- Product Details

- {{item.text}}

Quick Details

-

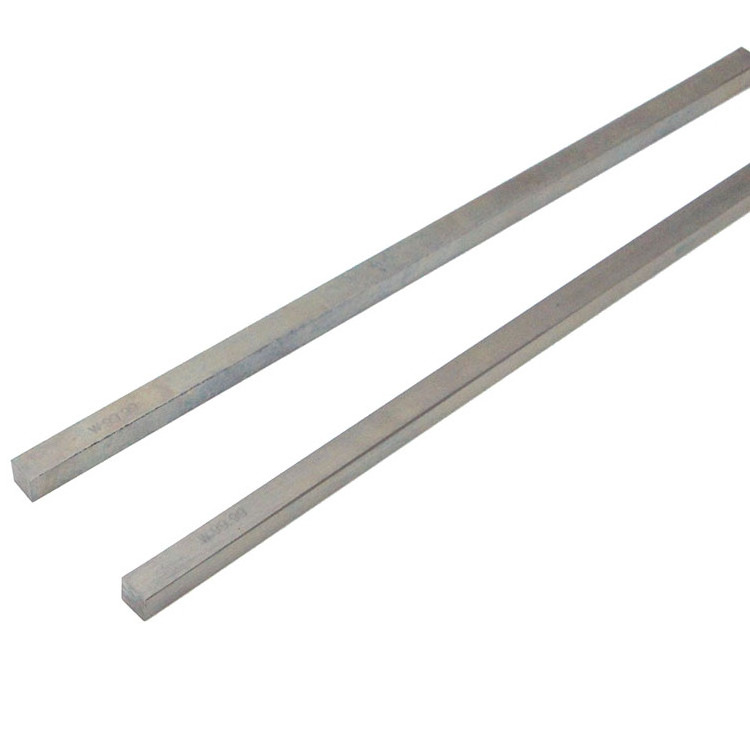

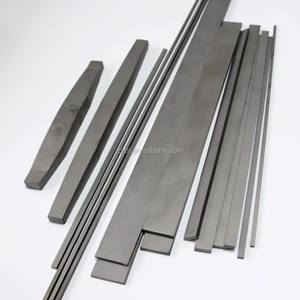

Product name:

-

silver alloy bar pure tungsten bar

-

Long Size:

-

330 mm

-

Weight:

-

35 KG/box

-

Application:

-

Aerospace

-

Size:

-

12*12*330mm

-

Surface:

-

Ground/Unground

-

Type:

-

pure tungsten bar

-

Grade:

-

W-1

-

Name:

-

99.98% strip

-

Packing:

-

foam and iron boxs

Quick Details

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

DINGLI

-

Model Number:

-

12A*12B*330L

-

Product name:

-

silver alloy bar pure tungsten bar

-

Long Size:

-

330 mm

-

Weight:

-

35 KG/box

-

Application:

-

Aerospace

-

Size:

-

12*12*330mm

-

Surface:

-

Ground/Unground

-

Type:

-

pure tungsten bar

-

Grade:

-

W-1

-

Name:

-

99.98% strip

-

Packing:

-

foam and iron boxs

Product Description

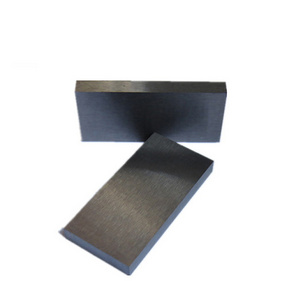

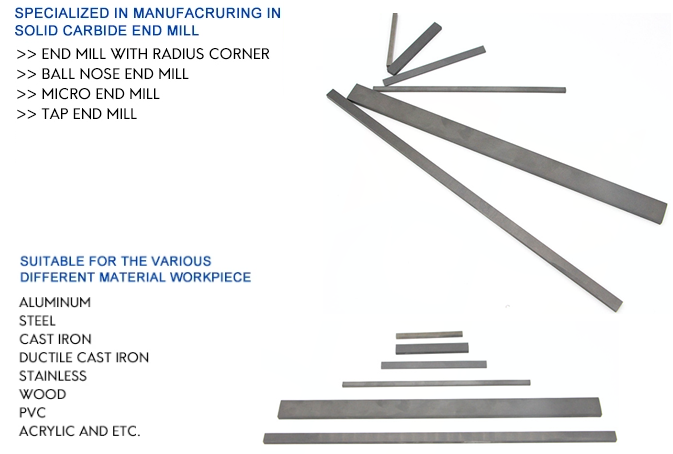

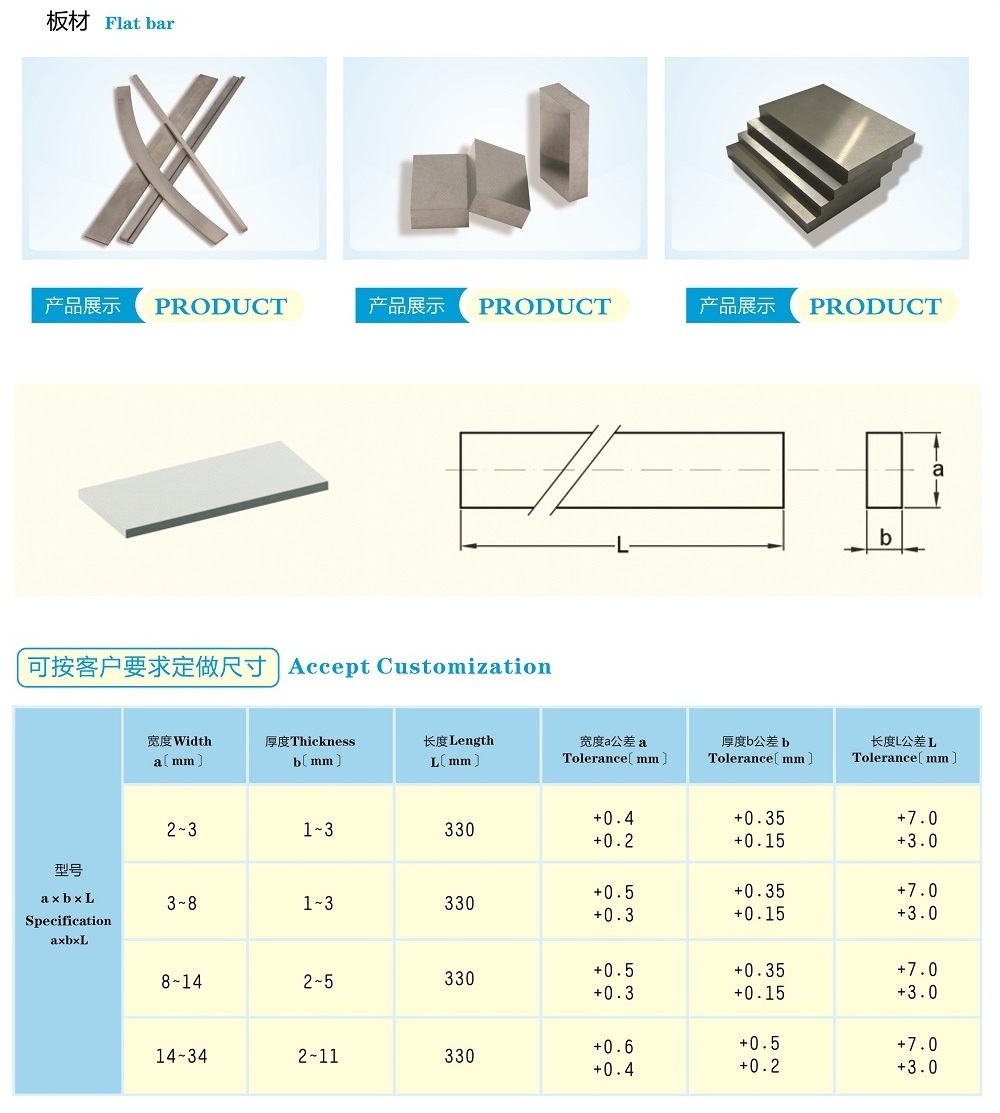

SPEC

-

Other Types:

|

Material

|

tungsten carbide

|

|

Chemical Composition

|

WC≥ 85.0%

|

|

Hardness (HV)

|

1475~1675

|

|

Compressive Strength (N/mm2)

|

5200

|

|

Transverse-rupture strength (N/mm2)

|

3300

|

|

Frature Toughness

|

10.0

|

-

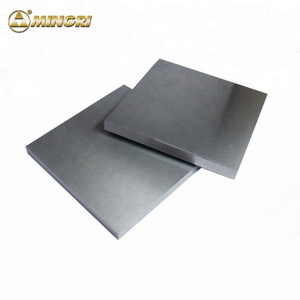

Tungsten Cemented Carbide Grade:

|

Grade

|

ISO Code

|

Chemical Component

(%)

|

|

|

Grain size

µm

|

Physial Mechanical Properties

(≥)

|

|

|

||||

|

|

|

WC

|

Co

|

Others

|

|

Density g/cm

3

|

Hardness (HRA)

|

T.R.S N/mm

2

|

||||

|

D10UF

|

K05-K15

|

93

|

6

|

1

|

0.6

|

14.80

|

93.0

|

2600

|

||||

|

D30UF

|

K20-K30

|

89

|

10

|

1

|

0.6

|

14.50

|

92.0

|

3800

|

||||

|

D30SF

|

K20-K30

|

89

|

10

|

1

|

0.5

|

14.40

|

92.5

|

4000

|

||||

|

D40SF

|

K40

|

87

|

12

|

1

|

0.4

|

14.15

|

92.5

|

4200

|

||||

|

DB10X

|

K20-K30

|

89

|

10

|

1

|

0.6

|

14.50

|

91.5

|

3800

|

||||

|

DP12X

|

K30-K40

|

87

|

12

|

1

|

0.6

|

14.15

|

91.0

|

3300

|

||||

|

DP13X

|

K40

|

87

|

12

|

1

|

1.0

|

14.10

|

90.0

|

3800

|

||||

|

YG6

|

K05-K10

|

94

|

6

|

0

|

1.2

|

14.80

|

91.0

|

2600

|

||||

|

YG6X

|

K10

|

94

|

6

|

0

|

1.0

|

14.80

|

92.0

|

2500

|

||||

|

YG8

|

K20-K30

|

92

|

8

|

0

|

1.2

|

14.70

|

90.0

|

2800

|

||||

|

YG10X

|

K30-K40

|

89

|

10

|

1

|

0.8

|

14.50

|

91.0

|

3500

|

||||

|

YG15

|

K40

|

85

|

15

|

0

|

1.2

|

13.95

|

87.5

|

4500

|

||||

|

D20UF

|

K20-K30

|

91

|

8

|

1

|

0.6

|

14.6

|

92.5

|

3000

|

||||

|

YG25

|

--

|

75

|

25

|

0

|

1.2

|

13.15

|

82.5

|

4800

|

||||

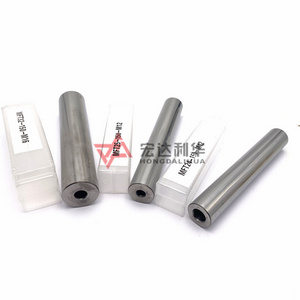

Related Products

Why Choose Us

Certifications

Company Introduction

Established in 2011,

Zigong Dingli Alloy Material Co. Ltd

currently locates in the famous production base of cemented tungsten carbide: Zigong city, Sichuan province. The factory always adheres to the “integrity-based, quality first and technology innovation” operating principles of market development. Because of the factory’s well-deserved reputation and the products’ high quality, Dingli not only gains the orderly and efficient development opportunity, but also the stable domestic and foreign sales market. In addition, Dingli has a well trained, strongly united and highly professional service team which mainly works on the manufacture of tungsten carbide and molybdenum products.

Through the dedicated efforts over eight years, the factory has accomplished dramatic breakthroughs on many products, especially on rods, bars and end mills, reaching an advanced level among coteries and possessing a few patents. As for the future’s plan, Dingli is going to increase the investment on production equipment and promote the training of professional skills on workers.

Besides, Dingli will also listen to all kinds of comments of domestic and foreign customers and provide them with the best products and first-rate service, making great contributions to the progress of cemented tungsten carbide industry. Dingli is looking forward to doing business with you because there is no doubt that cooperation leads to win-win situations.

Packing & Shipping

FAQ

Q1:How long is your delivery period?

A:It depends on specific conditions. However, it would be 10 to 15 days on average.

Q2:Do you offer samples?

A:Yes, we do offer samples. However, buyers need to pay for the freight charge. In addition, whether samples are free or not depends on the quantity you buy.

Q3:How do you pack the products?

A:In general, we use wood, plastic or carton boxes. We also put some soft materials inside to prevent possible damage on products.

Q4:How much advance payment do I need to make?

A:If the products you buy are in stock, you need to make full payment; if the products are out of stock, you need to make about 50 percent of full payment and then we will start the production process. However, you still need to pay the rest of charges before we deliver the products.

Q5:What kinds of payment do you accept?

A:In addition to the patterns of payment shown above, you can discuss with us about in which way you would like to pay.

Q6:Where are you? Can I visit you?

A:Sure,welcome to you visit our factory at any time.

Q7:What kinds of payment do you accept?

A:In addition to the patterns of payment shown above, you can discuss with us about in which way you would like to pay.

Hot Searches