- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Jedha

-

Model Number:

-

PU 17

-

Length:

-

Customized, <11.8m

-

Thickness:

-

50/75/100/120/150/200mm

-

Width:

-

950/1000/1150mm

-

Density:

-

40 Kg/M3

-

Paint:

-

PE/PVDF/SMP/HDP

-

Color:

-

Customized

-

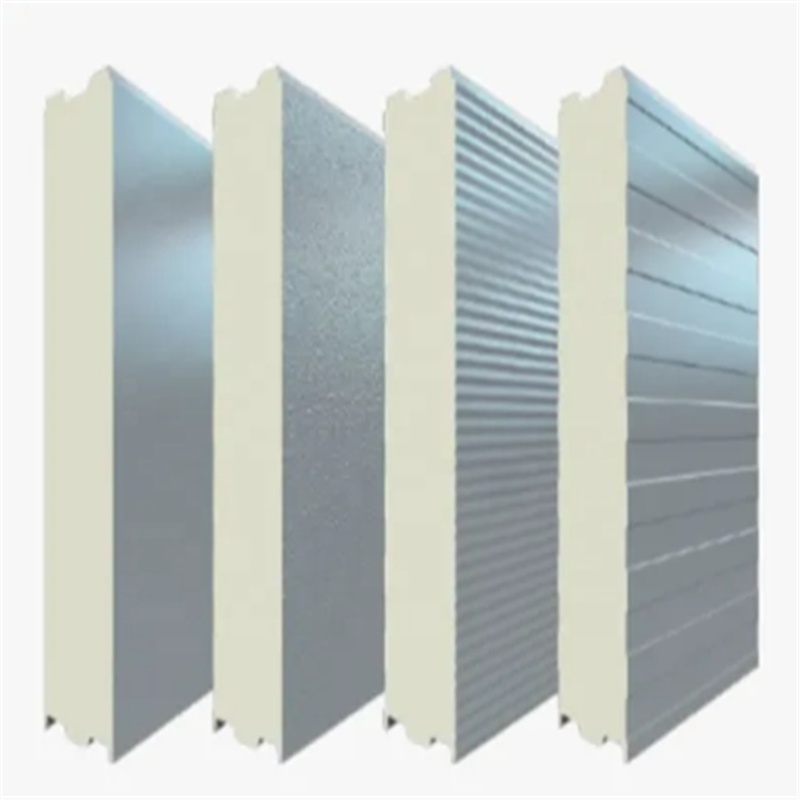

Core material:

-

EPS/PU/PIR/PUF/PUR/Rockwool/Glasswool

-

Interior Steel Thickness:

-

0.4mm-0.6mm

-

Exterior Steel Thickness:

-

0.4mm-0.8mm

-

Lead time:

-

15 Days after receiving your deposit

Quick Details

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

-

Application:

-

Leisure Facilities

-

Design Style:

-

Asian

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Jedha

-

Model Number:

-

PU 17

-

Length:

-

Customized, <11.8m

-

Thickness:

-

50/75/100/120/150/200mm

-

Width:

-

950/1000/1150mm

-

Density:

-

40 Kg/M3

-

Paint:

-

PE/PVDF/SMP/HDP

-

Color:

-

Customized

-

Core material:

-

EPS/PU/PIR/PUF/PUR/Rockwool/Glasswool

-

Interior Steel Thickness:

-

0.4mm-0.6mm

-

Exterior Steel Thickness:

-

0.4mm-0.8mm

-

Lead time:

-

15 Days after receiving your deposit

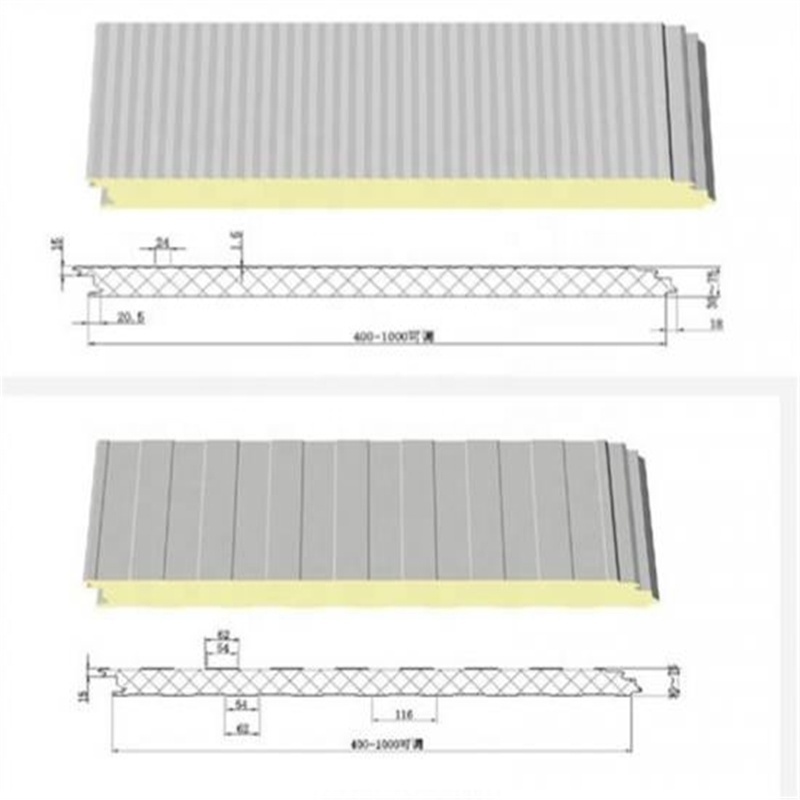

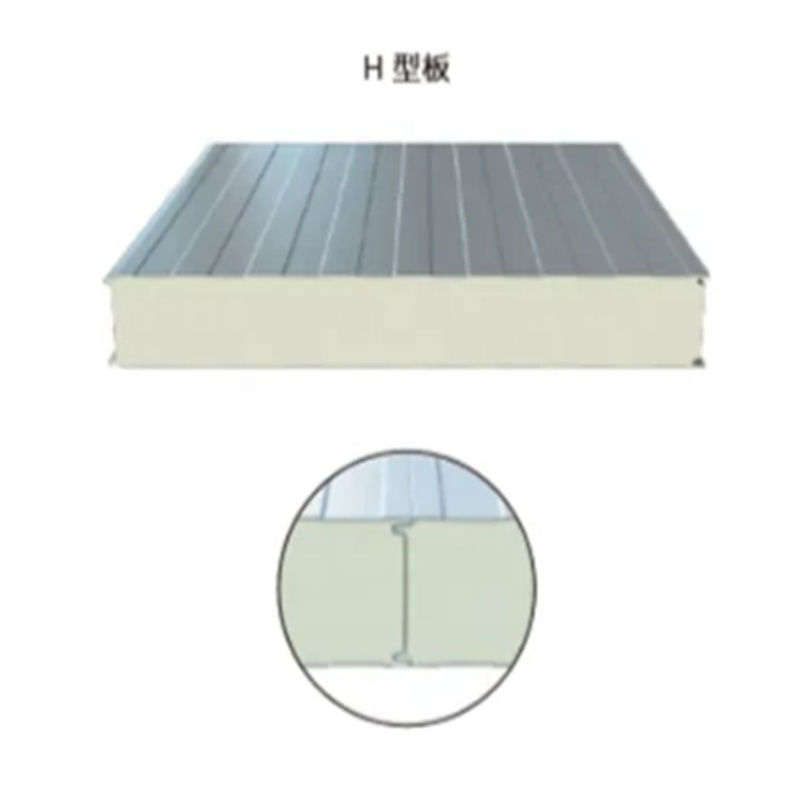

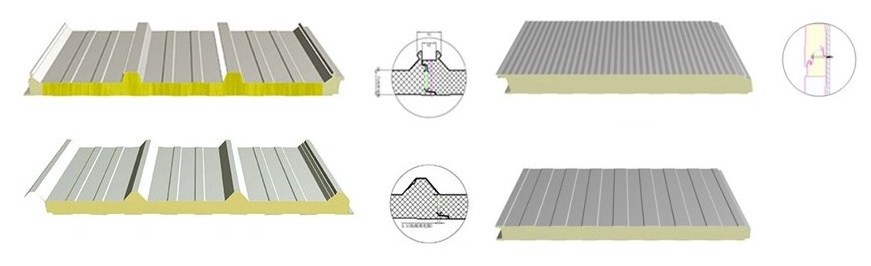

PU/PIR/PUR/PUF Sandwich Panel

|

RP-930/1000 Type

|

|

Application

|

|

|

Effective width(mm)

|

930/1000

|

Roof Panel

|

|

|

Feeding Width(mm)

|

1200(upper panel)

|

|

|

|

|

1070(inside panel)

|

|

|

|

Thickness of plate(mm)

|

0.4-0.8

|

|

|

|

Thickness of core material(mm)

|

40-150

|

|

|

|

Core material

|

PU/PIR

|

|

|

|

WP-930/1000Type

|

|

Application

|

|

|

Effective width(mm)

|

930/1000

|

Wall Panel

|

|

|

Feeding Width(mm)

|

1100(upper panel)

|

|

|

|

|

1070(inside panel)

|

|

|

|

Thickness of plate(mm)

|

0.4-0.8

|

|

|

|

Thickness of core material(mm)

|

40-200

|

|

|

|

Core material

|

PU/PIR

|

|

|

Rockwool Sandwich Panel

|

Brand of steel plates

|

Bao Steel, Yieh Phui Steel, Ma Steel, BHP Steel.

|

|

Painting of steel plates

|

PVDF, SMP, HDP, PE; The top painting should be above 25μm.

|

|

Galvanized layer of steel plates

|

Exterior plate: 55% Aluzinc above 100g/㎡ or Zinc coating above 150g/㎡;

Inner plate: 55% Aluzinc above 70g/㎡or Zinc coating above 100g/㎡. |

|

Thickness of steel plates

|

0.4mm-0.8mm.

|

|

Thickness of core

|

50mm/75mm/100mm/120mm/150mm.

|

|

Density of core

|

60/80/100/120kg/m³

|

|

Effective width

|

950/1150mm

|

|

Panel Length

|

According to customers' request

|

EPS Sandwich Panel

|

Thickness

|

50/75/100/120/150(mm)

|

|

Effective width

|

950, 980, 1150(mm)

|

|

Length

|

According to customer' s request, less than 11.8m.

|

|

Materials

|

Polystyrene foam board, Color steel tile

|

|

Structure

|

Upper and lower layer: Color steel sheet

Middle: Polystyrene foam board

|

|

The EPS density

|

8/10/12/14/15/16/18/20 kg/m³

|

|

Conventional color

|

White, sea blue, red etc.

|

|

Lifetime

|

More than 20 years

|

|

Character

|

Light weight, heat insulation, water resistant, green and environmental

|

|

Usage

|

Roof, Wall and ceiling

|

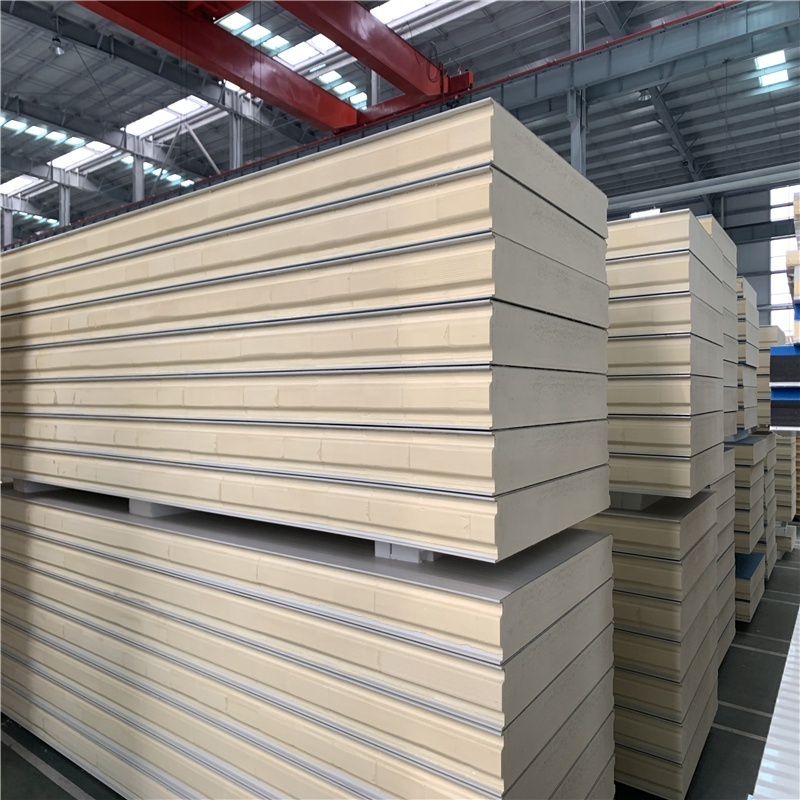

Packing & Delivery

Project Cases

Application Areas

Our Customers

FAQ

Q1: Can you offer designing service for us?

A: Yes, we have more than 50 design engineers. We could design full solution drawings as per your requirements. They use software, such as: Auto CAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures (Xsteel) V12.0. etc. We will be glad to establish sincere business cooperation with you in the near future.

Q2: Do you offer guiding service for installation on site overseas?

A: Yes. We do. We will give detailed installation drawings and video for free. And if you need, we can send guide engineers as installation director even a working team to your construction site. We have ever supplied the installation service on Australia, Cameroon, Bolivia, Chile, Angola, Gabon and etc.

Q3: How can I get your quick quotation on my project?

A: The more exhaustive your description is, the quicker our quote would be. You can chat with us at anytime via email or phone to offer us your detail information or you can just leave your message on our website. We will give you the best quotation ASAP. Thanks for your kind cooperation.

Q4: What's the procedure of trading?

A: Design drawing →Confirm drawing→Quotation→PI→ConfirmPI→Arrange 30% deposit→Manufacture→ QCinspect→ Paybalance→Shipping.

Q5: What is the biggest advantage of your product?

A: The quality of our products is better than other manufacturers. We use high-quality raw materials, strictly control the quality of production. We improve our product performance by improving our technology. These make our products more beautiful and have a longer life, lower cost of use.

A: Yes, we have more than 50 design engineers. We could design full solution drawings as per your requirements. They use software, such as: Auto CAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures (Xsteel) V12.0. etc. We will be glad to establish sincere business cooperation with you in the near future.

Q2: Do you offer guiding service for installation on site overseas?

A: Yes. We do. We will give detailed installation drawings and video for free. And if you need, we can send guide engineers as installation director even a working team to your construction site. We have ever supplied the installation service on Australia, Cameroon, Bolivia, Chile, Angola, Gabon and etc.

Q3: How can I get your quick quotation on my project?

A: The more exhaustive your description is, the quicker our quote would be. You can chat with us at anytime via email or phone to offer us your detail information or you can just leave your message on our website. We will give you the best quotation ASAP. Thanks for your kind cooperation.

Q4: What's the procedure of trading?

A: Design drawing →Confirm drawing→Quotation→PI→ConfirmPI→Arrange 30% deposit→Manufacture→ QCinspect→ Paybalance→Shipping.

Q5: What is the biggest advantage of your product?

A: The quality of our products is better than other manufacturers. We use high-quality raw materials, strictly control the quality of production. We improve our product performance by improving our technology. These make our products more beautiful and have a longer life, lower cost of use.

Hot Searches