- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

2000 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380v/50hz

-

Power:

-

2.2-75kw

-

Key Machines:

-

cassava chipping machine, cassava drying machine

-

Product Type:

-

dry cassava chips

-

Product name:

-

Dried Cassava Chips Production Cassava Chipping And Drying Machine

-

Supplier:

-

factory,manufacturer

-

Function:

-

High Temperature High Pressure Sterilizing

-

Service life:

-

20years

-

Certification:

-

CE & ISO9001 2015

-

Advantage:

-

Easy Operation High Efficiency

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Warranty:

-

2 Year

-

After Warranty Service:

-

Online support

-

Package:

-

Standard Package

Quick Details

-

Machinery Capacity:

-

300-500kg/h

-

Brand Name:

-

GOODWAY

-

Dimension(L*W*H):

-

processing line

-

Weight:

-

2000 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380v/50hz

-

Power:

-

2.2-75kw

-

Key Machines:

-

cassava chipping machine, cassava drying machine

-

Product Type:

-

dry cassava chips

-

Product name:

-

Dried Cassava Chips Production Cassava Chipping And Drying Machine

-

Supplier:

-

factory,manufacturer

-

Function:

-

High Temperature High Pressure Sterilizing

-

Service life:

-

20years

-

Certification:

-

CE & ISO9001 2015

-

Advantage:

-

Easy Operation High Efficiency

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Warranty:

-

2 Year

-

After Warranty Service:

-

Online support

-

Package:

-

Standard Package

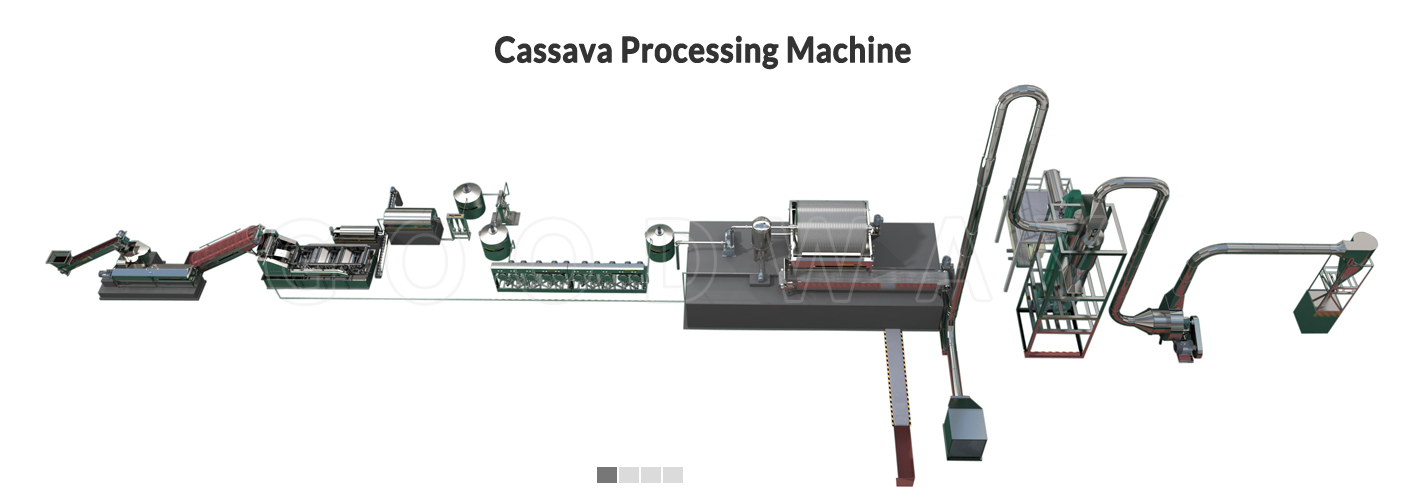

500 Kg/Hour Dried Cassava Chips Production Cassava Chipping And Drying Machine

Goodway Tuberous Materials Processing Machine Solutions:

* Cassava Starch Processing Machine(Tapioca Starch Processing Machine);

* Potato Starch Making Machine;

* Sweet Potato Starch Making Machine;

* Canna Edulis Ker Starch Processing Machine;

* Cassava Flour(HQCF) Machine(High Quality Cassava Flour Processing Machine);

* Cassava Garri Processing Machinery(Gari Processing Machine);

* Cassava Fufu Processing Machine(Fufu Machine);

* Cassava Chips Making Machine(Cassava Cutting Production Line);

* Yam Flour Processing Machine(Amala Yam Flour Making Machine).

* Potato Starch Making Machine;

* Sweet Potato Starch Making Machine;

* Canna Edulis Ker Starch Processing Machine;

* Cassava Flour(HQCF) Machine(High Quality Cassava Flour Processing Machine);

* Cassava Garri Processing Machinery(Gari Processing Machine);

* Cassava Fufu Processing Machine(Fufu Machine);

* Cassava Chips Making Machine(Cassava Cutting Production Line);

* Yam Flour Processing Machine(Amala Yam Flour Making Machine).

Products Description

|

CASSAVA CHIPS PROCESSING LINE PRODUCTION SCALE:

|

|

|

|

|||

|

Dry chips per day

|

|

Dry chips per day

|

|

|||

|

6 TONS

|

|

12 TONS

|

|

|||

|

the above data is calculated based on 24 hours of processing per day

|

|

|

|

|||

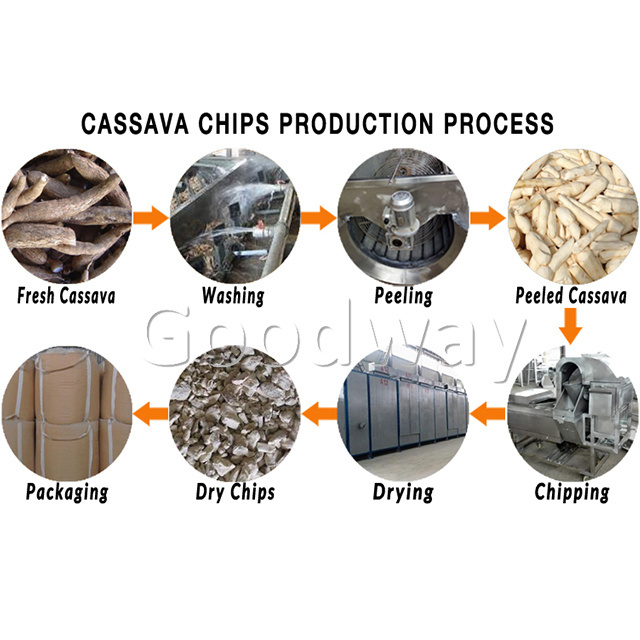

The production of cassava chips comprises the machines such as cassava washing machine, peeling machine, chipping machine, cassava chips drying machine - belt type dryer and packaging machine. We have provided below a brief description on the main steps of the cassava chips production process.

Details Images

Cassava washing machine

wash the fresh cassava roots in clean water to remove mud, sand and other impurities.

Cassava peeling machine

peel the cassava roots to remove the outer brown skin and partial inner thick cream layer, also avoid over damaging of raw materials.

Cassava chipping machine(cassava chipper)

cut the peeled cassava roots to produce thinner and more uniform slices than chipping by hand.

Cassava chips drying machine(belt type dryer)

effectively dry the cassava chips or slices to low moisture content by principle of heat transfer exchange.

Installation Instructions

Installation invoice

A: one guy 100USD one day for installation guide

B: we offer custom design of machine connection and factory layout design for our customer's project.

C: we will offer pipes and small tools during installation.

Hot Searches