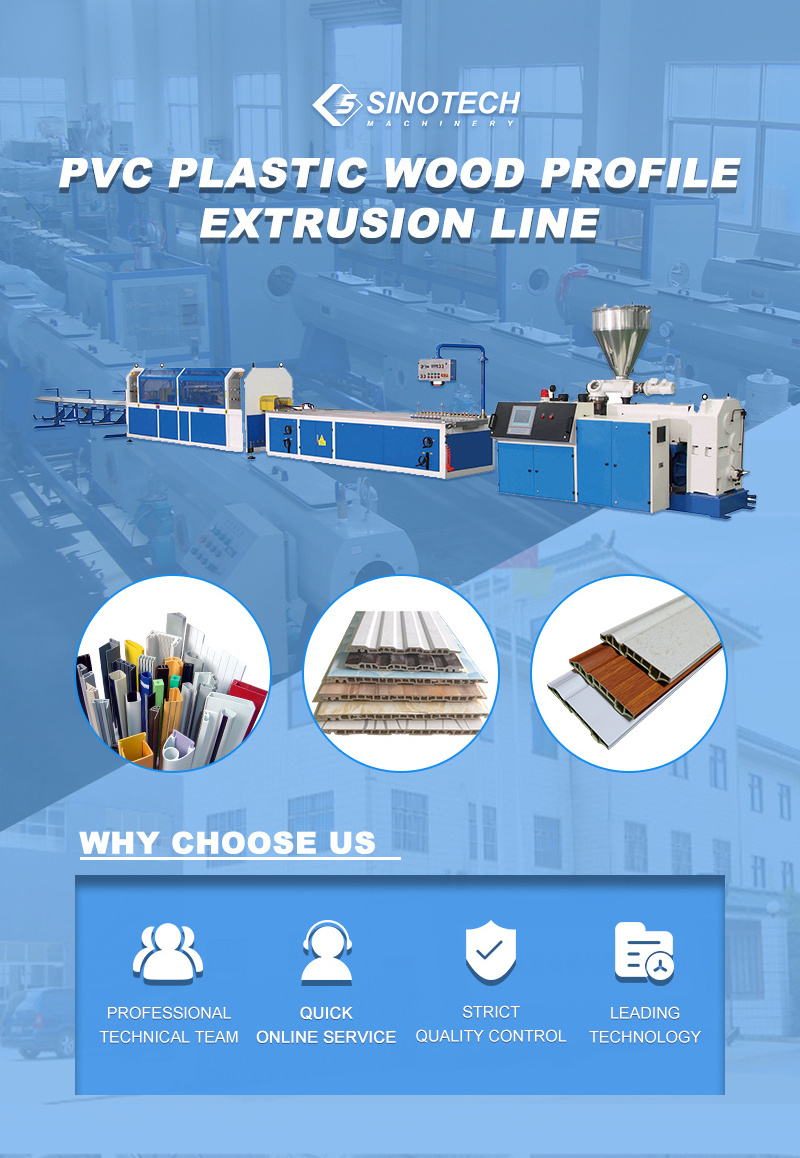

• World famous brand electrical component such as Siemens,Schneider, ABB etc;

• High torque gearbox with adopts NSK/SKF bearing;

• Siemens/WEG original motor achieved global after service; • Bimetallic screw and barrel;

• Intelligent PLC controlling system with human-friendly interface.