- Product Details

- {{item.text}}

Quick Details

-

Output Voltage (V):

-

5kv

-

Output Frequency:

-

5kw

-

Pre-sales project design:

-

Household wind power

-

power:

-

5KW

-

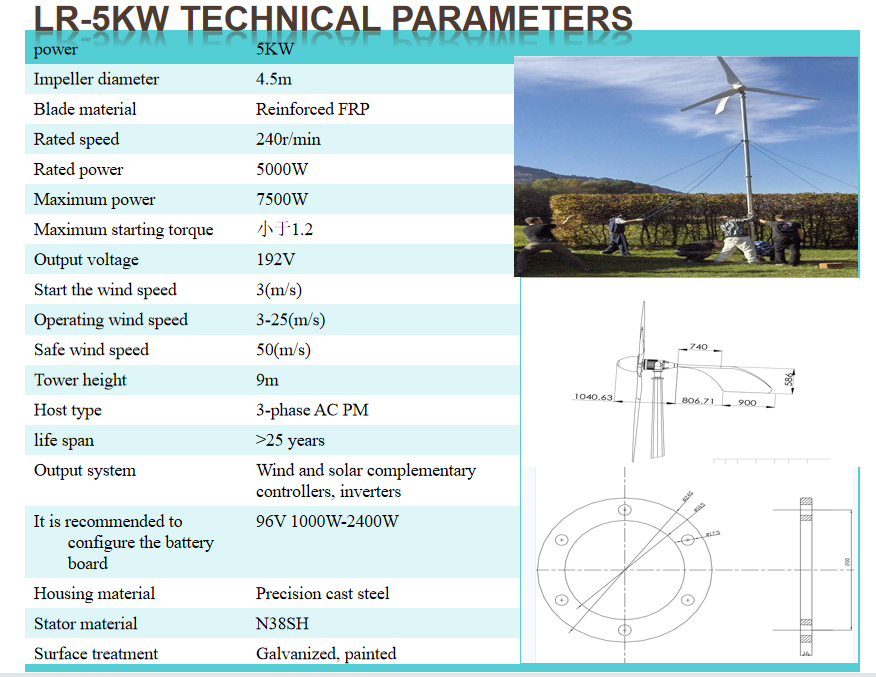

Impeller diameter:

-

4.5m

-

Blade material:

-

Reinforced FRP

-

Rated speed:

-

240r/min

-

Rated power:

-

5000W

-

Maximum power:

-

7500W

-

Maximum starting torque:

-

Less than 1.2

-

Output voltage:

-

192V

-

Start the wind speed:

-

3(m/s)

-

Operating wind speed:

-

3-25(m/s)

Quick Details

-

Place of Origin:

-

jiangsu

-

Brand Name:

-

luheenergy

-

Model Number:

-

5KW

-

Output Voltage (V):

-

5kv

-

Output Frequency:

-

5kw

-

Pre-sales project design:

-

Household wind power

-

power:

-

5KW

-

Impeller diameter:

-

4.5m

-

Blade material:

-

Reinforced FRP

-

Rated speed:

-

240r/min

-

Rated power:

-

5000W

-

Maximum power:

-

7500W

-

Maximum starting torque:

-

Less than 1.2

-

Output voltage:

-

192V

-

Start the wind speed:

-

3(m/s)

-

Operating wind speed:

-

3-25(m/s)

Product Display

Wind power

Conventional small horizontal axis wind turbines (with tail protection),

When the wind speed is high, it is necessary to rely on tail folding or yaw to reduce the speed of the wind turbine and play a role in regulating and protecting the wind turbine. The usual tail working direction is left and right folding tail protection, when the wind speed is high, affected by the tail rod length and tail area and tail rod angle, there will be slow response, and after the speed of the folding tail protection generator is reduced, it will produce a slow return phenomenon, similar problems directly lead to a greatly reduced efficiency of the wind turbine, unable to maximize the value of the wind turbine to the use of wind energy. At the same time, the perennial consistent tail folding action of the tail rod is bound to greatly reduce the mechanical stability of the tail rod, and damage phenomena such as tail rod breaking will occur after a certain period of time, causing machine failure and even danger. Due to structural reasons, the traditional fold-tail horizontal shaft wind turbine cannot be completely sealed, unable to overcome water seepage, prevent sand and dust erosion, and greatly reduce the safety protection level. In the practical application of traditional folding tail horizontal shaft wind turbine, the tail rudder shaft and shaft sleeve will have different degrees of wear, affecting the working point of the tail rudder, and the important thing will make the tail rudder lose its function, burn the generator in high winds, and cause serious damage.

1. The wind wheel structure is simple, the wheel hub adopts a mature fixed pulp structure, no complex moving mechanical devices, maintenance-free, and the failure rate is extremely low.

2. All parts are made of conventional national standard parts, and accessories can be bought all over the world.

3. Three-phase transmission slip ring is used for conduction, and there is no torsion cable phenomenon.

4. The vertical shaft of the rotary body has no rigid drive mechanism, only uses conventional bearings, this structure can easily dissolve the jitter and vibration caused by unstable airflow, which is conducive to improving the life of the wind turbine.

Specification

Conventional small horizontal axis wind turbines (with tail protection),

When the wind speed is high, it is necessary to rely on tail folding or yaw to reduce the speed of the wind turbine and play a role in regulating and protecting the wind turbine. The usual tail working direction is left and right folding tail protection, when the wind speed is high, affected by the tail rod length and tail area and tail rod angle, there will be slow response, and after the speed of the folding tail protection generator is reduced, it will produce a slow return phenomenon, similar problems directly lead to a greatly reduced efficiency of the wind turbine, unable to maximize the value of the wind turbine to the use of wind energy. At the same time, the perennial consistent tail folding action of the tail rod is bound to greatly reduce the mechanical stability of the tail rod, and damage phenomena such as tail rod breaking will occur after a certain period of time, causing machine failure and even danger. Due to structural reasons, the traditional fold-tail horizontal shaft wind turbine cannot be completely sealed, unable to overcome water seepage, prevent sand and dust erosion, and greatly reduce the safety protection level. In the practical application of traditional folding tail horizontal shaft wind turbine, the tail rudder shaft and shaft sleeve will have different degrees of wear, affecting the working point of the tail rudder, and the important thing will make the tail rudder lose its function, burn the generator in high winds, and cause serious damage.

Main Products

Hot Searches