- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

XR

-

Dimension(L*W*H):

-

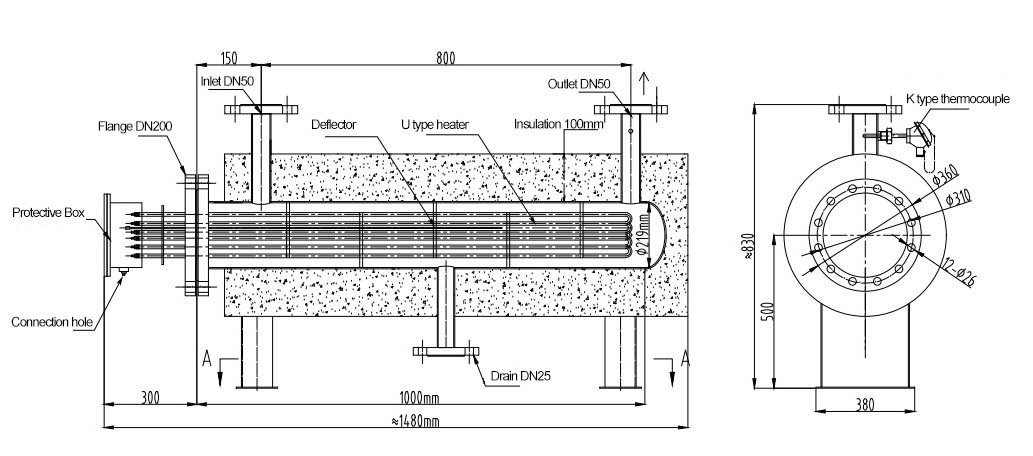

1250*285*585

-

Weight:

-

150 KG

-

Working Temperature Range:

-

0 - 600 ℃

-

Core Components:

-

Heating elements

-

Product name:

-

pipeline heater

-

Voltages available:

-

110V-600V

-

Power:

-

5KW-1000KW

-

Heating medium:

-

liquid or gas

-

After-sales Service Provided:

-

Online Support

-

Sheath material:

-

Carbon Steel or stainless steel

-

Working temperature:

-

0-600C

-

Heating method:

-

Electric heating

-

Packaging:

-

Wooden package

Quick Details

-

Type:

-

water heater, oil heater, air heater

-

Power Source:

-

Electric

-

Voltage:

-

110V-600V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

XR

-

Dimension(L*W*H):

-

1250*285*585

-

Weight:

-

150 KG

-

Working Temperature Range:

-

0 - 600 ℃

-

Core Components:

-

Heating elements

-

Product name:

-

pipeline heater

-

Voltages available:

-

110V-600V

-

Power:

-

5KW-1000KW

-

Heating medium:

-

liquid or gas

-

After-sales Service Provided:

-

Online Support

-

Sheath material:

-

Carbon Steel or stainless steel

-

Working temperature:

-

0-600C

-

Heating method:

-

Electric heating

-

Packaging:

-

Wooden package

Product Description

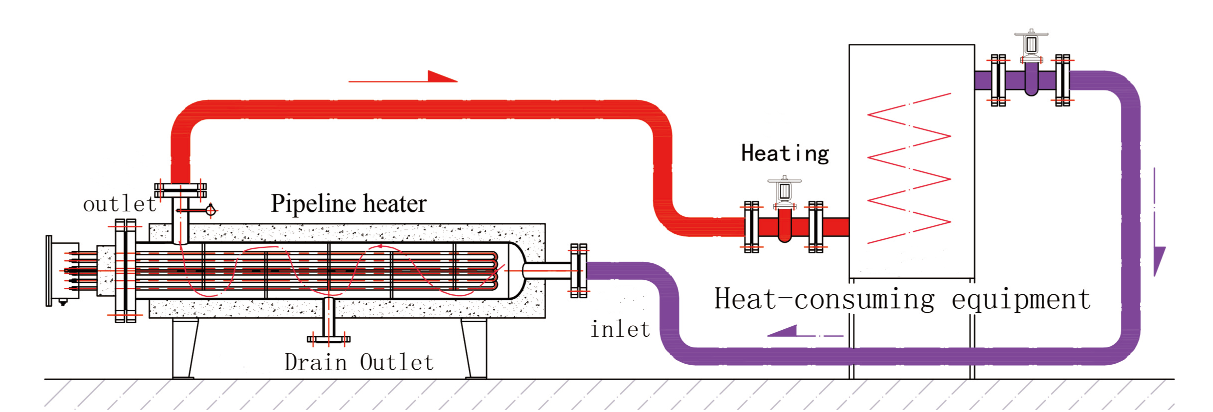

The pipeline heater is an energy-saving equipment that preheats the heating medium. It is installed before the heating medium equipment to directly heat the medium, so that it can circulate heating at high temperatures, and finally achieve the purpose of saving energy. It is widely used in the pre-heating of fuel oil such as heavy oil, asphalt, and clear oil. The pipeline heater is composed of a body and a control system. The heating element is made of seamless stainless steel pipe as a protective sleeve, high temperature resistance alloy wire and high-purity crystalline magnesium oxide powder, processed by a compression process, and the

control part adopts advanced digital Circuits, integrated circuit triggers, etc. constitute an adjustable temperature measurement and constant temperature system to ensure the normal operation of the electric heater.

control part adopts advanced digital Circuits, integrated circuit triggers, etc. constitute an adjustable temperature measurement and constant temperature system to ensure the normal operation of the electric heater.

Features:

1. Heat efficient is more than 95%

2. Vertical type pipeline heater covers a small area but has a height requirement.The horizontal type covers a large area but has no height requirement.

3. The materials of pipeline heater are: carbon steel, stainless steel SUS304, stainless steel SUS316L, stainless steel 310S, etc. Choose suitable materials according to different heating process requirements.

4. Pipeline heaters are heated by flanged electric tubes and equipped with professionally designed

deflectors to ensure that the electric heating tube generates heat evenly and the heating medium fully absorbs heat.

deflectors to ensure that the electric heating tube generates heat evenly and the heating medium fully absorbs heat.

5. For high temperature requirements (the temperature of the air outlet is greater than 600 degrees), use a high temperature resistant stainless steel 310S electric radiation heating tube for heating, and the temperature of the air outlet can reach 800 ℃.

Specification

|

Material

|

Carbon steel/ SS304/ Titanium

|

|

Rated Volatge

|

≤660V

|

|

Rated Power

|

5-1000KW

|

|

Processing Temperature

|

0~800 degree celsius

|

|

Design Pressure

|

0.7Mpa

|

|

Heating Medium

|

Air, water, heavy oil, asphalt etc.

|

|

Heating Element

|

Stainless steel immersion heater

|

Structure

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Application

Pipeline heaters are widely used in automobiles, textiles, printing and dyeing, dyes, papermaking, bicycles, refrigerators,

washing machines, chemical fiber, ceramics, electrostatic spraying, grain, food, pharmaceuticals, chemicals, tobacco and other industries to achieve the purpose of ultra-fast drying of the pipeline heater. Pipeline heaters are designed and engineered for versatility and are capable of meeting most applications and site requirements.

washing machines, chemical fiber, ceramics, electrostatic spraying, grain, food, pharmaceuticals, chemicals, tobacco and other industries to achieve the purpose of ultra-fast drying of the pipeline heater. Pipeline heaters are designed and engineered for versatility and are capable of meeting most applications and site requirements.

Hot Searches