- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

JNBAN

-

Marketing Type:

-

New Product 2023, Ordinary Product

-

Dimension(L*W*H):

-

Customization

-

Capacity:

-

300-2000L, 1000-5000 litres

-

Weight:

-

2000

-

Inner Material:

-

stainless steel, 304 306 Stainless steel

-

Outer Material:

-

stainless steel

-

Design Pressure(MPa):

-

1.2 MPa

-

Design Standard:

-

ASME

-

Working Temperature(℃):

-

10 - 30 ℃

-

Standard:

-

ISO 9001, ASME, CE

-

safety:

-

double safety valve

-

Color:

-

according to customers request

-

air outlet port flange diamete:

-

80-500mm

-

air inlet port thread:

-

rp1-6 inch

Quick Details

-

Volume (m³):

-

1-500m3

-

Max Working Pressure(MPa):

-

1.2 MPa

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

JNBAN

-

Marketing Type:

-

New Product 2023, Ordinary Product

-

Dimension(L*W*H):

-

Customization

-

Capacity:

-

300-2000L, 1000-5000 litres

-

Weight:

-

2000

-

Inner Material:

-

stainless steel, 304 306 Stainless steel

-

Outer Material:

-

stainless steel

-

Design Pressure(MPa):

-

1.2 MPa

-

Design Standard:

-

ASME

-

Working Temperature(℃):

-

10 - 30 ℃

-

Standard:

-

ISO 9001, ASME, CE

-

safety:

-

double safety valve

-

Color:

-

according to customers request

-

air outlet port flange diamete:

-

80-500mm

-

air inlet port thread:

-

rp1-6 inch

The Marked Prices Of Our Products Are All Range Prices Of The Entire Product Series.

If You Need a Detailed Quotation,

Please Send An Inquiry

At The Bottom Of The Page.

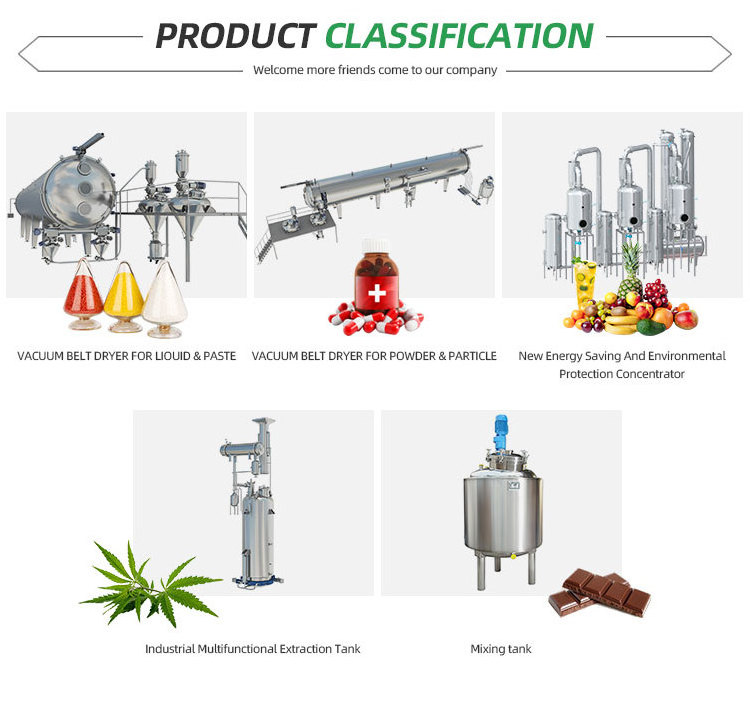

Application

Products Description

stainless steel ASME high pressure vacuum jacket heat chemical mixing mixer tank price reactor pressure vessel

ASME Pressure Vessel: Also known as an ASME boiler, is any pressure vessel bearing the ASME mark. The ASME mark indicates that thecontainer has been inspected and meets the strict ASME VIII code standards. In addition, the ASME mark provides end users with information about ASME certified pressure vessels and their manufacturers.

Working principle:

ASME pressure vessels are widely used in the fields of petroleum, chemicals, rubber, pesticides, dyes, medicine and food. They are pressure vessels used to complete vulcanization, nitration, hydrogenation, hydrocarbonization, polymerization, condensation and other processes. Its structure generally consists of a kettle body, a transmission device, a stirring device, a heating device, a cooling device, a sealing device, a support, etc. Agitators include anchor type, frame type, paddle type, turbine type, scraper type, and combined type. Heating and cooling can use jackets, half pipes, coils, honeycomb panels and other structures. Heating methods include: steam, electric heating, and thermal oil. Supports include leg-type, ear-type and support-type supports to meet the process needs of different working environments such as acid resistance, high temperature resistance, wear resistance and corrosion resistance.

Definition

In ASME (American Society of Mechanical Engineers), pressure vessel regulations are mainly defined by the ASME Boiler and Pressure Vessel Code (ASME Boiler and Pressure Vessel Code). According to this specification, a pressure vessel refers to a container used to store or transport gas, liquid or steam containing internal pressure.

The ASME code classifies pressure vessels based on their design working pressure (Design Pressure). According to the definition of the ASME Code, a vessel can be classified as a pressure vessel when its design working pressure exceeds 15 psi (pounds per square inch, approximately 1.03 bar).

The ASME Code divides pressure vessels into different categories and divisions and provides detailed requirements and guidelines for their design, manufacture, inspection and use. These requirements include container material selection, construction, strength calculation, welding requirements, non-destructive testing, pressure testing, etc. to ensure the safety and reliability of pressure vessels.

The ASME code classifies pressure vessels based on their design working pressure (Design Pressure). According to the definition of the ASME Code, a vessel can be classified as a pressure vessel when its design working pressure exceeds 15 psi (pounds per square inch, approximately 1.03 bar).

The ASME Code divides pressure vessels into different categories and divisions and provides detailed requirements and guidelines for their design, manufacture, inspection and use. These requirements include container material selection, construction, strength calculation, welding requirements, non-destructive testing, pressure testing, etc. to ensure the safety and reliability of pressure vessels.

Product Paramenters

Features

High strength and durability: ASME pressure vessels are made of stainless steel material, which has high strength and corrosion resistance. They are able to withstand working environments under high pressure and extreme conditions, ensuring stable and safe operation of industrial processes.

Diverse applications: ASME pressure vessels are widely used in various industries. They are used to store and transport gases, liquids or chemicals and provide essential products and services to the petroleum, chemical, energy, pharmaceutical and other industries. Whether storing liquefied gas, supplying industrial gases, or serving as nuclear reactor vessels in nuclear power plants, pressure vessels play an important role.

Space efficiency and energy conservation: ASME pressure vessels are typically designed to be compact, allowing efficient use of space. Compared with traditional storage methods, such as bulk storage, pressure vessels can save a lot of space and improve storage efficiency. In addition, ASME pressure vessels can reduce energy consumption and efficiently utilize heat energy.

Diverse applications: ASME pressure vessels are widely used in various industries. They are used to store and transport gases, liquids or chemicals and provide essential products and services to the petroleum, chemical, energy, pharmaceutical and other industries. Whether storing liquefied gas, supplying industrial gases, or serving as nuclear reactor vessels in nuclear power plants, pressure vessels play an important role.

Space efficiency and energy conservation: ASME pressure vessels are typically designed to be compact, allowing efficient use of space. Compared with traditional storage methods, such as bulk storage, pressure vessels can save a lot of space and improve storage efficiency. In addition, ASME pressure vessels can reduce energy consumption and efficiently utilize heat energy.

FAQ

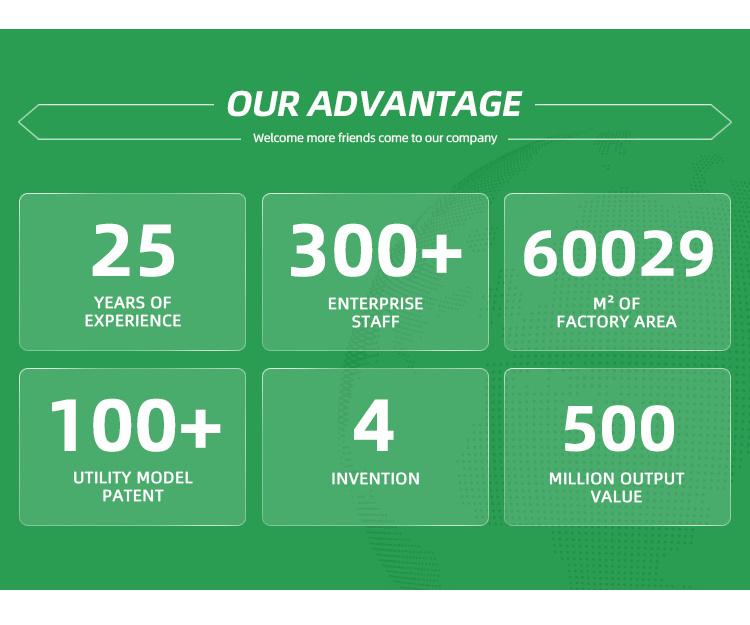

Q: Where is Your Factory? How Can I Visit Your Factory?

A:Our Factory is Located on WenZhou Zhejiang Province. We Are Warmly Welcome You to Visit Our Factory if You Have a Travel Plan

A: If you don't mind, you can send a sample and we test it on the machine. During that time, we will take video and clear

picture for you. If chance, we can take video online and show you.

Q: Is there any installation direction after we received the machine?

A: Yes, we have a professional technical team and warm after service. We will solve any problem you meet during the installation and packing production in time.

Q: Is there any ensurance to guarantee my order from your company?

A: We are an onsite check company from Alibaba, and the quality, delivery time, your payment are all ensured by Alibaba trade assurance.

The machine will have one year warranty. During the warranty year if any of the parts broken not by man-made. We will free charge to replace the new one to you . The warranty will begin after the machine send out and we received the B/L

A:Our Factory is Located on WenZhou Zhejiang Province. We Are Warmly Welcome You to Visit Our Factory if You Have a Travel Plan

A: If you don't mind, you can send a sample and we test it on the machine. During that time, we will take video and clear

picture for you. If chance, we can take video online and show you.

Q: Is there any installation direction after we received the machine?

A: Yes, we have a professional technical team and warm after service. We will solve any problem you meet during the installation and packing production in time.

Q: Is there any ensurance to guarantee my order from your company?

A: We are an onsite check company from Alibaba, and the quality, delivery time, your payment are all ensured by Alibaba trade assurance.

The machine will have one year warranty. During the warranty year if any of the parts broken not by man-made. We will free charge to replace the new one to you . The warranty will begin after the machine send out and we received the B/L

Hot Searches