- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v/480v/260v

-

Dimension(L*W*H):

-

10*2*2.4m

-

Power (kW):

-

55

-

Weight:

-

10t

-

Screw Speed (rpm):

-

30 - 60 rpm

-

Name:

-

Plastic Recycling Granulator Machine

-

Application:

-

Waste Plastic Recycling

-

Screw Diameter:

-

105mm-200mm

-

Main Motor Power:

-

7.5~55KW

-

SCREW MATERIAL:

-

38CrMoAl

-

Plastic Type:

-

PP PE ABS PA PS

-

Output:

-

200-600kg/h

-

Max. Capacity:

-

200kg/h-600kg/h

-

Power:

-

30kw

Quick Details

-

Output (kg/h):

-

120 - 150 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

MC

-

Voltage:

-

380v/480v/260v

-

Dimension(L*W*H):

-

10*2*2.4m

-

Power (kW):

-

55

-

Weight:

-

10t

-

Screw Speed (rpm):

-

30 - 60 rpm

-

Name:

-

Plastic Recycling Granulator Machine

-

Application:

-

Waste Plastic Recycling

-

Screw Diameter:

-

105mm-200mm

-

Main Motor Power:

-

7.5~55KW

-

SCREW MATERIAL:

-

38CrMoAl

-

Plastic Type:

-

PP PE ABS PA PS

-

Output:

-

200-600kg/h

-

Max. Capacity:

-

200kg/h-600kg/h

-

Power:

-

30kw

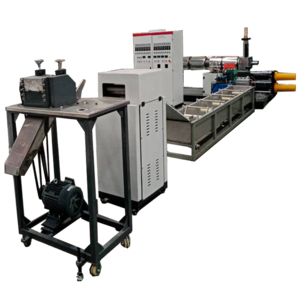

The main machine of plastic granulator is extruder, which is composed of extrusion system, transmission system and heating and cooling system.Extrusion system: the extrusion system includes screw, barrel, hopper, head and mold. The plastic is plasticized into a uniform melt through the extrusion system.Transmission system: the function of the transmission system is to drive the screw, to provide the screw in the extrusion process, the required speed, usually by the motor, reducer and bearing.Heating and cooling device: heating and cooling are the conditions for plastic extrusion process.

Preheating device of plastic granulator:

For the insulating layer, especially the thin layer insulation, the existence of the pores cannot be allowed, and the core can remove the moisture and oil on the surface by preheating before high temperature. For sheath extrusion, its main function is to dry the core to prevent the possibility of voids in the jacket due to moisture (or moisture surrounding the cushion). Preheating also prevents the internal pressure of the plastic from being quenched during extrusion.

Plastic granulator cooling device:

After the formed plastic extrusion layer leaves the machine head, it should be cooled and shaped immediately, otherwise it will be deformed under the action of gravity. The cooling method is usually cooled by water and divided into quenching and slow cooling depending on the water temperature.

1. The main and auxiliary machine screw barrels are made of imported high-strength carbon structural steel, which is durable.

2. Conical screw barrel is used to speed up the feeding speed and greatly improve the output and quality.

3. The main and auxiliary machines are used for production, the heating temperature is stable, the molecular structure of the material is effectively improved, the gas permeability is enhanced, and the particle quality is obviously improved.

4. The unit is mainly composed of crushing dry cleaning machine, extruder and automatic traction granulator. Automatic feeding, automatic temperature control, automatic dust removal, impurity removal, automatic filter change, no pollution in the production process, this plastic granulator is a twin-screw fifth-generation waste plastic granulator, equipped with computer-type automatic control The cabinet is easy to operate and stable in performance.

Applicable plastic:

PE/LDPE film, PP woven bag/ton bag/space bag, municipal solid waste film, paper mill material, HDPE/PP/ABS and other hard materials, PVC materials, etc.

Finished products after processing waste plastics:

Waste plastic recycling process:

The recycling process of waste plastics is recycling - crushing - Cleaning - drying - granulation - extrusion moulding (new products), while the granulation production line occupies a part of the plastic recycling process.

The packaging method is based on the size of the machine, small machines are packed in wood, and large machines are used in containers.

Our minimum order quantity is one machine and the delivery time is 30 days.

As long as you place an order, we will ship it to you as soon as possible.

Looking forward to working with you for your pleasure!

The company produces a variety of plastic machinery equipment, because of equipment models, functions and products more. In order to facilitate your use, you are welcome to inquire the specific situation. We will help you choose the model according to your purpose. (all our products can be customized)

Service Commitment Pre-sale Service:

Provide you with project design, process design, suitable for your machine and equipment purchase plan formulation, according to your special needs, design and manufacture products, training technical operators for you.

In-sales service:

Accompany you to complete the acceptance of the equipment, assist in drafting the construction plan and detailed process.

After-sale service:

1.We provide video support and technical guidance during installation.

2.We offer a one-year warranty and any warranty on the machine during the year can be guaranteed.