- Product Details

- {{item.text}}

Quick Details

-

Year:

-

2022

-

Power (kW):

-

2.2 kW

-

Weight (KG):

-

3500 KG

-

Name:

-

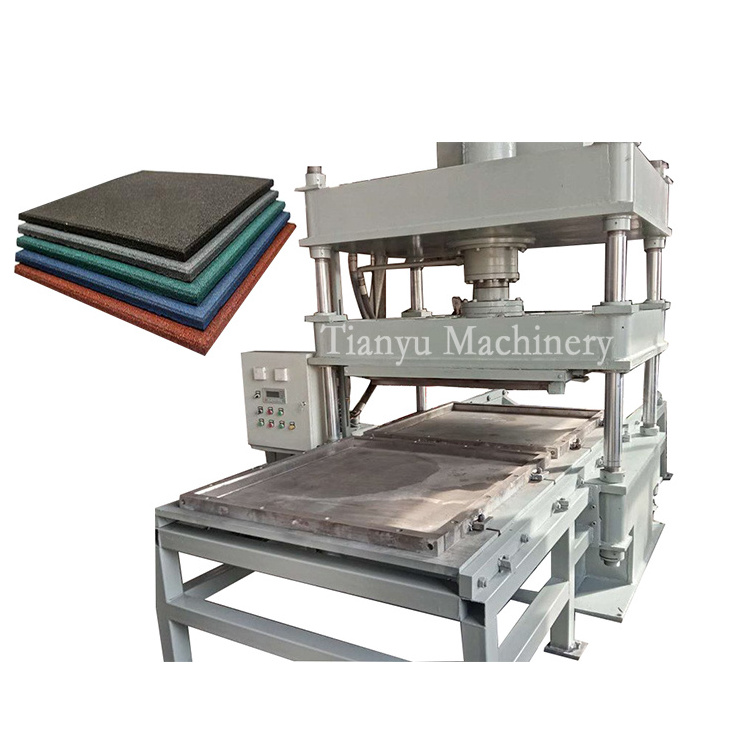

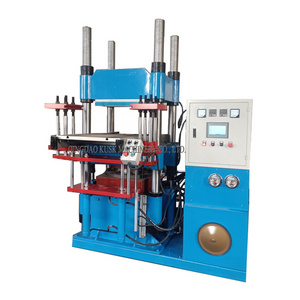

Recycled Rubber Powder into Rubber Tile Vulcanizing Machine

-

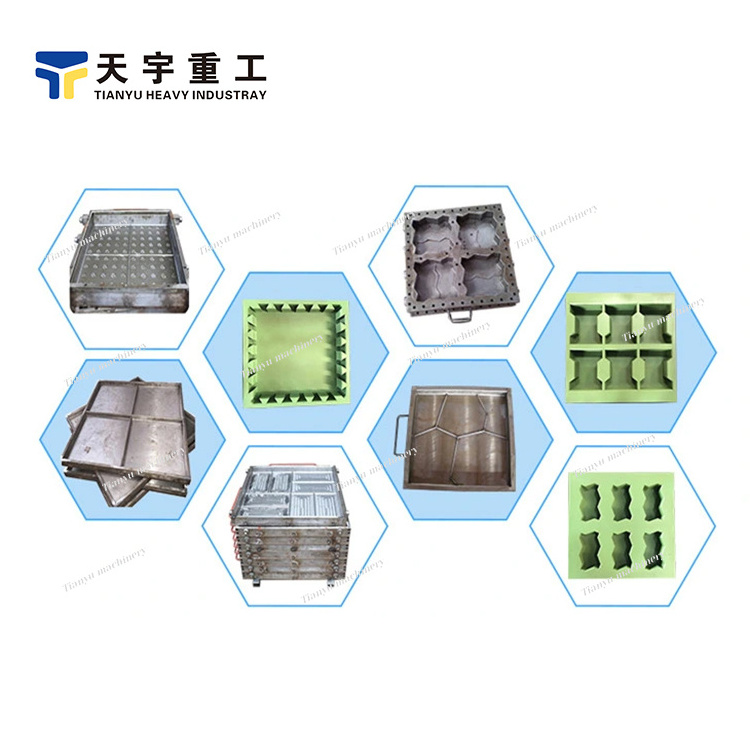

Final product size:

-

Customized

-

Raw material:

-

All kinds of rubber vulcanizing and compression molding

-

Heating method:

-

Electricity Heating

-

Working layers:

-

One, two, four or more

-

Cartridge heater:

-

Three stages winding, nichrome wire , non-rusty.

-

Advantage:

-

little noise, low vibration, no leakage, and little floor area

-

Motor:

-

Siemens, Schneider or Chinese famous brands

-

Max Temperature ( C):

-

200

-

Temperature control mode:

-

Numerical control display

-

Marketing Type:

-

New Product 2022

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Tianyu

-

Voltage:

-

220V/380V/440V or customized

-

Year:

-

2022

-

Power (kW):

-

2.2 kW

-

Weight (KG):

-

3500 KG

-

Name:

-

Recycled Rubber Powder into Rubber Tile Vulcanizing Machine

-

Final product size:

-

Customized

-

Raw material:

-

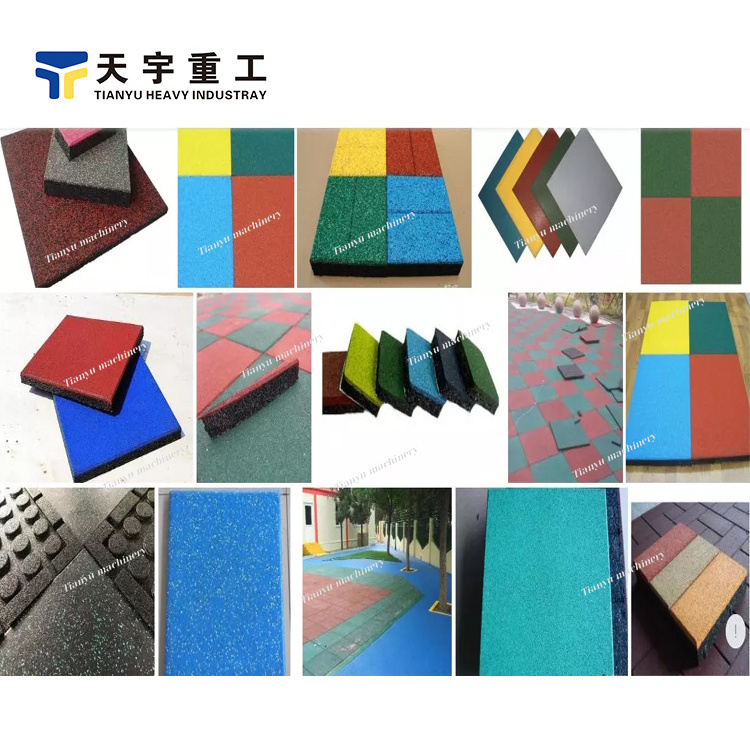

All kinds of rubber vulcanizing and compression molding

-

Heating method:

-

Electricity Heating

-

Working layers:

-

One, two, four or more

-

Cartridge heater:

-

Three stages winding, nichrome wire , non-rusty.

-

Advantage:

-

little noise, low vibration, no leakage, and little floor area

-

Motor:

-

Siemens, Schneider or Chinese famous brands

-

Max Temperature ( C):

-

200

-

Temperature control mode:

-

Numerical control display

-

Marketing Type:

-

New Product 2022

Product Overview

The Rubber Tiles Vulcanizing Machine

series has

two specifications

:

stand-alone control

and

PLC control

, which can realize

three working modes

:

manual

,

semi-automatic

and

fully automatic

. The working pressure, pressing speed and stroke range of the vulcanizing machine can be adjusted according to the needs of the process, and the operation is simple and convenient. Suitable for pressing all kinds of rubber and themosetting plastic model products and non-model products and pressing foam plastic products.

Technical Specifications

|

Parameter/model

|

TR 550x550x4

|

TR 1100x1100x1

|

|

Pressure (T)

|

50/80

|

100/120/160

|

|

Hot plate size (mm)

|

550*550*60

|

1100*1100*60

|

|

Plates Distance (mm)

|

150

|

150-300

|

|

Working layer

|

4

|

1

|

|

Hot plate quantity

|

5

|

2

|

|

Piston stroke (mm)

|

600

|

150-300

|

|

Motor power (kw)

|

2.2

|

5.5/7.5

|

|

Weight(kg)

|

3500

|

4000

|

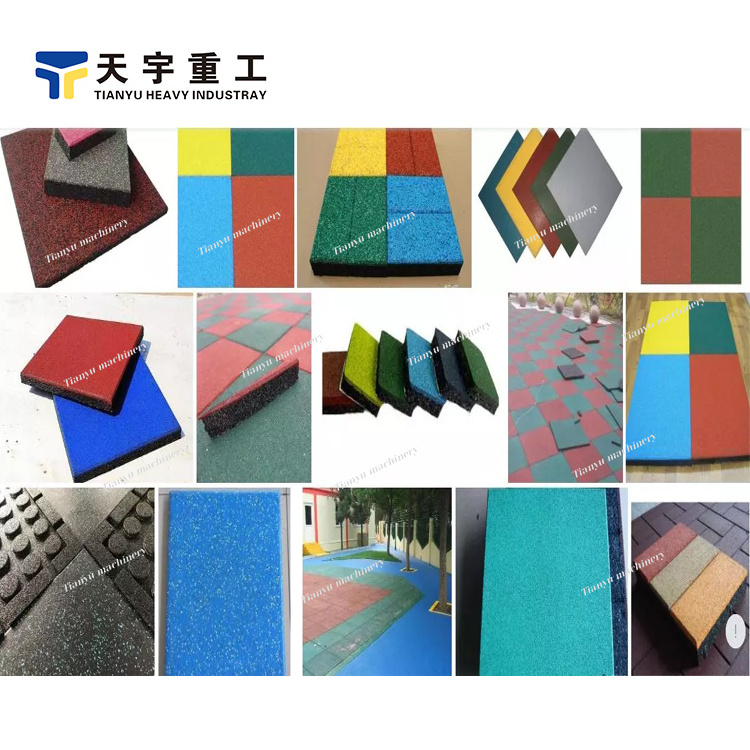

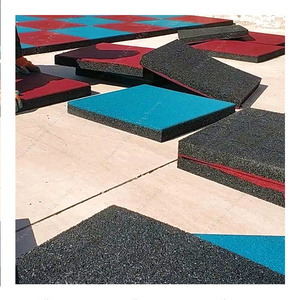

Our machine can be customized by your needs and you can provide the shape and size you want.

Mobile&Wechat&Whatsapp:

0086-18736001962

E-mail:

cilin@tian-yu.com

Technical Detail & Flow Chart

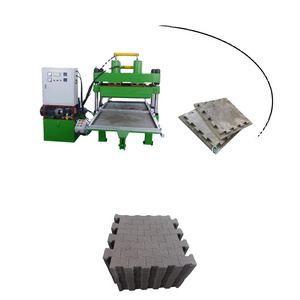

The heating forms

are divided into

three heating modes

: electric heating, steam heating, and thermal oil heating. With automatic vulcanizing machine, automatic pressure compensation, automatic alarm device

The vulcanizer hydraulic system produced by our company has a scientific design, overall rigidity, low noise, and convenient operation. It can be controlled sequentially according to the pressure, time, speed and temperature required for different products into the PLC.

The vulcanizer hydraulic system produced by our company has a scientific design, overall rigidity, low noise, and convenient operation. It can be controlled sequentially according to the pressure, time, speed and temperature required for different products into the PLC.

Secondary exhaust to improve product quality and product yield.

Feature & Advantage

1. It's downward pressing structure, easy operation for workers.

2. It can be designed to control temperature automatically, auto exhaust, auto compensation pressure, alarm at fixed time.

3. It is little noise, low vibration, no leakage, and little floor area.

4. Complete heating, molding and solidifying at one time, the finished goods can be produced between 3 to 8 minutes.

5. The mold adopts the automatic adjustable rail device to push and pull, the efficiency is very high, and

2. It can be designed to control temperature automatically, auto exhaust, auto compensation pressure, alarm at fixed time.

3. It is little noise, low vibration, no leakage, and little floor area.

4. Complete heating, molding and solidifying at one time, the finished goods can be produced between 3 to 8 minutes.

5. The mold adopts the automatic adjustable rail device to push and pull, the efficiency is very high, and

labor intensity can be reduced.

6. It can produce tiles with different thickness by one mold.

6. It can produce tiles with different thickness by one mold.

Hot Searches