- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

UNIQUE

-

Motor Power:

-

20.7kw

-

Charging Capacity:

-

750L

-

Reclaiming capacity:

-

500L

-

Speed of Mixing Drum:

-

35r/min

-

Water Supply Mode:

-

Water Pump Motor

-

Working Cycle Period:

-

60s

-

Discharge Way:

-

Pneumatic or Hydraulic

-

Outline Dimension:

-

2220x2071x1880mm

-

Weight (KG):

-

3500 kg

-

Product name:

-

Cocnrete Mixer

-

Mixing blades:

-

High manganese steel alloy and chromium alloy

-

Scaleboard:

-

High manganese steel alloy and chromium alloy

-

Lubricating pump:

-

Electric or Manual

-

PLC:

-

Siemens

-

Mixing star*Mixing blade:

-

1*2

-

Weight:

-

2500kg

-

Discharge height:

-

3.8M or customized height

-

Theoretical productivity:

-

≥25 m3/h

-

Color:

-

Can be customized

Quick Details

-

Mixing Power:

-

18.5kw

-

Productivity:

-

22M³/H

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

UNIQUE

-

Motor Power:

-

20.7kw

-

Charging Capacity:

-

750L

-

Reclaiming capacity:

-

500L

-

Speed of Mixing Drum:

-

35r/min

-

Water Supply Mode:

-

Water Pump Motor

-

Working Cycle Period:

-

60s

-

Discharge Way:

-

Pneumatic or Hydraulic

-

Outline Dimension:

-

2220x2071x1880mm

-

Weight (KG):

-

3500 kg

-

Product name:

-

Cocnrete Mixer

-

Mixing blades:

-

High manganese steel alloy and chromium alloy

-

Scaleboard:

-

High manganese steel alloy and chromium alloy

-

Lubricating pump:

-

Electric or Manual

-

PLC:

-

Siemens

-

Mixing star*Mixing blade:

-

1*2

-

Weight:

-

2500kg

-

Discharge height:

-

3.8M or customized height

-

Theoretical productivity:

-

≥25 m3/h

-

Color:

-

Can be customized

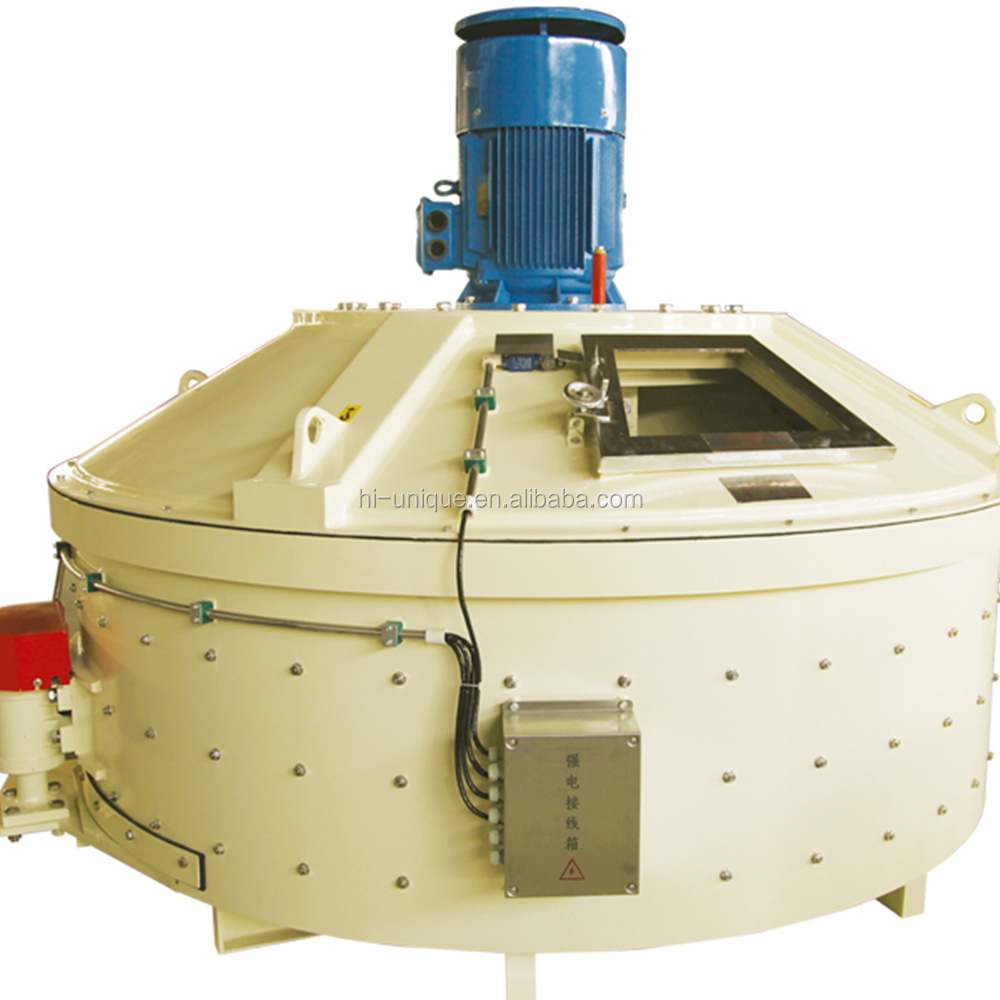

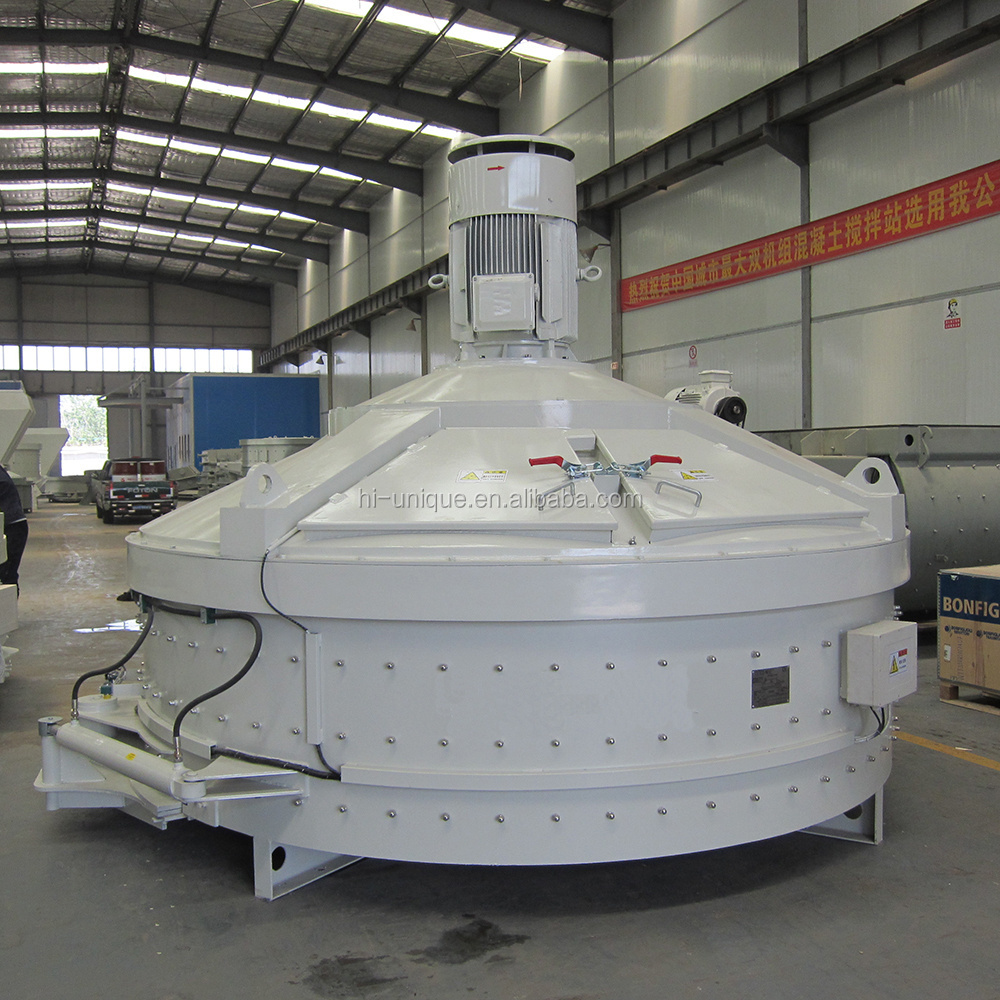

JN500 Planetary Concrete Mixers widely apply to produce precast concrete, common commercial concrete and high performance concrete. It is suitable for mixing dry hard concrete (roller compacted concrete). It is widely used in the production of building blocks and prefabricated parts, and also can be used to produce of steel fiber reinforced concrete, color concrete and dry mortar, erc.

The mixing blade and scaleboard

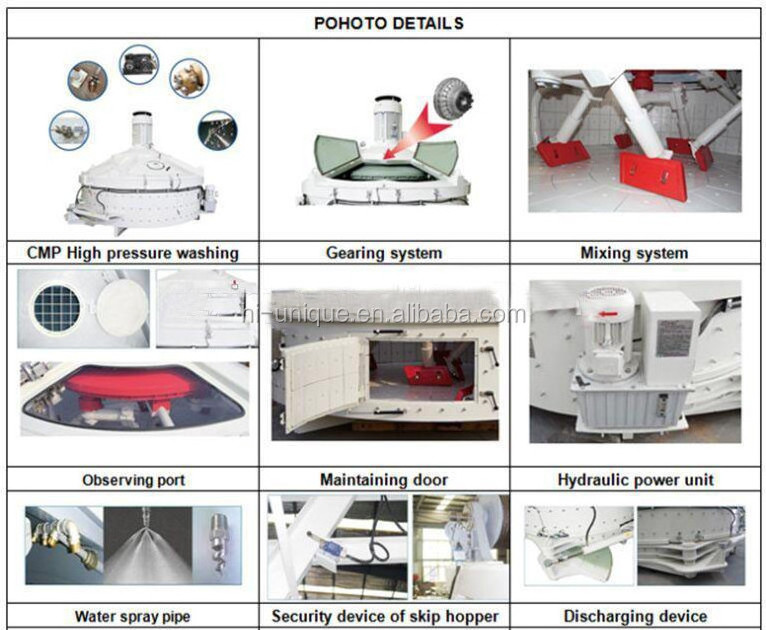

1. Steady Driving.

The power transmission is realized by a hard surface gearbox

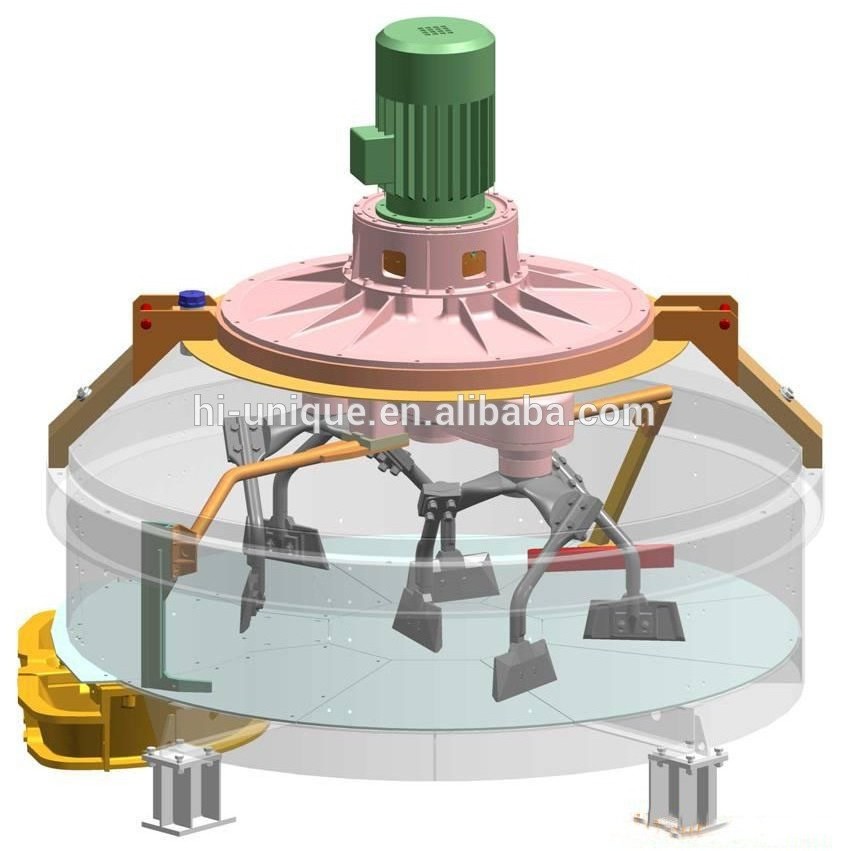

2. High Mixing Efficiency.

The gear box drives the mixing arms to move with complex track, and the mixing is turbulent, then the mixer works more effectively.

3. Homogeneous Mixing.

Mixing blades are composed of several groups of mixing arms, which covers the entire mixing region. Both revolution and rotation of mixing blades ensure the homogeneity of the material. As the picture shows, mixing blades’ motion track covers the whole drum after a cycle.

4. Multiple Discharging Method.

According to various demands of customers, the discharging door can be operated hydraulically, pneumatically or manually.

5. Special Designed Water Sprayer

Special designed sprayer makes the water cloud cover more area and ensure the even distribution of the materials.

6. Easy to maintain and no leakage problem. Transmission system (including motor) is located at the top of mixing drum, completely separated from the concrete. It’s convenient for maintenance and there is no leakage problem at the shaft end.