- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

≥ 99.7%

-

Voltage:

-

AC Three-Phase 380V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Bottlinglife

-

Dimension(L*W*H):

-

3000*1500*2500

-

Weight:

-

500 KG

-

Product name:

-

Bottlinglife

-

Function:

-

Filling Capping Labeling

-

Bottle type:

-

PET Plastic Bottle Glass Bottle

-

Feature:

-

Quick Changeover

-

Type:

-

Filling Mchine, Filling Machine

-

Capacity:

-

2000-30000bph

-

Keywords:

-

Fillng Line

-

Usage:

-

Filling Capping Labeling Packaging

-

Control:

-

PLC+ Touch Screen+Inverter

-

Material:

-

SUS304/316

Quick Details

-

Machinery Capacity:

-

4000BPH, 2000BPH

-

Packaging Material:

-

Plastic, Wood, Other

-

Filling Material:

-

Beer, Other, Milk, Water, Oil, Juice, Powder, jam, paste

-

Filling Accuracy:

-

≥ 99.7%

-

Voltage:

-

AC Three-Phase 380V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Bottlinglife

-

Dimension(L*W*H):

-

3000*1500*2500

-

Weight:

-

500 KG

-

Product name:

-

Bottlinglife

-

Function:

-

Filling Capping Labeling

-

Bottle type:

-

PET Plastic Bottle Glass Bottle

-

Feature:

-

Quick Changeover

-

Type:

-

Filling Mchine, Filling Machine

-

Capacity:

-

2000-30000bph

-

Keywords:

-

Fillng Line

-

Usage:

-

Filling Capping Labeling Packaging

-

Control:

-

PLC+ Touch Screen+Inverter

-

Material:

-

SUS304/316

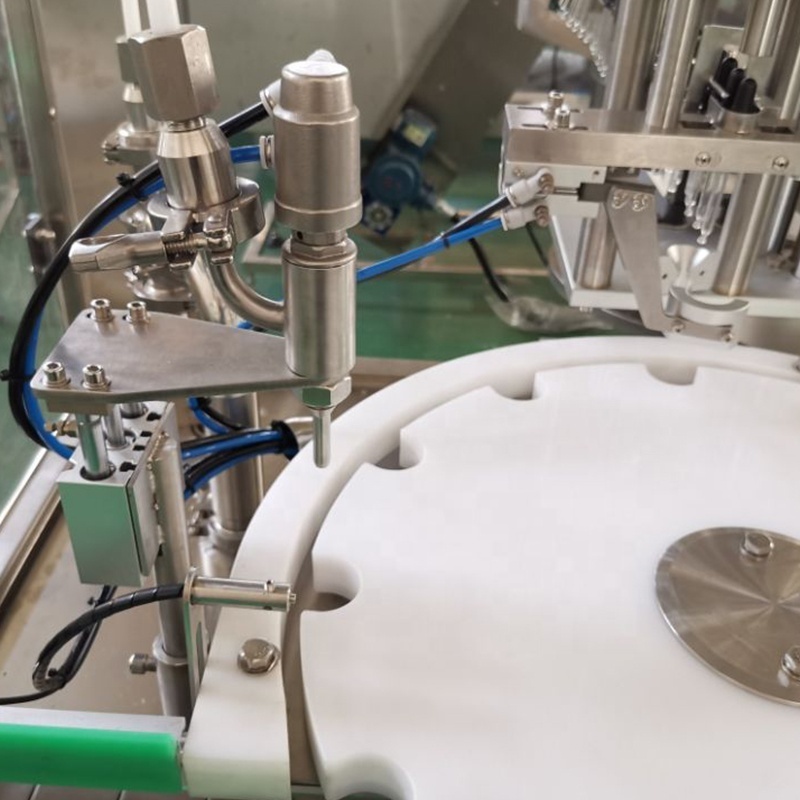

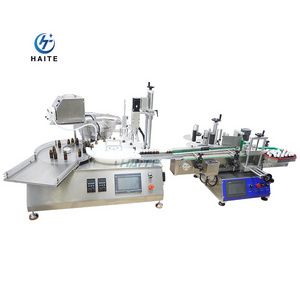

This Automatic vial bottle filling line is suitable for 10ml-100ml glass and plastic bottle,this machine is made up of high precision CAM indexing mechanism,positioning and filling of equal plate,pressure inner cap,screw outer cap. Motor torque capper with adjustable torque cap,volumetric pump orperistaltic pump filling ,touch screen control ,no bottle no filling,no cap no capping. With smooth transmission,accurate positioning and measurements simple operation and other advantages,the inner and outer caps are calibrated and algned with the autocratic mold,with high passing rate.according to the capacity.the sorters can customized for single track and double track feeding,to match the efficiency of the whole machine capacity.

|

Description

|

Tincture Oil Filling Capping Machine

|

|

Filling nozzles

|

1/2

|

|

Outside cap capping nozzle

|

1/2

|

|

Filling capacity

|

10ml-100ml

|

|

Filling speed

|

3000 b/Hr

|

|

Eligibility rate of inside tuck and outside tuck

|

=99%

|

|

Air pressure

|

0.6Mpa

|

|

Feature

|

1.Can fill up to 100 ml.

2.Meets GMP requirements and follows cGMP guidelines.

3.rotary filling design.

4.High-accuracy multi-head filling station.

5.Diving nozzles for optimized filling cycle.

6.Positive pick and place plugging station.

7.Positive pick and place cap placement and/or pre-tightening station. 8.Independent final cap torquing/crimping station with torque control.

|

Filling accuracy

expectation of

± 2% (for 0.5 ml to 5 ml fill volume)

± 1% (for 5ml to 15 ml fill volume)

± 0.5% (over 15 ml fill volume)

Filling Nozzle

Stainless steel 316L

Spring loaded ball check valve.

With re-enforce silicon hoses

(food Grade) for product transfer.

Custom attachment system for

BottlingLife equipment.

Final design adapted to the

product to be fill (To Be Confirm)

Filling Nozzle with

Shut Off System

Preventing dripping with viscous

& semi viscous products.

Stainless steel 316L.

Pneumatic activated plunger for

sealing the nozzle.

Quick disconnect air hose system

for wash down.

Dismantling of the nozzle with the

usage of any tools.

With re-enforce silicon hoses

(Food Grade) for product transfer.

Capping Station

(Screw Caps)

One (X1) transfer star wheel for

Capping station.

Tube Alignment with ‘’Funnel’’ Device

to properly introduce the pipette into

the bottle.

One (X1) final independent Magnetic

torque control.

Torque accuracy 0.2 Nm (± 2 in.-lb.)

across a range of 0.56 to 22.4 Nm

(5 – 100 in.-lb.)

Magnetic Torque adjustable tighten the cap to prevent any damage to the caps.

Installation Requirements

• 220 volts, 3 phases, 60 Hz, 15 amp or customize.

• Power consumption: 4.5 kw.

• Air regulator with filter with ¼’’ quick connect male with ½’’ NPT.

• Air at 100 PSI (6.9 bar).

• Air consumption 20 CFM (566 L/m).

• Instruction sticker.

Safety Feature

• Emergency stop push button switch install directly onto the panel control.

• Torque-limiting sensor on all motion system.

• Back up sensor at the exit conveyor that stops the machine in case of

accumulation Euroguard Safety Interlock System.

• 6 mm (¼’’) thick tempered glass barrier doors shield the machine perimeter.

• Doors are mounted on stainless steel tubing which also enclosed the electrical wirings.

• Safety interlocks are installed to ensure the safety of the operators before.

Control System

• Stainless steel panel control

• Stainless steel, tubular holding post with Twin axis swivel panel control.

• Emergency Stop on the control panel.

• (7’’) multi-color touch screen control

• HMI resolution

• Programmable feeder, conveyor speed, etc.

• For normal machine operation with alarm display.

• Possibility to have different language interfaces.

Quality Control of the equipment

System verification.

Safety feature verification.

Mechanical inspection

Safety feature verification.

Electrical inspection.

Pneumatic inspection.

Production tests

Runs for all bottle presentations.

Cleaning of the equipment

Ensuring correct parameters are all

recipes are set.

Observations recorded in Test

Summary.

Including the bottling rate

cleaning of the equipment

Complete cleaning of equipment,

inside and out.

Checks for physical damage.

Check for sharp edges.

Check for presence of variable

safety or hazard warning signs.

Preparation for shipping

All change parts collected and

accounted for before packaging.

Sensitive parts individually wrapped

and braced for transport.

Equipment properly braced for

transport.

Special preparations for overseas

packaging.

Q1.Where is it located the manufacturer?

A.We are located in shanghai china.

Q2.How long is the warranty?

A.The warranty is one year with easy damage part for free.

Q3.How long it would take to deliver if I decided to purchase?

A.Because all of our machine will be customized according to your bottles .SO theproduction time is about 30-40 days after get your bottle samples and deposit .?

Q4.How is the cost of power per day of the machine?

Q2.How long is the warranty?

A.The warranty is one year with easy damage part for free.

Q3.How long it would take to deliver if I decided to purchase?

A.Because all of our machine will be customized according to your bottles .SO theproduction time is about 30-40 days after get your bottle samples and deposit .?

Q4.How is the cost of power per day of the machine?

A.the machine power need about2kw-5kw

Q5.ln case of breakdown the parts are it easily findable and deliver quickly?

Q5.ln case of breakdown the parts are it easily findable and deliver quickly?

A.Yes.we will provide you one years warranty with any easy damage spare part forfree with free shipping .

Q6.What resources does your company offer in terms of set up and additionalsupport?

A.Our engineer is avaliable to set up machine and provide technical support for you.beside this .we provide manual book and video support

Q7.Can i send bottle and cap test ?how much would you need ?can you makea video of this ?

A.our machine is customized according to the bottle size and cap size .when machineis ready we will send you test video with your bottle and caps .bottle we need about100 for each size .cap we need 200 for each size.

Q8.What about spare parts?

A.We will send enough perishable spare parts for one year with the machine shippedtogether. We will offer spare parts within the warranty term.

Q9.How do i test the machine before shipment?

A.We will run the machine for 48 hours .and send you the test video .we can alsohave remote FAT.

Q10.Do you have certificates?

A.Yes.we have been certified .we can also provide IQ OQ documentation.

Q11.Do you have any reference?

A.We have reference programs in most countries. Suppose we get permission from acustomer who imports machines from us. In this case, we can give you their contactinformation and you can direct call them for a reference.

Q6.What resources does your company offer in terms of set up and additionalsupport?

A.Our engineer is avaliable to set up machine and provide technical support for you.beside this .we provide manual book and video support

Q7.Can i send bottle and cap test ?how much would you need ?can you makea video of this ?

A.our machine is customized according to the bottle size and cap size .when machineis ready we will send you test video with your bottle and caps .bottle we need about100 for each size .cap we need 200 for each size.

Q8.What about spare parts?

A.We will send enough perishable spare parts for one year with the machine shippedtogether. We will offer spare parts within the warranty term.

Q9.How do i test the machine before shipment?

A.We will run the machine for 48 hours .and send you the test video .we can alsohave remote FAT.

Q10.Do you have certificates?

A.Yes.we have been certified .we can also provide IQ OQ documentation.

Q11.Do you have any reference?

A.We have reference programs in most countries. Suppose we get permission from acustomer who imports machines from us. In this case, we can give you their contactinformation and you can direct call them for a reference.

Hot Searches