- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

BESTICE

-

Weight:

-

1800 KG, 1800 kgs

-

Dimension(L*W*H):

-

2350 * 1450 * 1500mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Working Width:

-

1300/1600mm

-

Max. Rewinding Diameter:

-

150mm for 4 shafts; 300mm for 2 shafts

-

Paper Core inside diameter:

-

3'' (76.2mm)

-

Min. Cutting Width:

-

12mm

-

Slitting System:

-

Razor Blade (Air source knife optional)

-

Blade:

-

0.2mm x 22mm x 60mm

-

Speed:

-

260m/min

-

Dimension:

-

2350*1450*1500mm

Quick Details

-

Voltage:

-

380V/50HZ

-

Power:

-

4kw

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

BESTICE

-

Weight:

-

1800 KG, 1800 kgs

-

Dimension(L*W*H):

-

2350 * 1450 * 1500mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Working Width:

-

1300/1600mm

-

Max. Rewinding Diameter:

-

150mm for 4 shafts; 300mm for 2 shafts

-

Paper Core inside diameter:

-

3'' (76.2mm)

-

Min. Cutting Width:

-

12mm

-

Slitting System:

-

Razor Blade (Air source knife optional)

-

Blade:

-

0.2mm x 22mm x 60mm

-

Speed:

-

260m/min

-

Dimension:

-

2350*1450*1500mm

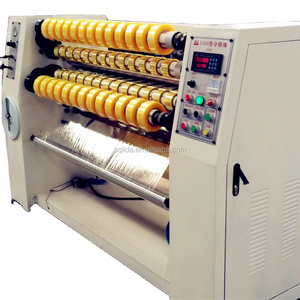

Product Overview

High Speed 1300/1600mm BOPP Gum Tape Automatic Slitting Rewinding Machine

It is a professional BOPP tape slitting rewinding machine and one whole set include 4 sets machine: one set bopp tape slitting rewinding machine, one set paper core loading and unloading machine, one set paper core cutting machine and one set mini type rewinding machine.

Features:

1. Suitable for slitting rewinding the BOPP gum tape.

2. The machine adopt central control for easy operate.

3. Three section meter counter to make sure the accurate of the rewinding length.

4. Auto shaft exchange: once two shafts rewinding finished then another two shafts auto exchange which can improve work efficiency.

5. Arc stretching roller can eliminate the tape wrinkles and flat the material for feeding well.

6. Cycloid big wasted rewinding about 3 jumbo roll no need discharge the waste.

7. None stop rewinding shaft load and unload system for high efficiency production.

2. The machine adopt central control for easy operate.

3. Three section meter counter to make sure the accurate of the rewinding length.

4. Auto shaft exchange: once two shafts rewinding finished then another two shafts auto exchange which can improve work efficiency.

5. Arc stretching roller can eliminate the tape wrinkles and flat the material for feeding well.

6. Cycloid big wasted rewinding about 3 jumbo roll no need discharge the waste.

7. None stop rewinding shaft load and unload system for high efficiency production.

|

Working width

|

1300mm

|

1600mm

|

|

Rewinding length

|

500/1000m

|

500/1000m

|

|

Unwinding diameter

|

600/800mm

|

600/800mm

|

|

Paper core diameter

|

3'' (76.2mm)

|

3'' (76.2mm)

|

|

Cutting Width

|

12-1300mm

|

12-1600mm

|

|

Slitting knife

|

Industrial Razor Blade

|

Industrial Razor Blade

|

|

Speed

|

260m/min

|

260m/min

|

|

Electricty

|

380V, 50HZ ,3Phase or custom

|

380V, 50HZ ,3Phase or custom

|

|

Dimension

|

2750mm * 1250mm * 1500mm

|

3100mm*1250mm*1500mm

|

Paper Core Loading and Unloading Machine

Used for loading and unloading finished products of adhesive tape and paper core.

Recommend Products

Certifications

Product packaging

FAQ

Q1: Can I custom this machine?

A1: Yes, as a professional manufacturer, we can supply OEM service, customized machine as your request.

Q2: Does your packing safe?

A2: Sure. For LCL, we pack machine into export standard wooden case which is suitable for long time ocean shipping. For FCL, we load naked machines into container and then fix them by steel wire, very safe.

Q3: What is your payment terms?

A3: 30% T/T as deposit and 70% T/T payment before shipment, or 100% irrevocable L/C at sight.

Q4: What is your delivery?

A4: About 20-45 wording days after deposit.

Q5: Can I get guarantee?

A5: Yes, we supply 1 year guarantee for all of our machines.

A1: Yes, as a professional manufacturer, we can supply OEM service, customized machine as your request.

Q2: Does your packing safe?

A2: Sure. For LCL, we pack machine into export standard wooden case which is suitable for long time ocean shipping. For FCL, we load naked machines into container and then fix them by steel wire, very safe.

Q3: What is your payment terms?

A3: 30% T/T as deposit and 70% T/T payment before shipment, or 100% irrevocable L/C at sight.

Q4: What is your delivery?

A4: About 20-45 wording days after deposit.

Q5: Can I get guarantee?

A5: Yes, we supply 1 year guarantee for all of our machines.

Customer Photos

Hot Searches