- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SDCAD

-

Voltage:

-

Based on model

-

Dimension(L*W*H):

-

Based on model

-

Weight (KG):

-

600 kg

-

Application:

-

Conveying

-

After-sales Service:

-

Engineer Site Service + Online Support

-

Capacity:

-

10~160 T/h

-

Installation:

-

Engineer's Guide

-

Advantage:

-

20 Years Production Experiences

-

Feature:

-

Simple Operation

-

Function:

-

Conving Equipment

-

Control System:

-

Automatically Control

Quick Details

-

Power:

-

1.5 KW

-

Warranty:

-

2 years

-

Width or Diameter:

-

Other

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SDCAD

-

Voltage:

-

Based on model

-

Dimension(L*W*H):

-

Based on model

-

Weight (KG):

-

600 kg

-

Application:

-

Conveying

-

After-sales Service:

-

Engineer Site Service + Online Support

-

Capacity:

-

10~160 T/h

-

Installation:

-

Engineer's Guide

-

Advantage:

-

20 Years Production Experiences

-

Feature:

-

Simple Operation

-

Function:

-

Conving Equipment

-

Control System:

-

Automatically Control

Product Overview

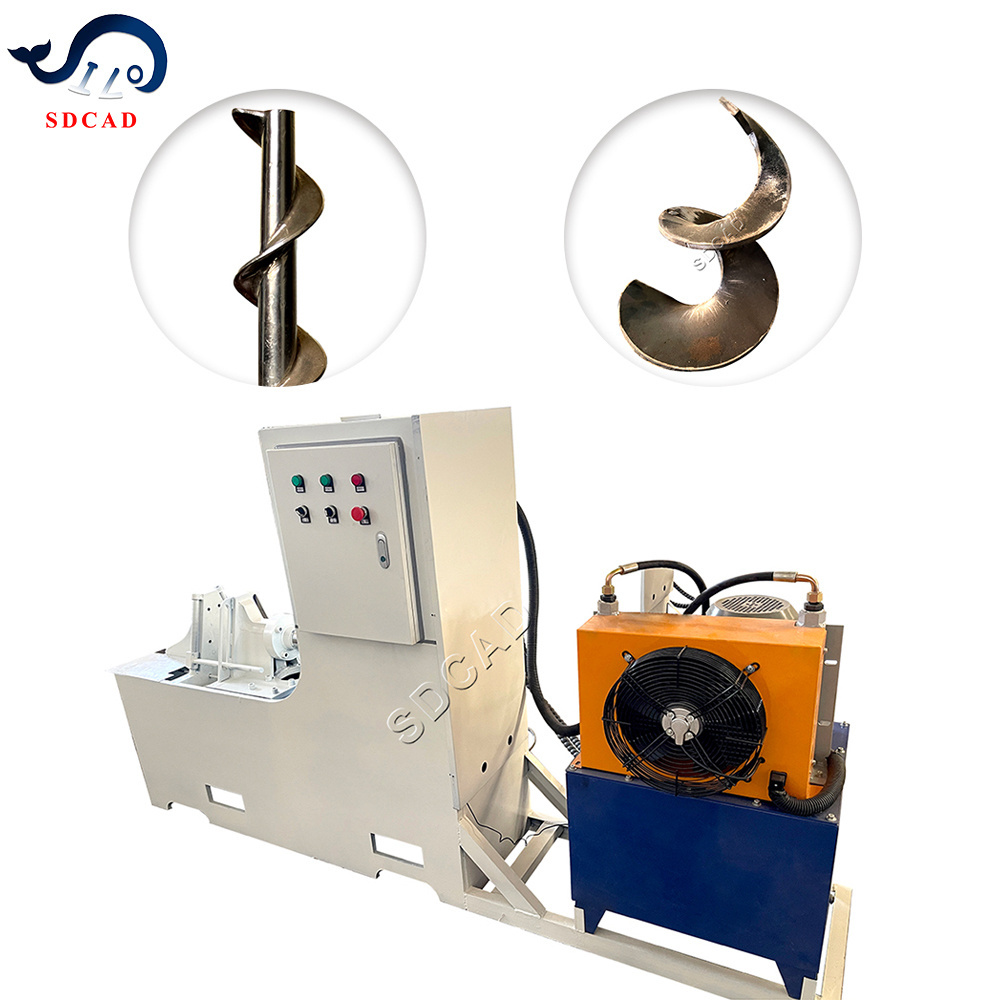

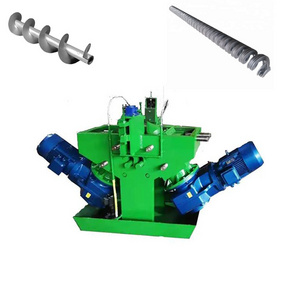

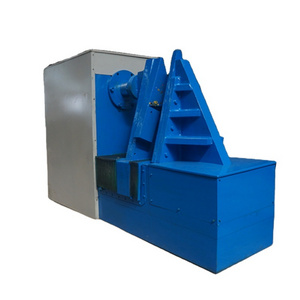

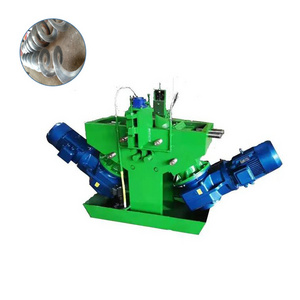

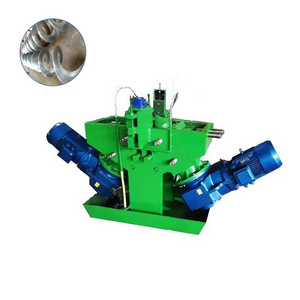

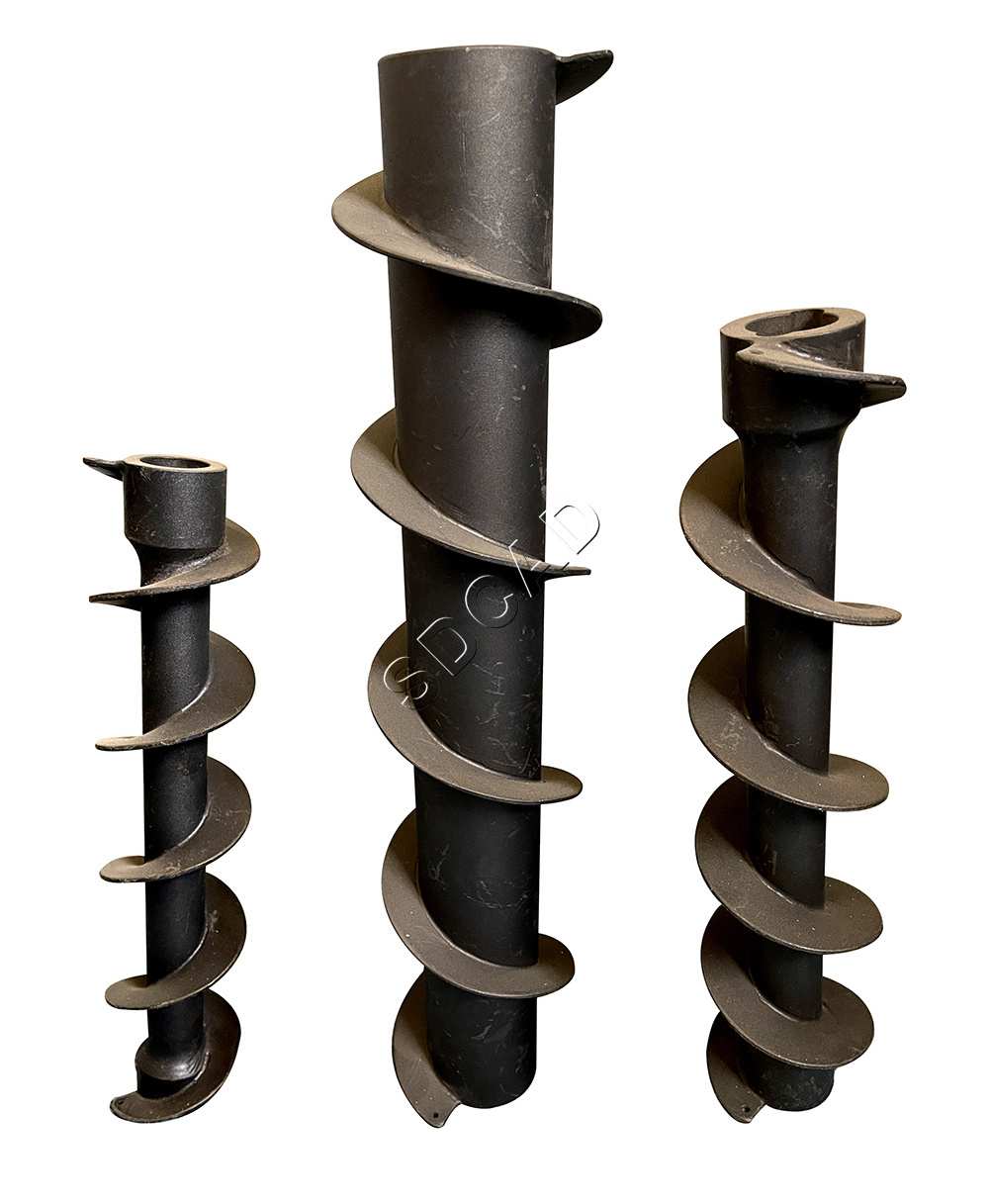

Spiral blade forming machine

1. It has high production efficiency and saves raw materials. Continuous cold-rolled spiral blades have the advantages of smooth surface, high hardness, wear resistance, one-time forming, and continuous no welds.

2. The conveyor machine uses rotating continuous spiral blades to push materials. The continuous spiral blades are made of high-quality imported high-strength wear-resistant steel. After forming, the pitch error is less than 5mm and the blade surface is smooth, ensuring uniform and stable material transportation. During production It adopts cold work hardening surface cold rolling treatment, and its hardness and wear resistance are about twice that of ordinary blades. The high-precision manufacturing of the blades ensures that the pipe body is filled when the material is transported.

|

Model

|

YJ3-80

|

YJ3-100

|

|

voltage

|

380V 50Hz

|

380V 50Hz

|

|

weight

|

Approximately 0.6T

|

Approximately 1T

|

|

size

|

1500 * 400 * 600mm

|

2000 * 550 * 1400mm

|

|

Processing thickness

|

2-8mm

|

2-12mm

|

|

Inner diameter range

|

>12mm

|

>20mm

|

|

Outer diameter range

|

<300mm

|

<400mm

|

|

Single side width of the mold

|

180mm

|

230mm

|

|

pitch

|

80-200mm

|

100-400mm

|

|

Motor power

|

3kw

|

3kw

|

|

Fuel tank capacity

|

30L

|

60L

|

|

Fuel tank size

|

300 * 200 * 500mm

|

500 * 300 * 400mm

|

|

pressure

|

15T 10Mpa

|

25T 20Mpa

|

|

control

|

Foot switch - dual signal

|

Foot switch - dual signal

|

PRODUCT SPECIFICATIONS

|

Model

|

Unilateral width

|

pitch

|

|

#100

|

70mm

|

75-160mm

|

|

#120

|

80mm

|

100-200mm

|

|

#180

|

140mm

|

80-200mm

|

|

#245

|

180mm

|

90-400mm

|

|

#260

|

210mm

|

180-400mm, max 450mm

|

|

#360

|

285mm

|

180-600mm

|

|

#500

|

400mm

|

180-900mm, max 1000mm

|

Model

▷ Description

The cold-rolled spiral blade machine has changed the traditional method of making spiral blades in the past. The spiral blade forming machine has promoted the development of industrialization. The spiral blade is mainly used in conveying machinery, stirring machinery, and pile drilling machinery, pharmaceutical machinery, environmental protection machinery industry. According to the characteristics of different conveying materials, screw conveyors can be divided into shaftless screw conveying and shafted screw conveying. The cold-rolled spiral blade machine produced by our company can process various specifications of carbon steel spiral blades and stainless steel spiral blades through the conical roller extrusion method. precise.

▷ Features

1. It is welded by high-quality thickened steel plate, which is durable and long-lasting, with high dimensional accuracy and surface hardness. 2. The finished product has a high reasonable rate, a rounded arc, and easy welding. 3. The operation is simple, the structure is reasonable, the machining accuracy is high, and various specifications can be processed. 4. The spiral blade has the advantages of smooth surface, no welding seam, high hardness, good wear resistance, smooth conveying and reducing material damage rate.

SALES AND SERVICE NETWORK

Bolted silo

Big silo project

Frame Bolted Silo

Mobile Silo with Load Cell

Horizontal Container Silo

Mobile Horizontal Silo

Small Bag Hopper

Mobile Telescopic Loading Spout with Bag Hopper

Bitumen Heating Tank

800-500000 Ton Cement Storage Steel Silo

10000 Ton Cement Storage Steel Silo

FAQ

Are you a manufacturer or Trader?

We are a professional manufacture , we have our own R&D team and sales team, we provide one-stop service.

What is your payment term?

We accept T/T, L/C at sight, Western Union, Paypal etc.

How long is the validity of quotation?

Generally, our price is valid within one month from the date of quotation . The price will be adjusted appropriately according to the price fluctuation of raw materials and changes in market .

What is your delivery time?

Usually, we make merchandise inventory, if we have the products in stock, the delivery time is 5-10 days after receiving the

deposit. If we don't have the products in stock, we will arrange the production right now, the delivery time will be 10-30 days,It depend on the order quantity.

Do you provide OEM/ODM Service?

Yes, offer me necessary information, we provide custom-make service to meet different needs of global clients with different

budgets. How can we ensure quality?

We are a professional manufacture , we have our own R&D team and sales team, we provide one-stop service.

What is your payment term?

We accept T/T, L/C at sight, Western Union, Paypal etc.

How long is the validity of quotation?

Generally, our price is valid within one month from the date of quotation . The price will be adjusted appropriately according to the price fluctuation of raw materials and changes in market .

What is your delivery time?

Usually, we make merchandise inventory, if we have the products in stock, the delivery time is 5-10 days after receiving the

deposit. If we don't have the products in stock, we will arrange the production right now, the delivery time will be 10-30 days,It depend on the order quantity.

Do you provide OEM/ODM Service?

Yes, offer me necessary information, we provide custom-make service to meet different needs of global clients with different

budgets. How can we ensure quality?

The final inspection is always carried out before shipment.

How to install the equipment after purchasing?

We will provide a professional installation video to illustrate.Also provide a manual.

How to install the equipment after purchasing?

We will provide a professional installation video to illustrate.Also provide a manual.

Do you offer a guarantee?

Yes, we guarantee our product for one year. Provide after-sales service support with and agricultural technical support.

What is your MOQ?

1Sets

Yes, we guarantee our product for one year. Provide after-sales service support with and agricultural technical support.

What is your MOQ?

1Sets

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Hot Searches