- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

6000

-

Keyword:

-

Square Pipe Making Machine

-

Function:

-

Stainless Steel Pipe Production Line

-

Pipe Shape:

-

Round/Square/Rectangle

-

Pipe application:

-

Decorative Tube

-

Round Pipe Diameter:

-

15.88-50.8 mm

-

Round Pipe Thickness:

-

0.2-2.0 mm

-

Square/Rectangular Pipe Size:

-

10*10-40*40/10*20-30*50 mm

-

Square/Rectangular Pipe Thickness:

-

0.3-2.0 mm

-

Operator:

-

1 Person Can Operate 2 Machines

-

Useful life:

-

More than 10 Years

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Machinery Test Report:

-

According To Actual Situation

-

Brand Name:

-

YXH Pipe Making Machinery

-

Weight (KG):

-

6000

-

Keyword:

-

Square Pipe Making Machine

-

Function:

-

Stainless Steel Pipe Production Line

-

Pipe Shape:

-

Round/Square/Rectangle

-

Pipe application:

-

Decorative Tube

-

Round Pipe Diameter:

-

15.88-50.8 mm

-

Round Pipe Thickness:

-

0.2-2.0 mm

-

Square/Rectangular Pipe Size:

-

10*10-40*40/10*20-30*50 mm

-

Square/Rectangular Pipe Thickness:

-

0.3-2.0 mm

-

Operator:

-

1 Person Can Operate 2 Machines

-

Useful life:

-

More than 10 Years

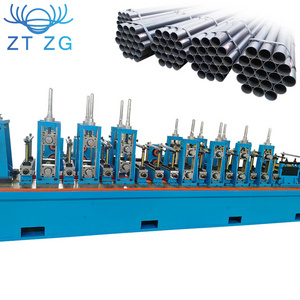

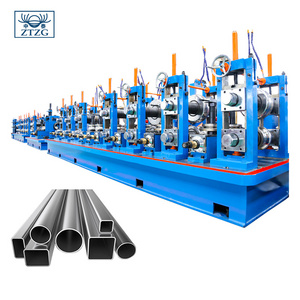

Stainless Steel Pipe Making Machinery

Foshan YXH Tube Mill & Mould Co.,Ltd offer different stainless steel tube mill pipe production line manufacturing machine, covering range from

4 mm to 426 mm

, and thickness is

0.2 mm to 8.0 mm

round pipe, square pipe, rectangular pipe, oval pipe and other irregular pipe as well.

Product Paramenters

|

Type

|

Pipe Diameter (mm)

|

Round pipe

Thickness (mm) |

Square Pipe

Thickness (mm) |

Capacity

(m/min) |

Weight

(T) |

Installation(L*W m)

|

Voltage

|

|

SZG40

|

8-31.8

|

0.2-2.0

|

0.3-1.5

|

1-20

|

5.5t

|

20*1.0m

|

220V/380V/415V/440V

|

|

ZG40

|

15.88-50.8

|

0.2-2.0

|

0.3-1.5

|

1-15

|

6t

|

21.5*1.1m

|

|

|

BBZG40

|

15.88-50.8

|

0.2-2.0

|

0.3-2.0

|

1-15

|

6.5t

|

21.5*1.1m

|

|

|

BZG40

|

12.7-63.5

|

0.3-2.0

|

0.3-2.0

|

1-10

|

6.5t

|

21.5*1.1m

|

|

|

ZG50

|

25.4-76.2

|

0.4-3.0

|

0.4-2.5

|

1-7

|

10t

|

24*1.2m

|

|

|

ZG60

|

38.1-114

|

0.5-3.0

|

0.5-3.0

|

1-5

|

12t

|

26*1.4m

|

|

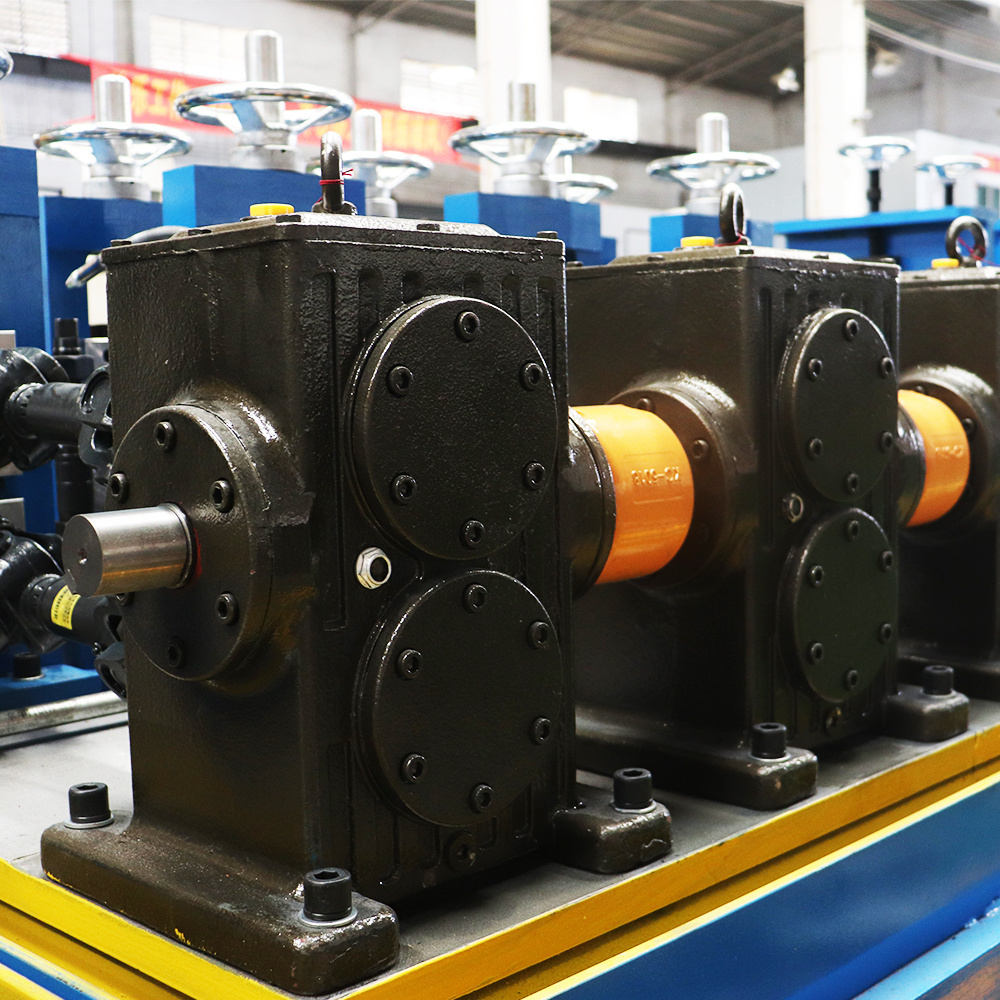

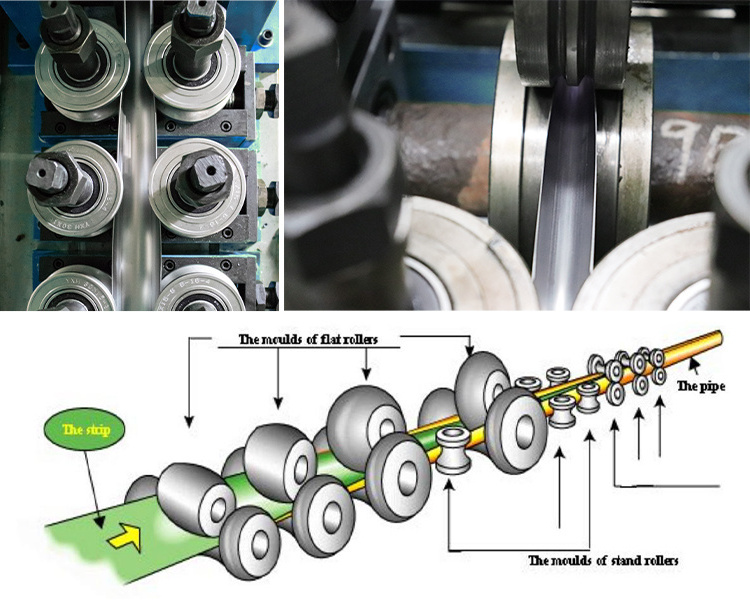

Machine parts

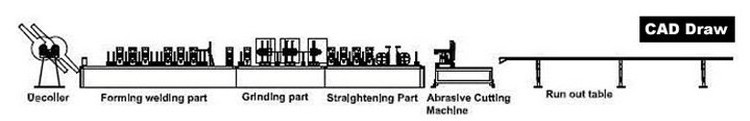

Uncoiler&Forming section

The steel coil is installed on the uncoiler, which content and transports the steel strip to the forming section, and the steel strip passing through the forming section is formed into a pipe.

Welding section

The formed pipe will have a gap, reach the welding section, and connect the weld through the welding gun. Become a sealed tube.

Grinding section

After welding, the weld will be slightly raised, after grinding section, the surplus part will be polished off. The tube will become smooth.

Sizing,Straightening&Cutting

The pipe is further fixed in the sizing,straightening section, passes through the turk head, and finally enters the cutting section to cut off the pipe.

Machine advantage

Industrial gearbox,double motor can provide much more stronger power to support the pipe manufacture,making the pipe manufacture faster and more precision.

More Advantage

Why Choose Us:

Our 4414 arrangement design can highly reduce scratches and also our moulds use the best materials to produce, and special mould install arrangement design.

Why Choose Us

Experience Export team:

Our foreign trade team has more than 10 years of export experience. Don't worry about any export clearance issues.

After Service--Provide service 24 hours*7 days per week

1.Test the tube mill machine before shipment

2.Provide technical guidance relate to use the tube making machine

3.Provide the spare parts at cost price after warranty period

4.Collect the feedback for tube mill machine working

5.Provide long-term technical assistance

6.Offer the professional engineer to help you improve the output ,reduce the waste and decrease the cost.

We use steel wire and wooden frame to fix the pipe making machine;

In addition, used shockproof film to protect the main motors.

We use the container to deliver goods to our customer. Generally speaking, we start at FOSHAN port, but we also can start at other port according to customer's need.

Hot Searches