- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Finol

-

Product Name:

-

Gypsun cornice molds

-

Style:

-

European\Modern\Middle East\Africa

-

Usage:

-

Household Appliance

-

Package:

-

wooden boxes

-

MOQ:

-

1pic

-

Mould Life:

-

3years

-

Length:

-

2000-2500mm

-

Width:

-

110mm,120mm,130mm,150mm and so on

-

Delivery Time:

-

7-15 Days

-

Feature:

-

Easy to use

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Finol

-

Model Number:

-

Finol

-

Product Name:

-

Gypsun cornice molds

-

Style:

-

European\Modern\Middle East\Africa

-

Usage:

-

Household Appliance

-

Package:

-

wooden boxes

-

MOQ:

-

1pic

-

Mould Life:

-

3years

-

Length:

-

2000-2500mm

-

Width:

-

110mm,120mm,130mm,150mm and so on

-

Delivery Time:

-

7-15 Days

-

Feature:

-

Easy to use

Products Description

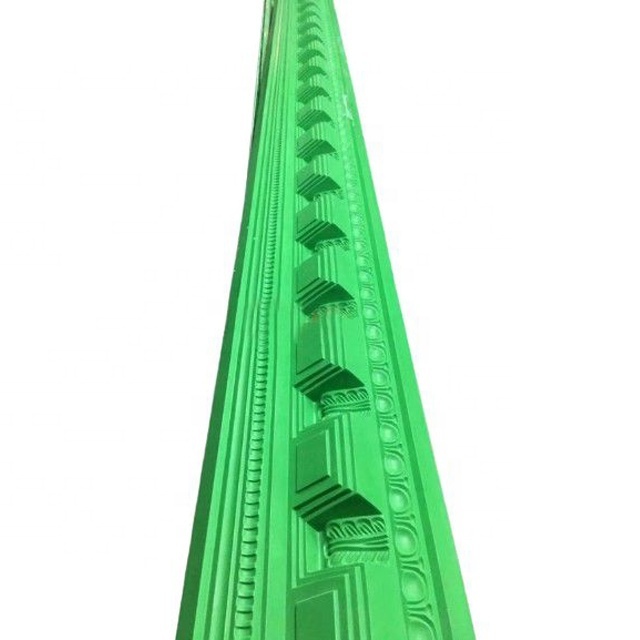

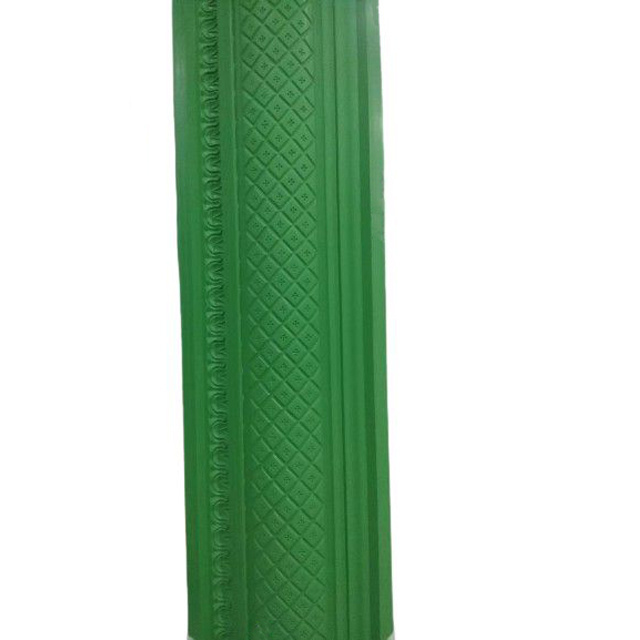

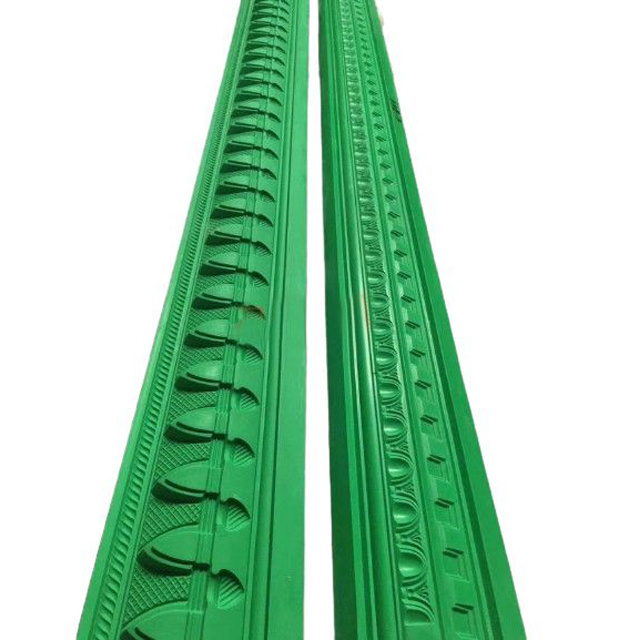

Inxterior Construction Molds

For interior decoration molds, we supply handmade fiberglass gypsum cornice molds, lamp panel molds, ceiling molds, wall panel molds, gypsum corbel molds, interior pillar molds, gypsum corner molds and so on. Operate easily, suitable for small and mid scale factories.

Whats more, for mass gypsum cornice manufacturing, we supply gypsum cornice production equipment and aluminum ally molds. Capacity up to 200-4000pieces/day.

|

Product Name

|

|

Gypsum cornice molds

|

|

|

|||

|

Product Material

|

|

Fiberglass, Silicone rubber, fiberglass, Aluminum alloy

|

|

|

|||

|

Mold Life

|

|

3years

|

|

|

|||

|

Application

|

|

Garden, Hotels, Malls, Schools, Hospitals, Courtyards, Parks and Villas Decoration

|

|

|

|||

|

Advantage

|

|

1. We can provide numerous references attesting to our high standards of professionalism and reputation in the global market place.

2. We have a strong capital base and we can provide free samples as your requirements.

3. We will continue to expand our core business activities and product line through our highly-trained human resources.

4. We actively seek co-operation arrangements with interested international ceiling manufacturer. |

|

|

|||

Details Images

Recommend Products

Manufacturing Process

1.Use a brush to clean the mold in hot water of forty to fifty degrees until the plastic film on the surface of the mold is cleaned

2.Pour a layer of prepared plaster liquid on the mold

3.Sprinkle a layer of glass fiber evenly; and then Pour another layer of plaster liquid and spread it evenly, finally Plus a layer of asbestos netting (If need)

6.After adding a lanyard on one side, pour the plaster liquid into the mold and fill it up

7.Scrape the plaster liquid repeatedly with the matching scraper until completely smoothed

8.Demoulding after solidification, and then Hang the finished product in a cool place and do not expose it to the sun

Packaging

1.Regular: Each fibreglass mold is packed into plastic bag, corners with foam paper to protect.

2.Wooden: 10-20 pieces fibreglass molds are packed into the wooden boxes, so that it is convenient for delivery.

3.Delivery: With our good finish and strong package, we can guarantee that there is no any damage during the transportation.

Hot Searches