The productsconfirms to ASTM D-4236,all of our products have passed RoHS, REACH, CPSIA, PAHS, EN71 ,UL.

- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

other

-

Place of Origin:

-

Guangdong, China

-

Main Raw Material:

-

Double Components Adhesives

-

Usage:

-

Flooring Paiting

-

Application Method:

-

Pouring after mixing

-

State:

-

Liquid State

-

Brand Name:

-

PONY RESIN

-

MOQ:

-

1 KG

-

Color:

-

Transparent

-

Advantage:

-

Durable and Scratch Resistant

-

Mix Ratio:

-

A:B=2:1/3:1

-

MSDS/SDS:

-

VOC Free

-

Private Labels:

-

OEM&ODM

-

Super Gloss:

-

UV Resistance,Scratches,Satin,heat resistance

-

100% Solid:

-

No odor

Quick Details

-

CAS No.:

-

61788-97-4

-

Other Names:

-

Epoxy Resin and Hardener

-

MF:

-

(C11H12O3)n

-

EINECS No.:

-

other

-

Place of Origin:

-

Guangdong, China

-

Main Raw Material:

-

Double Components Adhesives

-

Usage:

-

Flooring Paiting

-

Application Method:

-

Pouring after mixing

-

State:

-

Liquid State

-

Brand Name:

-

PONY RESIN

-

MOQ:

-

1 KG

-

Color:

-

Transparent

-

Advantage:

-

Durable and Scratch Resistant

-

Mix Ratio:

-

A:B=2:1/3:1

-

MSDS/SDS:

-

VOC Free

-

Private Labels:

-

OEM&ODM

-

Super Gloss:

-

UV Resistance,Scratches,Satin,heat resistance

-

100% Solid:

-

No odor

Products Description

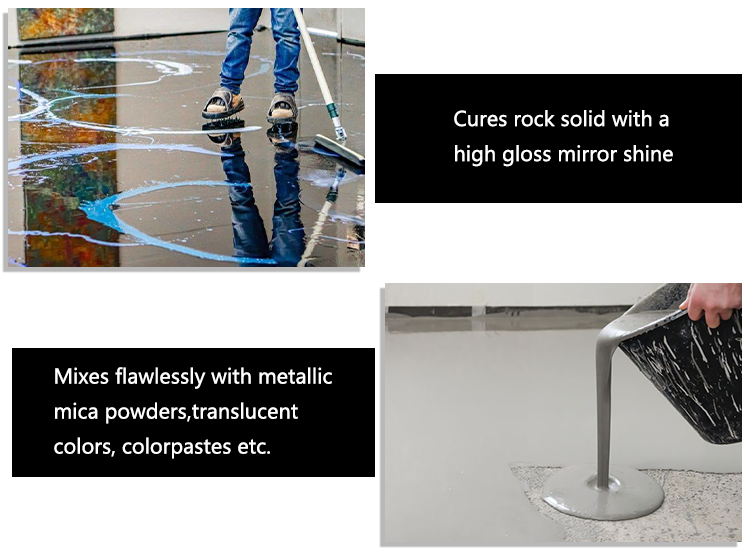

DIY Pearlescent Metallic Epoxy Floor Coating Self Leveling Flooring Kits

DongGuan Xiaoma Chemical is a professional glue and adhesive manufacturer in China .

DongGuan Xiaoma Chemical is a professional glue and adhesive manufacturer in China .

Focus on the research and development of high transparent crystal resin adhesive, producing for 20 years.

The main product is clear epoxy

casting resin, epoxy art resin, doming resin, epoxy paving resin and clear epoxy coating.

Designed for commercial, industrial, and residential concrete, cement, wood and tile Floor coating.

It is a 2 component 100% solids, zero VOC floor coating system that is used in a wide variety of applications:

* High build color coat for a host of decorative concrete systems;

* The high performance, self-leveling characteristics generate the premier balance of strength, flexibility, and chemical

resistance that is both user-friendly and extremely durable;

* Ideally suited for any commercial or residential setting: manufacturing facilities, warehouses, bars, clubs, retail stores,

automotive showrooms, residential interiors, garage floors, gyms, locker rooms, stadiums, or anywhere that an exceedingly

resilient floor is desired.

casting resin, epoxy art resin, doming resin, epoxy paving resin and clear epoxy coating.

Designed for commercial, industrial, and residential concrete, cement, wood and tile Floor coating.

It is a 2 component 100% solids, zero VOC floor coating system that is used in a wide variety of applications:

* High build color coat for a host of decorative concrete systems;

* The high performance, self-leveling characteristics generate the premier balance of strength, flexibility, and chemical

resistance that is both user-friendly and extremely durable;

* Ideally suited for any commercial or residential setting: manufacturing facilities, warehouses, bars, clubs, retail stores,

automotive showrooms, residential interiors, garage floors, gyms, locker rooms, stadiums, or anywhere that an exceedingly

resilient floor is desired.

Clear Epoxy Primer/Base Coat (A:B=2:1)

•

To penetrate deeper into the pores in order to achieve a better mechanical bond and produce a thinner epoxy film or tie coat that the much thicker base coat can chemically fuse with.

Clear Clear Epoxy Middle Coat (A:B=2:1)

• Mix with Metallic Color Pigments to have metallic effect epoxy floor coating and countertops coating.

• Mix with Metallic Color Pigments to have metallic effect epoxy floor coating and countertops coating.

High Gloss Epoxy Top Coat (A:B=2:1)

• Waterproof Barrier, Against Moisture, Impact Resistance, Scratch Resistance, Anti-slip and UV Stable.

• Waterproof Barrier, Against Moisture, Impact Resistance, Scratch Resistance, Anti-slip and UV Stable.

Feature

|

Part

|

A

|

B

|

||

|

Color

|

Transparent

|

Transparent

|

||

|

Specific gravity

|

1.15

|

0.96

|

||

|

Viscosity (25°C)

|

350-800CPS

|

150 -350CPS

|

||

|

Mixing ratio

|

A: B = 2:1/3:1

|

|

||

|

Hardening conditions 25 ℃

|

Light Foot traffic :24-48hours 72 hours for vehicular use and other heavy traffic.

|

|

||

|

Usable time

|

25°Cx40min (100g)

|

|

||

|

Usage

|

Primer

(optoinal) : 0.1kgs per square meters thickness 0.1mm

Middle

coating:thickness 1mm, require 1kgs per SQ.M .

Coloring

: 4-6% around (more or less will be as per color effect).

2 options of

top

:1) 0.3kgs epoxy per SQ.M; 2) 0.06kgs water based PU resin per SQ.M

|

|

||

|

Application

|

Garage floor coating ,Industry floor coating ,Residential Floor coating, Commercial floor coating and designer floors: showroom,shop,hotel ,ordesigner living space

|

|

||

|

Free Samples

|

Available 200 grams to test quality

|

|

||

|

Contact Us, We Will Provide You :

1. Good price with stable quality: WIN-WIN cooperation to support your business;

2. OEM with your target packing size and labeling your brands;

3.Fast delivery 3~5 days ,and logistic service support ;

|

|

|

||

|

Item

|

Package

|

Coverage Data

|

|

Epoxy Primer

|

5 kg/barrel, 15kgs kit

|

0.15 kg/ sqm @1mm

|

|

Epoxy Middle Coat

|

5 kg/barrel, 15kgs kit

|

0.75 kg/ sqm @2mm

|

|

Epoxy Top Coat

|

5 kg/barrel, 15kgs kit

|

0.15 kg/ sqm @1mm

|

|

Color Pigments

|

1kg/bag

|

0.015kg/sqm

|

Operation

Steps epoxy flooring :

Step 1.Materials and Tools preparation

Step 2: Preparing the Floor

1.

Mix the

epoxy primer

thoroughly and evenly;

2.

Fill and cracks, holes or gaps

in the floor to create a flat, smooth surface; For this step we used a small amount of the

epoxy primer

to mix with some Fumed Silica to create a epoxy filler, then left this to fully harden:

3.After cure ,

sand smooth

any rough or high spots and clean the floor thoroughly ,if find anywhere is not sealed well,can apply another thin layer of primer or clear middle coating resin.

Step 3: Weighing, Mixing and Pigmenting the Resin

1.

Single color or multiple colours

can be put to mix as per application area and projects design;

2.Lots of makers are using

metallic pigments to add effects like marbling

and we would always recommend thorough testing of a small panel to practise any effect you want to achieve before pouring the whole floor.

Step 4: Pouring & Curing the Resin

1.0ur epoxy coating resin has excellent self-levelling properties, so will only require light working to ensure that it has complete coverage and a consistent thickness - then the resin will do the rest of the work;

2.A small spreader will be used for pushing the resin around any obstructions like pipework or a pillar, but for the bulk of the spreading it's best to use a notched squeegee for speed and efficiency;

3.For big area,suggest 2 or more people to help mix ratio and pour;

4.0ur

epoxy floor resin

is

well self-degassing

so the bubbles will pop on their own,if floor is not presealed well,also may have few small area bubble,in this case just to overcome this we quickly passed over the surface with a propane torch to burst them.

Step 5: The Finished Floor and Application

1.Whole processing will require 2 days around, the resin will be touch dry after 24hours, but should leave it much longer time before bring any furniture or heavy appliances;

2.Single color or blended colour floor by combining solid color or metallic pigmemts to achieve a unique appearance.It will be also work by adding marbling or veins with metallic pigments or conntrasting colours, using the resin as a clear coat over a decorative floor like pennies, flakes,3D stickers ,vinyl records, crushed glass,mosaics and much more are all possibilities.

Product Show

Certifications

DIY Pearlescent Metallic Epoxy Floor Coating Self Leveling

Flooring KitsDesigned for commercial, industrial, and residential

concrete, cement, wood and tile Floor coating.

With our Epoxy Floor Coating System, you get a whole range of additional Advantages including:

• Industrial Strength Epoxy Waterproof Barrier, Against Moisture, Corrosion Inhibiting, Excellent Adhesion.

• Warm, comfortable feel underfoot.

• Non-slip finish. Abrasion resistant. Colour stability.

• Light and weather resistant. High UV stability under normal daylight conditions.

• Glossy, satin or mat surface. Reduced noise transfer providing quieter floors, reduces horizontal noise transmission.

• Seamless. Hygienic floor finish, low dust retention, easy to clean, resilient surface.

• Light reflecting aesthetic floor finish.

• Available in over 150 RAL colors

concrete, cement, wood and tile Floor coating.

With our Epoxy Floor Coating System, you get a whole range of additional Advantages including:

• Industrial Strength Epoxy Waterproof Barrier, Against Moisture, Corrosion Inhibiting, Excellent Adhesion.

• Warm, comfortable feel underfoot.

• Non-slip finish. Abrasion resistant. Colour stability.

• Light and weather resistant. High UV stability under normal daylight conditions.

• Glossy, satin or mat surface. Reduced noise transfer providing quieter floors, reduces horizontal noise transmission.

• Seamless. Hygienic floor finish, low dust retention, easy to clean, resilient surface.

• Light reflecting aesthetic floor finish.

• Available in over 150 RAL colors

Certificate complete, EU standard.

Hot Searches