- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Processing:

-

AAC Block Production Line

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

Hongfa

-

Voltage:

-

100kw more

-

Dimension(L*W*H):

-

128000*30000*8000mm

-

Weight (KG):

-

980000 kg

-

Land:

-

Depends on capacity

-

Installation:

-

Engineer Guidance

-

Raw material:

-

concrete / flyash / sand / lime /cement / gypsum

-

Product Name:

-

AAC Block Production Line

-

Keywords:

-

AAC Block Production Line

-

Advantage:

-

lightweight, Cost saving

-

Capacity:

-

50000cbm-300,000cbm

-

Products:

-

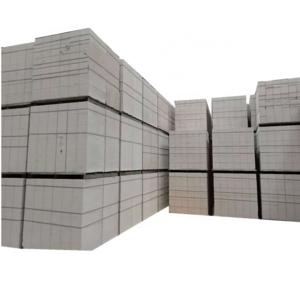

AAC blocks, ALC Panels

-

After-sales Service Provided:

-

Field installation, commissioning and training

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, AAC block production line

-

Brick Raw Material:

-

Sand or fly ash, gypsum, aluminium powder, etc

-

Production Capacity (Pieces/8 hours):

-

50,000cbm-300,000cbm per year

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Processing:

-

AAC Block Production Line

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

Hongfa

-

Voltage:

-

100kw more

-

Dimension(L*W*H):

-

128000*30000*8000mm

-

Weight (KG):

-

980000 kg

-

Land:

-

Depends on capacity

-

Installation:

-

Engineer Guidance

-

Raw material:

-

concrete / flyash / sand / lime /cement / gypsum

-

Product Name:

-

AAC Block Production Line

-

Keywords:

-

AAC Block Production Line

-

Advantage:

-

lightweight, Cost saving

-

Capacity:

-

50000cbm-300,000cbm

-

Products:

-

AAC blocks, ALC Panels

-

After-sales Service Provided:

-

Field installation, commissioning and training

Hongfa Ytong AAC Block Machine and Price AAC Block Plant Manufacturers Plant Cost AAC Block Production Line in India Iraq

Hongfa Ytong AAC Block Machine and Price AAC Block Plant Manufacturers Plant Cost AAC Block Production Line

• Hongfa AAC production line has a smooth process. The molds, side plates, and steam-curing cars each have independent circulation routes. All equipment does not cross operations, which greatly improves equipment operation efficiency and work safety.

• The control system adopts the internationally advanced centralized and segmented control method and adopts PLC control system. All processes are completed in the central control room and the ground division operation platform. The work realizes mechanized and automated production, with less labor and high production efficiency. Human errors cause little loss and the product qualification rate is high.

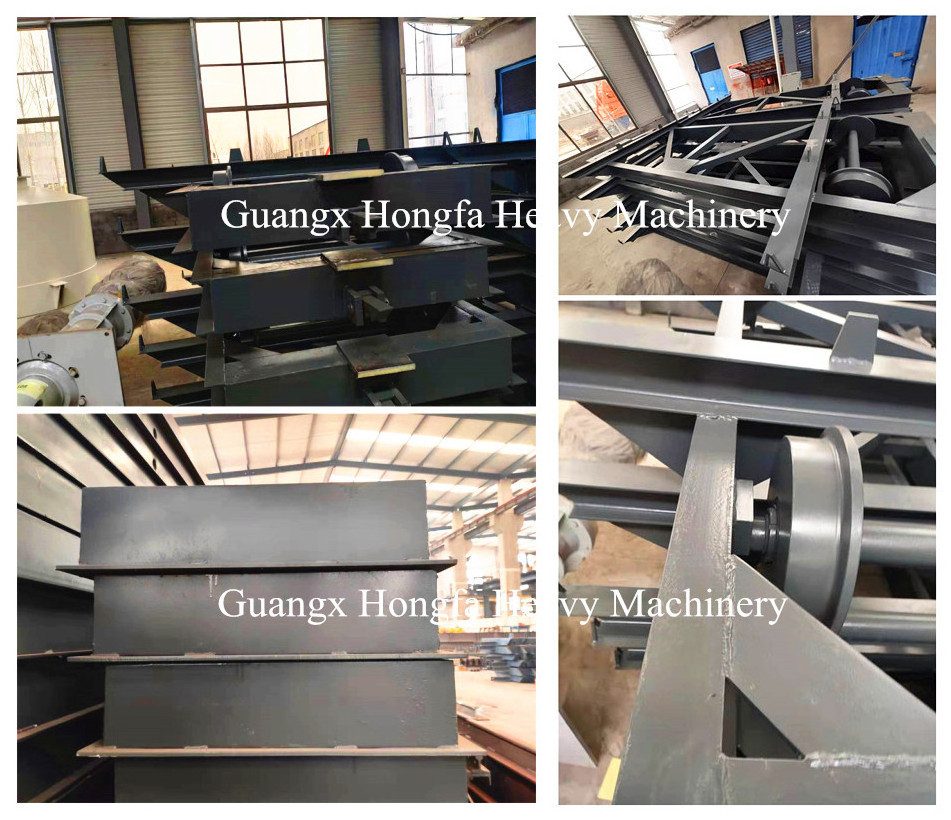

Raw material of machine

To make our AAC block production line reliable and durable, HONGFA FACTORY purchases

steel from famous steel manufacturers in China. We only use steel plates that have not been

rolled. A few underwater plasma cutting machines were purchased to guarantee

the high precision of our autoclaved aerated concrete production machines.

Welding workshop of autoclaved concrete blocks machine / gas block production line/AAC ALC panel prodution plant/Fly ash sand AAC block equipment

Welding robots were used to improve the productivity and welding performance.

Thus we can get consistent AAC machine equipment.

High technology for AAC bock plant machiney:

Testing Hongfa Hongfa Ytong AAC Block Machine and Price AAC Block Plant Manufacturers Plant Cost AAC Block Production Line /AAC line /Gas block production line before shipment

Hongfa Ytong AAC Block Machine and Price AAC Block Plant Manufacturers Plant Cost AAC Block Production Line in India Iraq

HHongfa Ytong AAC Block Machine and Price AAC Block Plant Manufacturers Plant Cost AAC Block Production Line running in our south of factory , welcome to visit us!

Main process flow of

Hongfa Ytong AAC Block Machine and Price AAC Block Plant Manufacturers Plant Cost AAC Block Production Line in India Iraq

|

1.Raw materils preperation for AAC plant: A, Milling sand ( fly ash no need mill) and to make slurry B, Lime: crushing - milling ( or to buy lime lowder directly) C, Gypsum:to mill with sand or lime or input with flyash then to make slurry directly.

|

|

2.Slurry batching: The prepared and stored raw materials to be used are metered, adjusted for temperature and concentration, and a small amount of dosing materials are metered on-site, and then fed to the stirring equipment in turn according to the process requirements.

|

| 3. Pouring: In this process, the materials that are put into the mixer after the previous batching process are measured and adjusted if necessary, and the materials that meet the time, temperature, and consistency requirements of the process are made, then pouring into the mold. The pouring process is an important process that can form a good pore structure, and it constitutes the core link of aerated production as the batching process. |

|

6.Cutting: The cutting process is to divide and shape the aerated concrete body to meet the appearance size requirements.

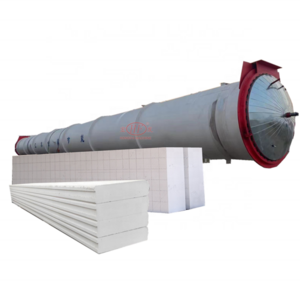

7.Autoclave curing: High-pressure steam curing of aerated concrete aac body. (Usually above 174.5 ℃) |

|

8. Out off Autoclave: Including finished aac products out of the autoclave, lifting, separation, inspection, packaging and cleaning and oiling of trolleys and bottom plates.

9.Waster recycle: waste cncrete cut away from green body and waste water from steam of autoclave. |

Hongfa Ytong AAC Block Machine and Price AAC Block Plant Manufacturers Plant Cost AAC Block Production Line in India Iraq

Advantages of the AAC block application

Application of AAC BLOCKS

Autoclaved Aerated Concrete Block are widely used as external wall panel (exterior wall panel), internal wall panel (interior wall panel), partition wall panel, flooring, roofing, fence, cladding, curtain wall and facade etc.

Autoclaved Aerated Concrete Block are widely used in different kinds of buildings, such as public facilities, industrial constructions, steel structure building, warehouse, workshop, stores, hospitals, hotels, apartments, villas, schools,

supermarkets etc.

Shipping Hongfa Ytong AAC Block Machine and Price AAC Block Plant Manufacturers Plant Cost AAC Block Production Line