years.

2)The warranty of the machine is 2 years(main spare parts),except for the consumable parts such as ceramic ring, focus lens, nozzle etc. Warranty counts from the date marked on the label of the laser source and machine.

3)Except the damage artificially, seller is responsible for offering the fittings free of charge during the warranty period.

4)Exceeding the warranty period, parts need to be repaired or changed, shall be paid.