- Product Details

- {{item.text}}

Quick Details

-

Material:

-

HT250-300 QT450-600

-

Hardness:

-

HB170-240

-

Tempering temperature:

-

600-700 degrees

-

Roughness:

-

Ra0.8-3.2

-

Weight error:

-

5%

-

Density:

-

7.3-7.85

-

Accuracy:

-

1.2.3

-

Application:

-

Machine made

-

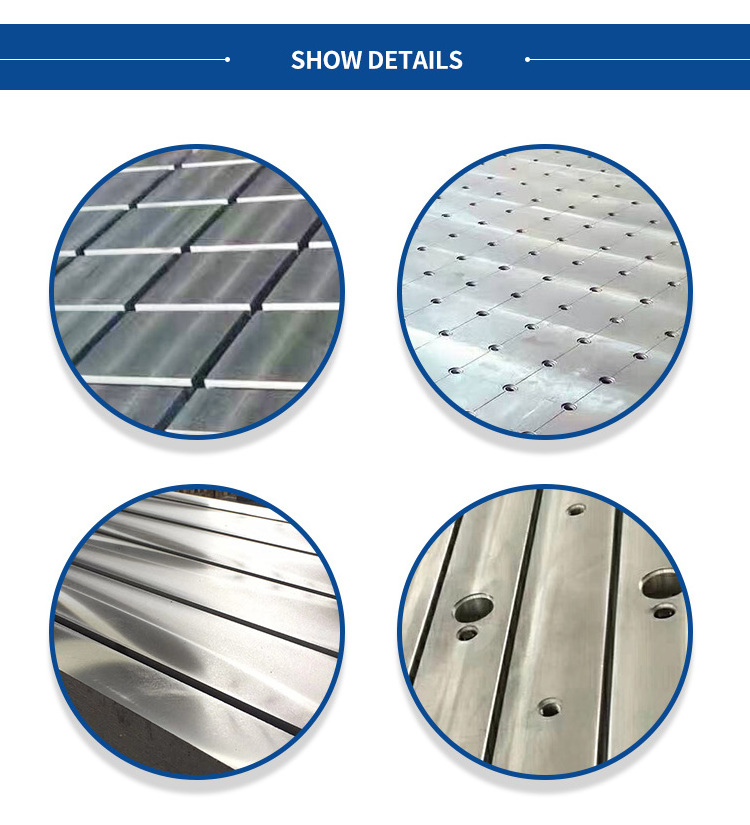

Work surface treatment:

-

Grinding process

-

Aging treatment:

-

Two artificial tempering aging

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Desheng

-

Model Number:

-

A

-

Material:

-

HT250-300 QT450-600

-

Hardness:

-

HB170-240

-

Tempering temperature:

-

600-700 degrees

-

Roughness:

-

Ra0.8-3.2

-

Weight error:

-

5%

-

Density:

-

7.3-7.85

-

Accuracy:

-

1.2.3

-

Application:

-

Machine made

-

Work surface treatment:

-

Grinding process

-

Aging treatment:

-

Two artificial tempering aging

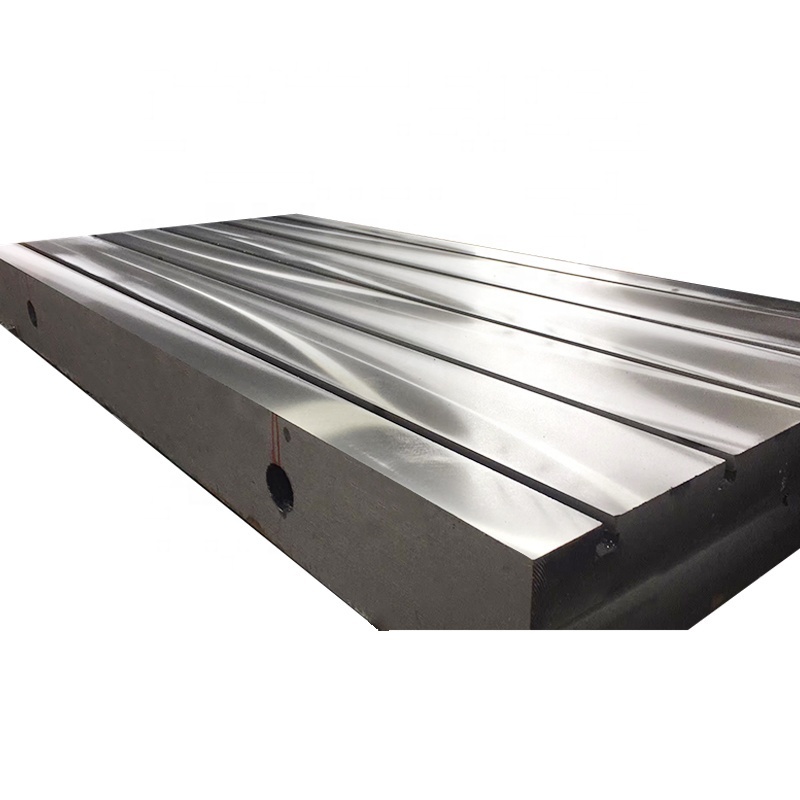

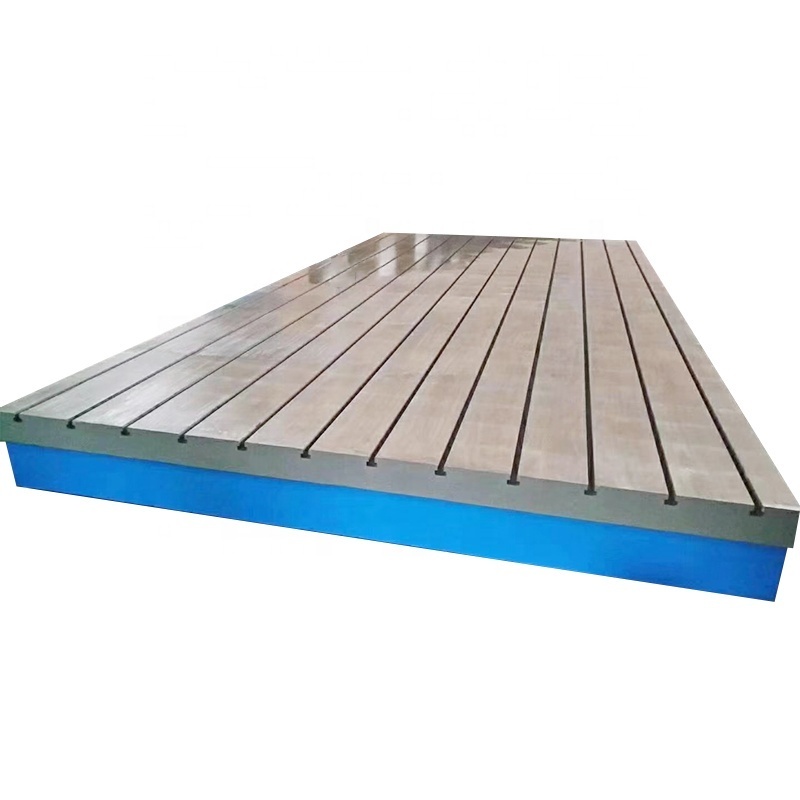

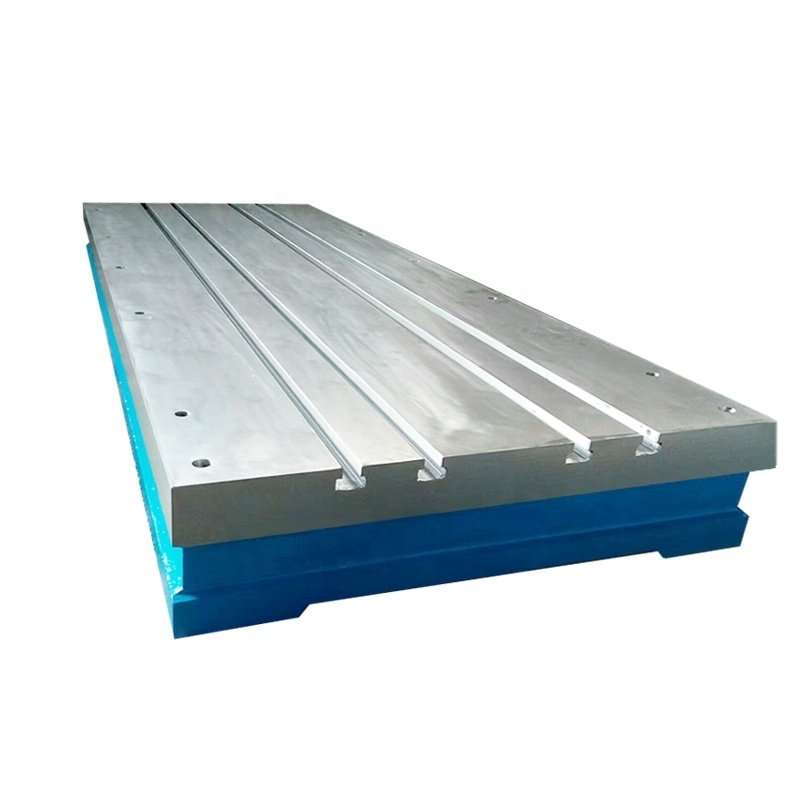

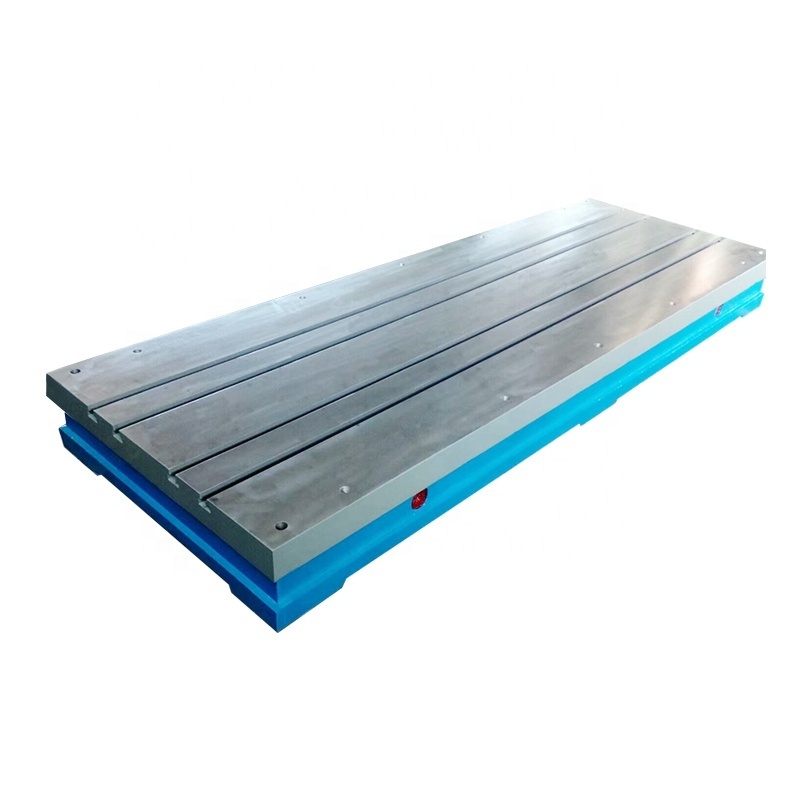

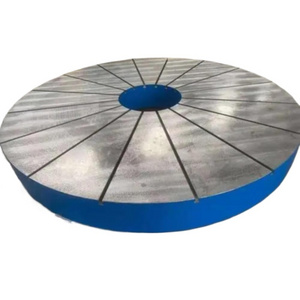

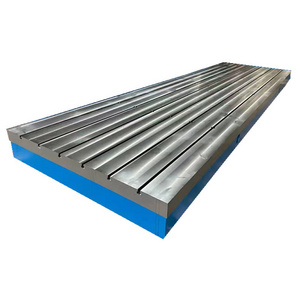

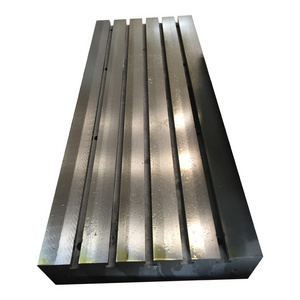

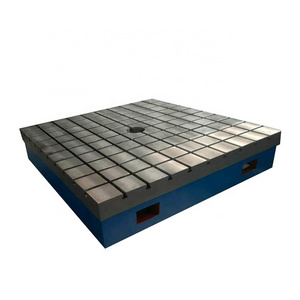

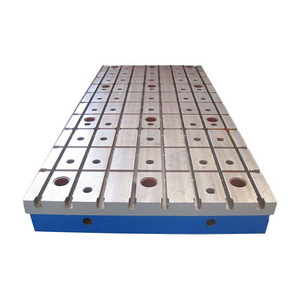

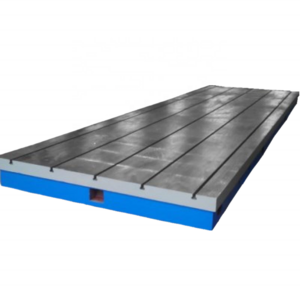

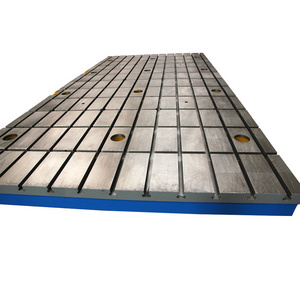

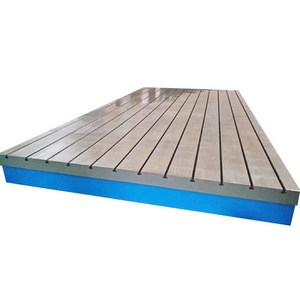

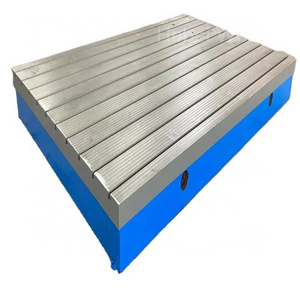

The cast iron platform is referred to as the platform, which is also called the cast iron plate. That is the basic plane reference measuring tool for workpiece inspection, scribing, debugging equipment, assembly, welding and riveting. Cast iron platforms are classified into 0, 1, 2 and 3 according to accuracy levels. Generally, Class 0, Class 1, and Class 2 plates are used as flat plates for inspection platforms. Platforms for Class 3 are used for scribing, assembly, welding, and riveting. They are widely used in machinery manufacturing, chemical engineering, hardware, aerospace, petroleum, automobile manufacturing, Instrumentation manufacturing and other industries.

Cast iron platform installation support accessories: platform brackets, adjustment horns, ground anchors, jacks, etc. When installing, it should be adjusted to the level and the load is distributed on each fulcrum. When the ambient temperature is used, vibration should be avoided.

Attached form information :

| Material | Size(mm) | Height(mm) |

| HT200--300 | 1500*1000——2000*4000 | 230——300 |

| HT200--300 | 2000*5000—3000*6000 | 300——400 |

The appearance of the cast iron platform is basically a box type. It consists of three parts: working surface, side wall and rib plate. Each part is made by one casting. The thickness of the work surface is the most critical, not only to ensure that the effect is not too thick, but also the price is high, but also the surrounding and ribs. The circumference plays a supporting role in use. The thickness and height are closely related to the platform support ability. For the stretching effect, the height and thickness of the reinforcing ribs should also be designed according to the bearing requirements. The height of the reinforcing ribs is usually half gluten, full ribs and flat ribs.

- According to the latest standard of China's national cast iron platform: GB/T 22095-2008

- Acceptance: JJG117-2005

- Gray iron casting: GB9439 — 88

- Iron dimension tolerance: GB6414-86

- Material: According to GB/4986-85. The material is generally HT200--300, also has QT400-600, ZG15-45.

- Other requirements are in accordance with the corresponding national standards and industry standards.

- First aging treatment: clear sand, natural release, annealing degaussing.

- Roughing: sand removal, rough milling, rough planing, six faces. Leave the finishing allowance to check whether the blank has casting defects, whether it meets the relevant technical requirements of the national standard, etc.

- Secondary tempering to stress, vibration aging to remove residual stress.