- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HKY

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

4.5M*1.0M*1.4M

-

Weight:

-

3.8 kg

-

certification:

-

CEBV

-

control system:

-

PLC

-

screen:

-

color touch screen

-

motor brand:

-

famous in China

-

guarantee:

-

2year

-

After Warranty Service:

-

Video technical support

-

Certification:

-

BV

Quick Details

-

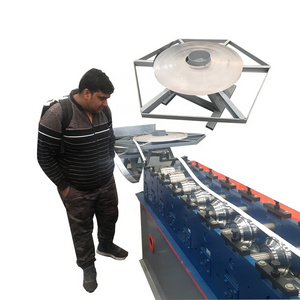

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

0-60m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HKY

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

4.5M*1.0M*1.4M

-

Weight:

-

3.8 kg

-

certification:

-

CEBV

-

control system:

-

PLC

-

screen:

-

color touch screen

-

motor brand:

-

famous in China

-

guarantee:

-

2year

-

After Warranty Service:

-

Video technical support

-

Certification:

-

BV

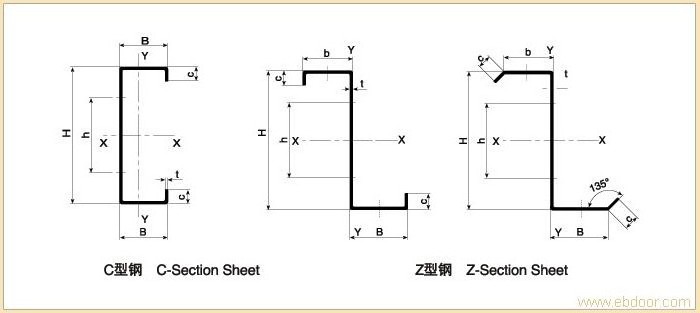

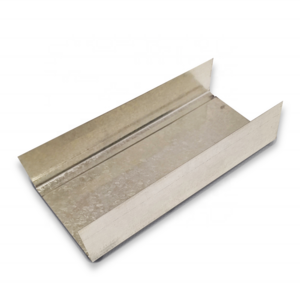

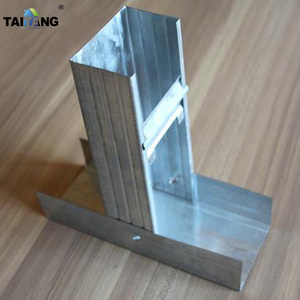

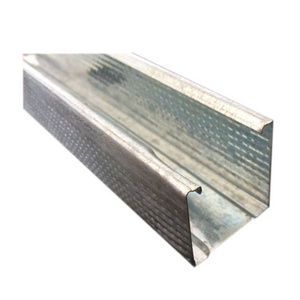

Steel forming machine is to produce light steel main equipment, the use of steel or steel cold-formed after forming, rolling production models of a variety of specifications purlins finished.

The wall thickness of the product out of the apparatus can be made very thin, but also greatly simplifies the production process, improve production efficiency. Wall thickness can be produced hot-rolled with the general method but difficult to produce a uniform cross-sectional shape of the complex variety of profiles and cold-formed steel of different materials.

economical and reasonable, saving materials

The section is economical and reasonable, saving materials. In the same weight and cross section area, cross section coefficient of cold-formed profiles is higher than that of hot-rolled profile. Under the same load, can reduce the structural weight, saving materials.The production can be matched with punching, embossing, sculpture and other processes, can meet different needs, forming speed of up to 250m per minute.

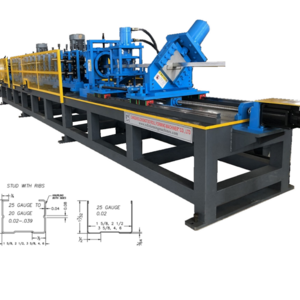

Rollers

High quality rollers will help to produce the beautiful and high quality profile. That will satisfy your customers.

Using high quality 95mm thick shaft, the strength is more durable.

Machine body

The main body of the body without welding, all the use of cast steel, the whole machine will not produce stress and lead to the host body deformation.

PLC Control System

Usually we prodvide the Delta PLC control system, but we can make that according to your need. You need which brand, then we send to you which brand.But the long life of that will bring you great benefit .

Our Factory

Our Exhibition Hall

Our Reception

Our Workshop

Botou Huikeyuan Engineering Control Co.,Ltd was founded in 1989 and has become a recognized leader in the manufacture of Cold Roll forming machines and equipments

Our excellent reputation for sound and innovative engineering and 20 years of experience have brought us recognition for offering our customers the ultimate in efficiency for roll forming equipments and toolings

Why choose us?

1.We can make and design all kinds of roll forming machine according to customer's requests.

2.This is a very perfect and durable equipment. We have more than 13 years experiences.

3.This kind of machine has the best quality and the best price. It has accurate measurement and easy operating.

4.We can design and manufacture the special type machine according to the customers' requirement and we could provide technical guiding, production, installation, debugging and maintenance service to all customers.

5. Our product has been exported to many regions and won high reputation because of the high quality and reasonable price.

HKY, as a well known brand name of a roll forming equipments manufacturer in China, has exported its equipments and machines to more than 60 countries and areas over the world, such as Russia, India, UK, Australia, USA, KZ, TJK, Malaysia, Nigeria, Romania, Albania and it has received excellent reputation. In the future, we are committed to better equipments and sales service and meeting customers' requirements when and where they need.

1. Shock bubble film

2. Suitable carton size

3. Shock bubble film

> Plastic Packing / Common Packing. Water-proof, Rust Prevention and Dust Prevention.

>By sea or other ways. In general, by sea, the port of loading is XINGANG PORT. It is only need 2 hours from our Company and Factory to Xingang Port, Tianjin City.

Q: How can I contact you?

A: Please look at my contact card. You can talk to me anytime. Or send me enquiry email, I will reply you in 24 hours and offer the optimum solution to you

Q: What is the status of After-sale Services for customers and machineries?

A: Engineers available to service machinery overseas. But the customers/buyer should pay for installation and commissioning fee 100$/day to our point account. We will provide the technical support for the whole life of the equipment and free training.

Q: How to visit our company?

A: 1.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour),then we can pick up you.

2.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours),then we can pick up you.3.Fly to Guangzhou aiport: By air From Guangzhou to Beijing airtpot; By high speed train From Beijing Nan to Cangzhou Xi (1 hour),then we can pick up you.

Q: How many years since you have been in this field?

A: Our company has been producing roll forming machines for almost 20years.We have rich experience for manufacturing and designing the machine.

> Warranty: 2 Years.

During the warranty period, it covers all spare parts of machines, if you find some spare parts were damaged,

those new spare parts will be supplied free by us, but normal wear and tear excepted. And the freight should be bore equally by both parties.

> We could provide technical guiding, production, installation, debugging and maintenance service to all customers. After the end of the warranty period, it's not free.

> We will provide the technical support for the whole life of the equipment.

>TERMS:

1. Delivery: in stock

2. Package: Export Standard package for container

3. Payment: TT(30% by TT in advance, 70% by TT after you inspect the machine )

4. Validity: good for 30days

Contact me

Michael Shen (Sales )

BOTOU HUIKEYUAN ENGINEERING CONTROL CO.,LTD

Add: Fuzhuang Development Zone Botou City, Hebei, China

Cel: +86 15533709565

Whatsapp/Wechat: +86 15533709565

Web : www.hkyrollformingmachine.com

we warmly weclome you to visit our facory!