Electrostatic Powder Coating Machine is a dry finishing process, using finely ground particles of pigment and resin that are generally electrostatically charged and sprayed onto electrically grounded parts. The charged powder particles adhere to the parts and are held there until melted and fused into a smooth coating in a curing oven. Before coating, the parts to be coated are first pretreated similarly to conventional liquid coated parts. The pretreatment process is normally conducted in series with the coating and curing operatios.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Power:

-

50kw

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

350

-

After-sales Service Provided:

-

Video Technical Support

-

Spraying Guns:

-

Manual Electrostatic Spraying Guns

-

Coating Technology:

-

Manual Electrostatic Coating

-

Advantage:

-

High Production Efficiency

-

Local Service Location:

-

Viet Nam

Quick Details

-

Machine Type:

-

automatic machine line, Spray Booths, Painting Equipment, Pre-treatment Equipment, Drying Oven, Curing oven, Coating Equipment

-

Place of Origin:

-

China

-

Brand Name:

-

jrx

-

Voltage:

-

380v

-

Power:

-

50kw

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

350

-

After-sales Service Provided:

-

Video Technical Support

-

Spraying Guns:

-

Manual Electrostatic Spraying Guns

-

Coating Technology:

-

Manual Electrostatic Coating

-

Advantage:

-

High Production Efficiency

-

Local Service Location:

-

Viet Nam

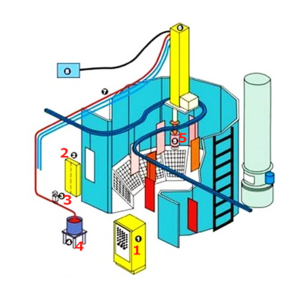

Production Introduction

|

Item

|

Specification

|

|

External Size

|

2340*3080*2000mm

|

|

Internal Size

|

2300*3000*1960mm

|

|

Wall Panel

|

2.0 mm cold steel wall panels. Usually the color is white, can be customized upon your request.

|

|

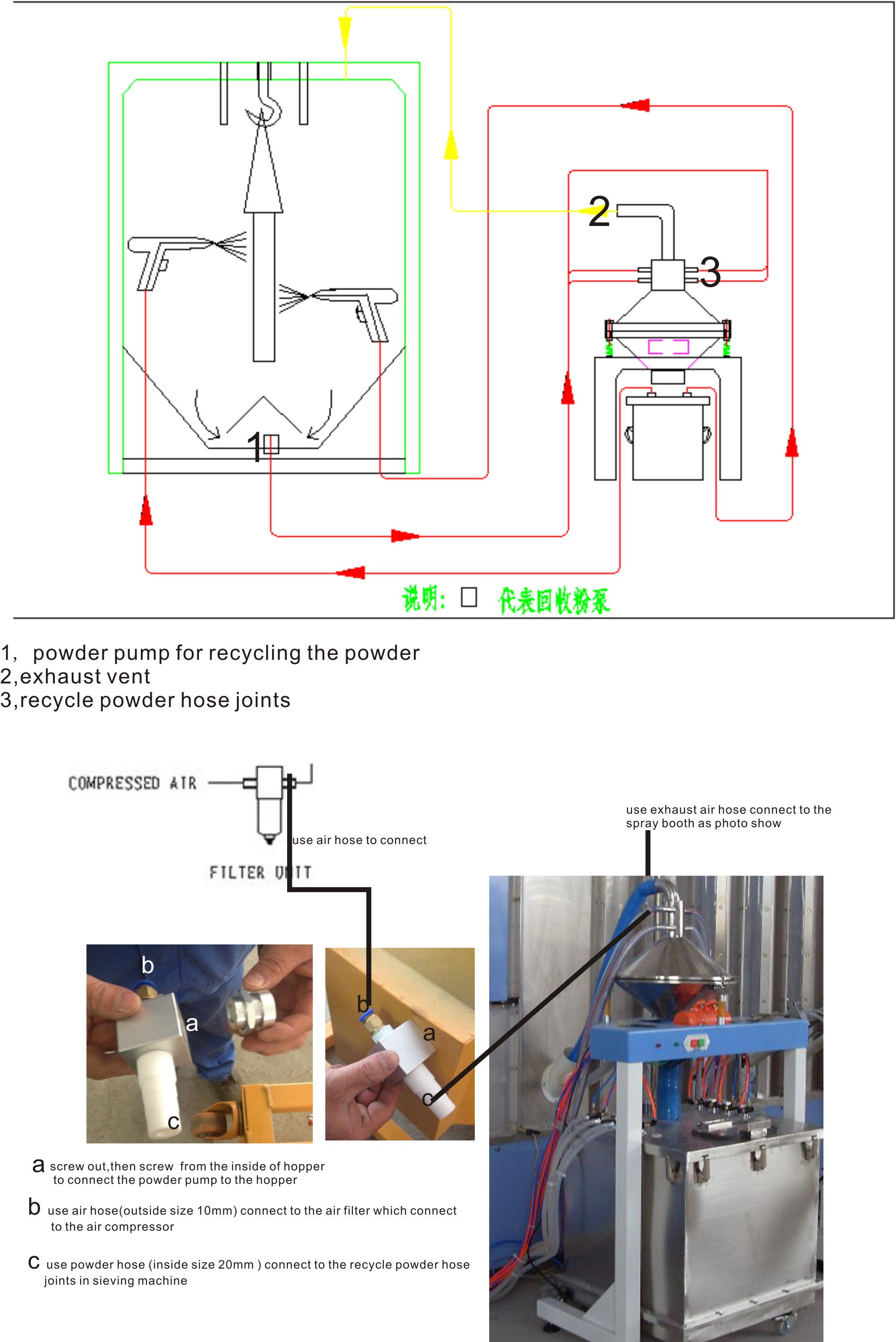

Powder Recovery System

|

The powder recovery system including filters, air tank, solenoid valve and powder tank.

|

|

Air Circulation System

|

1 Unit of 1.1 kw CF-11 air circulation fan, supply power for the air go through the filters. Air flow 1440-2250 m³/h

|

|

Control System

|

The control box including power on/off switch, fan start/off switch, E-stop switch etc.

|

|

Color

|

Usually the color is white, color can be customized

|

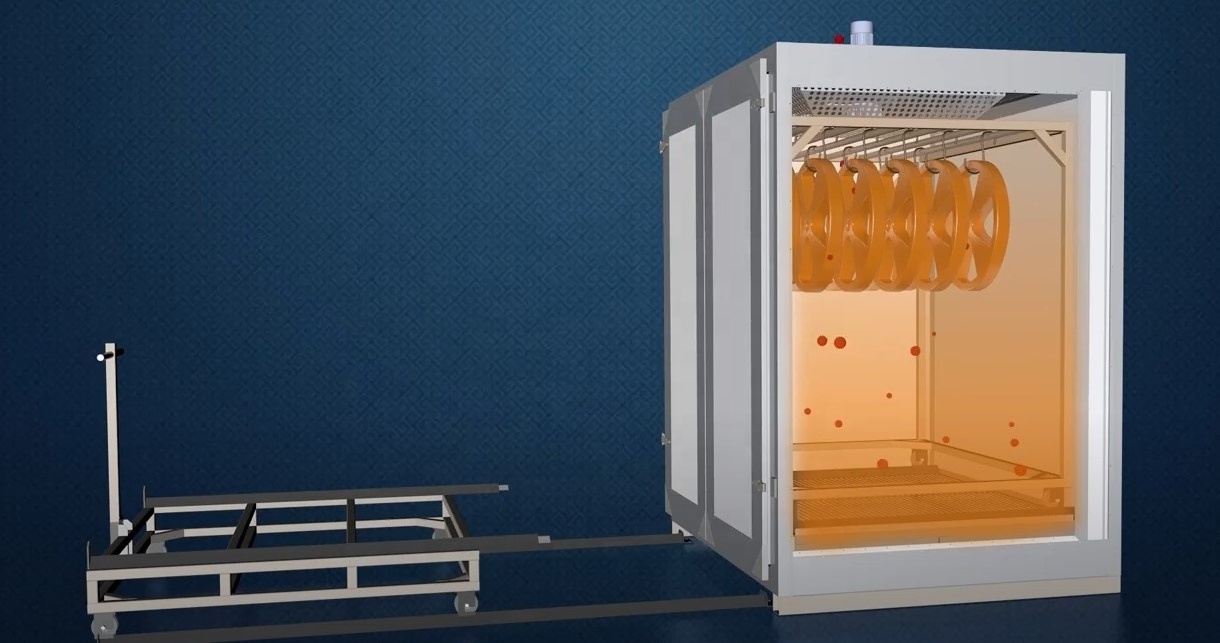

Baking oven booth

1) powder coating oven Compared with other powder oven, the life can be as long as 8-10 years or even longer.

2) The air inside the curing oven is clean to ensure the quality of the baking.

3) The drying oven is stable, ensuring that there are no

quality problems that will affect your spraying operation.

quality problems that will affect your spraying operation.

4) Hot air circulation ensures that the temperature error inside the powder coat oven is small, thus ensuring no color difference.

Powder sieving machine

1. automatic type recycling screen,it is used in continuous production, can significantly improve the efficiency

2. simpleoperation, low energy consumption,and strong sieving ability.

3. small volume, low noise and easy to change the filter screen.

4.screen diameter, 450mm, mesh number, 80-120, optional. 5. power supply, 220v/50Hz, 100W.

production Usage

Product packaging

1.Delivery time:

Within 15 working days after receiving deposit.

2.Package:

We use standard ecport packing in 20GP or 40GP

We will add stretchy film for the whole machine and spare parts for delicate protaction.

3.Guarantee:

The machine is guaranteed for 24 months.

If the machine has something problem in 24 months,you will get sprae part for free.

More than 24 months,you will get the cost price for accessories.

4.Techinical support:

Technical support by phone,email,wecaht,whatsapp and slype,24 hours online.

Engineer available to service macinery overseas.

5.After sales services:

Our machine is installed and tested well before delivery.

You can operate the machine immediately after receiving machine.

Within 15 working days after receiving deposit.

2.Package:

We use standard ecport packing in 20GP or 40GP

We will add stretchy film for the whole machine and spare parts for delicate protaction.

3.Guarantee:

The machine is guaranteed for 24 months.

If the machine has something problem in 24 months,you will get sprae part for free.

More than 24 months,you will get the cost price for accessories.

4.Techinical support:

Technical support by phone,email,wecaht,whatsapp and slype,24 hours online.

Engineer available to service macinery overseas.

5.After sales services:

Our machine is installed and tested well before delivery.

You can operate the machine immediately after receiving machine.

Our Company

We are QINGDAO JIERUIXIN MACHINERY AND TECHNOLOGY CO.,LTD. which company is mainly working on paper coating machine, paper making machine and related technology. Through more than 20 years effort, Besides the machine self, we have our own chemist and prefer to supply chemical, formulation, technology and other suggestion to customers. Then our formulation will match our machines, and get the best quality paper for them. Now Our company had been one of the famous paper coating machine manufacturer in China and our coating machine and technology had been exported to Egypt, Mexico, Australia, India and etc.

Our Services ( We can provide turnkey works)

1.Reasonable suggestions for selection of equipment.

2.Provide detailed description and assembly drawing to make you more aware of the device ability to work.

3.Engineers on site equipment installation and commissioning.

4.Provide training for your employees.

5.Professional technical guidance and technical support during your production, make sure the device's work properly

and production.

and production.

6.Equipment upgrade and remould.

7.We will testing installation machine in the factory workshop , to ensure safety and quality.

8.Supply chemical ,formulation ,technology and other suggestion to customers.

QINGDAO JIERUIXIN MACHINERY AND TECHNOLOGY CO.,LTD. the real person hood, steadfast work management concept, we warmly welcome all friends to visit.

Hot Searches