- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

None

-

CrO Content (%):

-

None

-

SiC Content (%):

-

None

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

SK-34

-

Brand Name:

-

DKJL

-

Name:

-

Fire clay brick

-

Density (g/cm3):

-

2.05-2.75

-

Standard Size (mm):

-

230x114x65

-

permanent linear change % 1500CX2h:

-

-0.5%~+0.1%

-

refractoriness:

-

1740

-

cold crushing strength MPa:

-

20

-

apparent porosity:

-

24%

-

0.2 MPa refractoriness under load:

-

≥1350℃

-

Color:

-

Red fire brick

-

Application:

-

fire clay brick for industrial furnaces

Quick Details

-

SiO2 Content (%):

-

48%

-

Al2O3 Content (%):

-

35%-40%

-

MgO Content (%):

-

None

-

CaO Content (%):

-

None

-

CrO Content (%):

-

None

-

SiC Content (%):

-

None

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

SK-34

-

Brand Name:

-

DKJL

-

Name:

-

Fire clay brick

-

Density (g/cm3):

-

2.05-2.75

-

Standard Size (mm):

-

230x114x65

-

permanent linear change % 1500CX2h:

-

-0.5%~+0.1%

-

refractoriness:

-

1740

-

cold crushing strength MPa:

-

20

-

apparent porosity:

-

24%

-

0.2 MPa refractoriness under load:

-

≥1350℃

-

Color:

-

Red fire brick

-

Application:

-

fire clay brick for industrial furnaces

Wholesale Fire Clay Brick for Kiln On Sale

Fire clay bricks are mainly made from chamotte, flint clay and combining clay powder, being high pressure pressed and sintered in high temperature.

Low porosity bricks are made from low mullite stones, the main mineral composition of the low mullite stones are pressed and sintered mullite phases . The bricks have very good physical and chemical properties in high temperature conditions.

Fire clay brick Features and advantages:

1.High refractoriness,

2.High-temperature endurable.

3.Good corrosion resistance.

4.Good spalling resistance and wear resistance.

5.Good thermal shock resistance.

6.High mechanical strength.

7.High-temperature creep rate is low.

8.Good volume stability at high temperature.

Fire clay brick Application:

They are widely used in all parts of furnace lining for middle and small capacity furnace such as glass furnace, blast furnace, hot-air furnace, cement furnace,chemical furnace and other heating engineering equipment.

F ire clay brick Technical Index:

|

|

Fire Clay Brick |

Lower Porosity clay brick |

||

|

|

DK-32 |

DK-34 |

DK-15 |

DK-12 |

|

Al2O3 |

≥40 |

≥42 |

≥42 |

≥45 |

|

Refractoriness °C |

≥1710 |

≥1750 |

|

|

|

0.2MPa Refractoriness under load °C |

≥1320 |

≥1400 |

≥1470 |

≥1500 |

|

Permanent liner change% |

1350 °C×3h +0.2~-0.5 |

1400 °C×2h +0.1~-0.4 |

-0.2~+0.4 |

+0.05~-0.1 |

|

Apparent Porosity % |

≤24 |

≤22 |

≤15 |

≤12 |

|

Cold crushing strength Mpa |

≥19.6 |

≥29.4 |

58.8 |

68 |

|

Bulk Density g/cm3 |

2.1 |

2.15 |

2.3 |

2.37 |

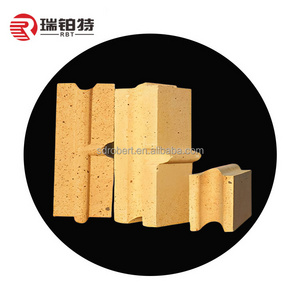

Fire clay brick Common sizes:

|

Straight type |

Arch type |

Wedge type |

|

L×W×H (mm) 230×114×65 230×114×75 230×114×32 220×110×60 220×110×50 220×110×40 220×110×30 |

L×W×H/h (mm) 230×114×65/55 230×114×65/45 230×114×65/59 220×110×65/50 220×110×75/65 220×110×60/40 |

L×W×H/h (mm) 230×114×65/55 230×114×65/45 220×110×75/65 220×110×60/40 |

|

Other sizes according to customer requirements |

||

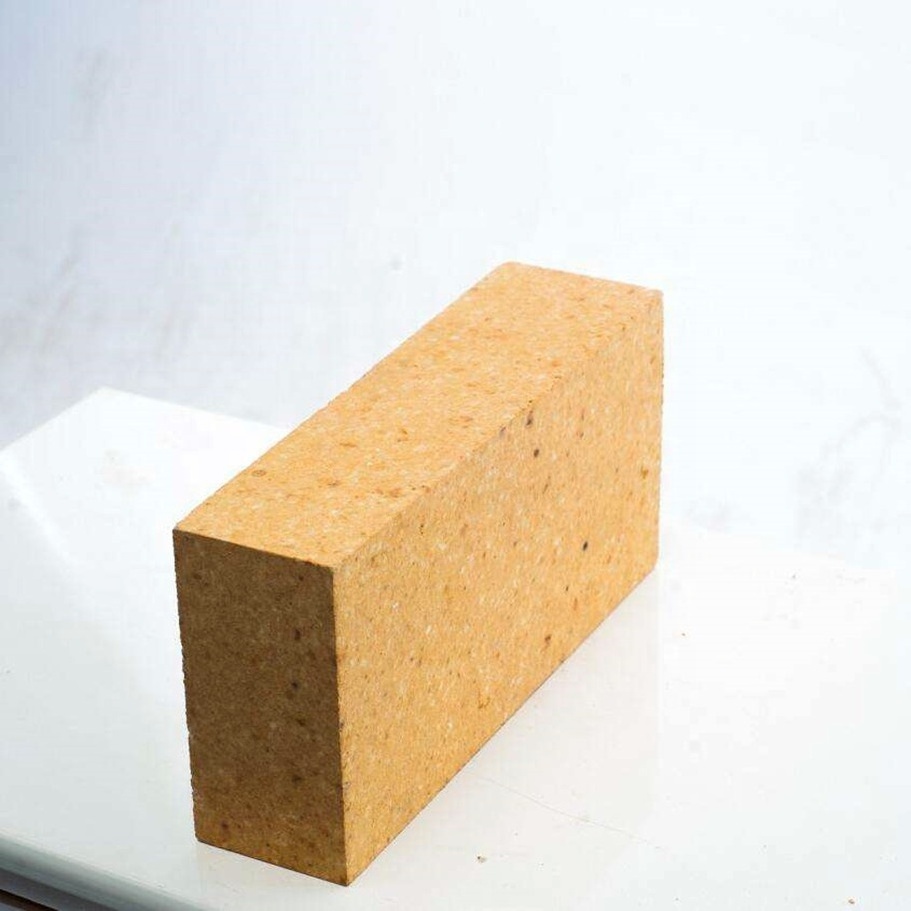

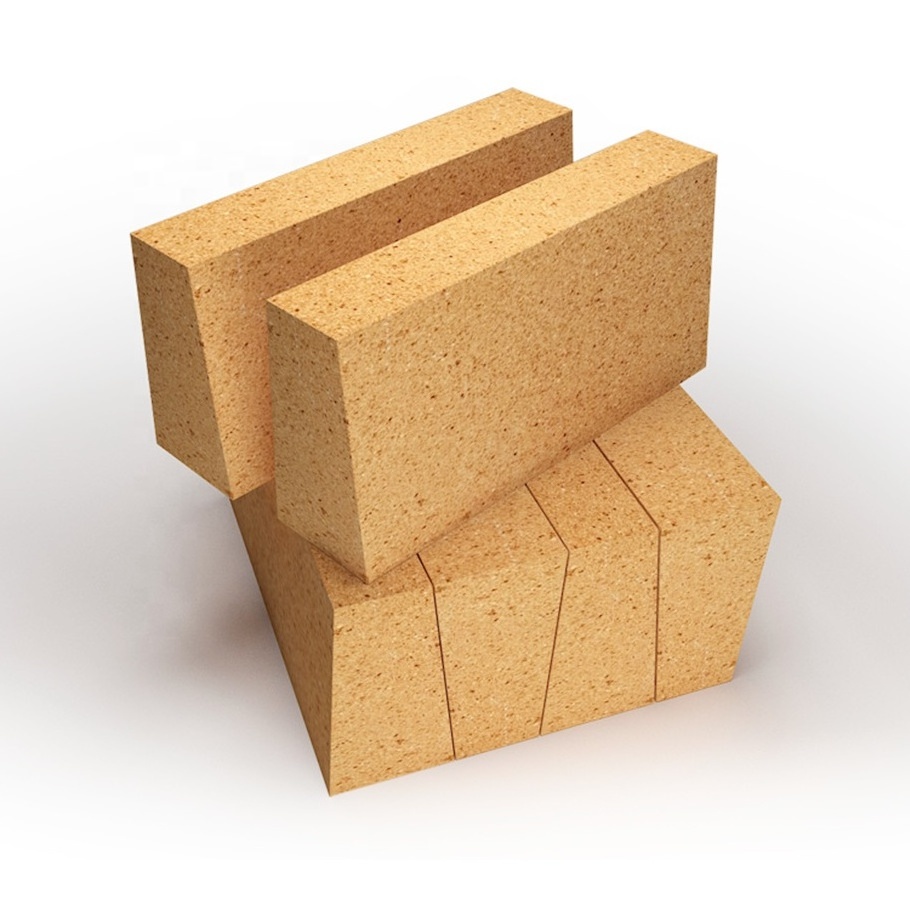

Pictures of fire clay brick

Packing of fire clay brick : Standard export wooden pallet with PET strap fixed, paper or non-woven fabrics between layers, finally wrapped with plastic shrink film from outside.

Shipping of Fire clay brick: By vessel or plane from any Chinese port

Packing pictures of fire clay brick

1.Timely response,

Timely response to your inquiry, multiple choice recommendations based on your demand,quickly respond mails and provide solutions.

2.Free sample

Fire clay brick Sample and trial order are accepted for the quality evaluation

3. Strict quality control

Arrange production on time and control quality strictly.

4.Shorter delivery time.

Book the earliest vessel or plane to guarantee the delivery time.

5.Professional Services

Provide all the detailed news and pictures from order to delivery;

Offer relative export documents and original certificate if needed;

Warm and considerable after-sale service