- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Pinliang

-

Voltage:

-

380V

-

Power:

-

28.5KW

-

Dimension(L*W*H):

-

3500*1500*1700mm

-

Weight (KG):

-

2500

-

Maximum groove depth:

-

130mm

-

Maximum groove length:

-

2000mm

Quick Details

-

Application:

-

Furniture Factory

-

Motor Speed:

-

2840rpm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Pinliang

-

Voltage:

-

380V

-

Power:

-

28.5KW

-

Dimension(L*W*H):

-

3500*1500*1700mm

-

Weight (KG):

-

2500

-

Maximum groove depth:

-

130mm

-

Maximum groove length:

-

2000mm

Machine Description

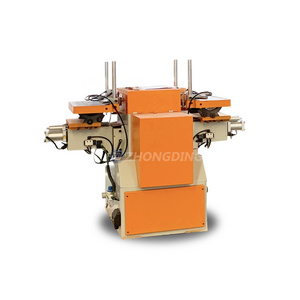

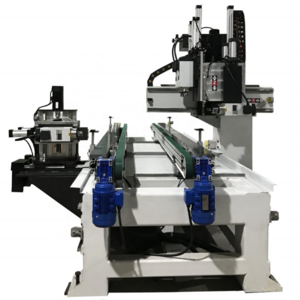

2300 2 Head Woodworking Door Lock Hole Chain Mortising And Drilling Machine

The processing material of this equipment is wooden door, and it is a special equipment for milling grooves, drilling holes and drilling holes on wooden door panels according to the processing drawings. This equipment is suitable for small batch production of split locks, magnetic card locks, anti-theft locks, conjoined locks and other lock-type wooden doors.

|

PARAMETERS of

Dour lock mortising machine

|

|

|

|

|||

|

Max.drilling length

|

2500mm

|

Max.drilling height

|

80mm

|

|||

|

Maximum groove depth

|

130mm

|

Maximum groove length

|

2000mm

|

|||

|

Spindle speed

|

18000r/min

|

Number of knife

|

4 pcs

|

|||

|

Working pressure

|

6-8kg

|

Total power

|

28.5kw

|

|||

Detailed Images

Control panel

Work table

Cylinder

Circuit board

Similar Productions

FAQ

How to buy

1. Contact PINLIANG sales and provide your requirements to get best solutions

2. Order confirmed, get invoice, contract from PINLIANG.

3. Normally, production started against TT by 30% deposit.

4. After one week, PINLIANG sales inform you production state and delivery date.

5. Order finished, PINLIANG sales send you photos, videos and spare parts for confirmation.

6. Book shipping order, delivery the machine to your port.

2. Order confirmed, get invoice, contract from PINLIANG.

3. Normally, production started against TT by 30% deposit.

4. After one week, PINLIANG sales inform you production state and delivery date.

5. Order finished, PINLIANG sales send you photos, videos and spare parts for confirmation.

6. Book shipping order, delivery the machine to your port.

How to do if I can not operate

When you get the machine, if you have operation problem, we will make video meeting to teach you. If video teaching can not solve,

our engineers will go to your place, and all charges paid by customer's side.

How to get spare part after warranty

After many years using, service will be important. We will always responsible for PINLIANG machines, including find problems, send

spare parts, and teach you to replace the parts.

our engineers will go to your place, and all charges paid by customer's side.

How to get spare part after warranty

After many years using, service will be important. We will always responsible for PINLIANG machines, including find problems, send

spare parts, and teach you to replace the parts.

Service contacting

Before buying, choose suitable model contact 008618934373658 (whtsAp). After buying, technical supporting contact 008618934373631(whtsAp)

Production Process

We use imported CNC machine to process parts. The main steel parts of all machines are formed by laser cutting. Through the careful design of engineers, the structure of the machine is stable and durable.

Each machine is tested and inspected for a long time before leaving our factory to ensure that each machine is qualified and excellent in quality.

Our Company

PINLIANG(Foshan pinruiliang machinery Co.,Ltd) is located in Shunde, Guangdong. We have a professional factory of more than 4000 square meters and have been committed to designing, producing and selling high-quality woodworking machinery.

PINLIANG have engineers with more than 20 years of working experience and can provide customers with whole plant solutions for solid wood machinery and panel machinery.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Packing & Delivery

When machine are finished, we will provide plywood packaging or regular packaging as needed.

PINLIANG have a professional loading team. The pre-planning of container loading makes full use of the container space. After machine are loaded into the container, it will be firmly fixed to ensure that all machines are safe and stable during transportation. (Plywood packaging

is firmer but requires additional costs

)

Hot Searches