- Product Details

- {{item.text}}

Quick Details

-

Power:

-

See technical parameter list

-

Weight:

-

2000

-

Dimension(L*W*H):

-

See technical parameter list

-

Product name:

-

Disc Bowl Extraction Centrifuge

-

Keyword:

-

High Speed Disc Vertical Centrifuge Separator

-

Machine type:

-

Centrifugal Solid- Liquid Separator

-

Application:

-

Liquid Solid / Solid Liquid Liquid Separation

-

Feature:

-

CE Standard PLC Control

-

Operation:

-

Automatic Continuous Operation

-

Centrifugal type:

-

Disc Stack

-

Discharge type:

-

Automatic Continuous Discharge

-

Material:

-

Carbon Steel/ Stainless Steel 304/316

-

After-sales Service Provided:

-

Service Machinery Overseas

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

WINTECH

-

Voltage:

-

220V/380V/customized

-

Power:

-

See technical parameter list

-

Weight:

-

2000

-

Dimension(L*W*H):

-

See technical parameter list

-

Product name:

-

Disc Bowl Extraction Centrifuge

-

Keyword:

-

High Speed Disc Vertical Centrifuge Separator

-

Machine type:

-

Centrifugal Solid- Liquid Separator

-

Application:

-

Liquid Solid / Solid Liquid Liquid Separation

-

Feature:

-

CE Standard PLC Control

-

Operation:

-

Automatic Continuous Operation

-

Centrifugal type:

-

Disc Stack

-

Discharge type:

-

Automatic Continuous Discharge

-

Material:

-

Carbon Steel/ Stainless Steel 304/316

-

After-sales Service Provided:

-

Service Machinery Overseas

High Speed Automatic Continuous Flow Fruit Juice Disc Bowl Extraction Centrifuge

Products Description

Our Customer Factory:Beer Yeast Separation

Our

Customer Factory:Dairy Milk Separation

Our Customer Factory:Animal and Vegetable Oil

Separation

Brief Introduction:

Disc centrifuge is a kind of vertical centrifuge. The drum is installed on the upper end of the vertical shaft, and is driven by motor through the transmission device to rotate at high speed. Inside the drum there is a set of disc-shaped parts which are overlapped with each other. Inside the drum is a set of disc-shaped parts, which are nested and folded together. There is a small gap between the discs. The suspension (or emulsion) is added to the drum by the feed pipe at the center of the drum. When the

suspension (or emulsion) flows through the gap between the discs, the solid particles (or droplets) settle on the discs under the action of the centrifuge to form sediment (or liquid layer). The sediment slides along the surface of the disc and separates from the disc and accumulates in the place with the largest inner diameter of the drum. The separated liquid is discharged from the outlet of the drum. The function of the disc is to shorten the settling distance of solid particles (or droplets) and expand the settling area of the drum. The disc installed in the drum greatly improves the production capacity of the separator. The solid accumulated in the drum shall be removed manually after the separator is shut down, or discharged from the drum without shut down through the slag removal mechanism.

Working Principle:

The materials are transmitted to the heart parts of this machine, the inside of the drum. Under the action of strong centrifugal force, the materials (mixed liquid) pass through the intervals of a group of disk pieces bundles, and then, regarding the neutral hole of the disk pieces as the interface, the liquid with higher density (heavy phase) moves outward the neutral hole along the disk pieces, among which, the heavy residues accumulate in the sediment area, and the heavy phase flows to the large centripetal

pump. The liquid with lower density (light phase) moves inward and upward along the disk pieces wall and gathers in the small centripetal pump. The heavy phase and light phase output by the large centripetal pump and small centripetal pump respectively.

Model Selection:

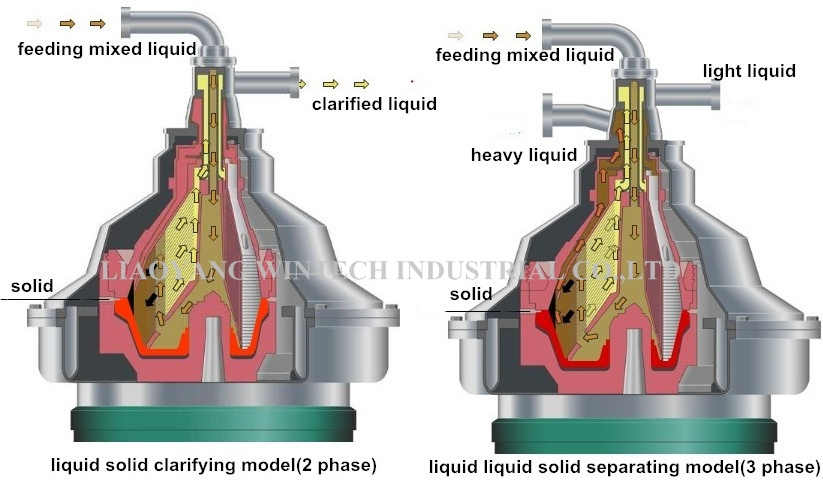

1. Two phase:

Liquid solid separation (i.e. separation of bottom concentration suspension), which is called clarification operation, that is two-phase separation.

2. Three phase:

Liquid-liquid separation (or liquid-liquid-solid) separation (i.e., the separation of emulsion) is called separation operation, that is three-phase separation.

The disc separator is specially used for the two-phase and three- phase separation. The two-phase separation is to separate the suspended solid from liquid or two liquids which have the different specific gravity and are immiscible. The three-phase separation is to separate the two immiscible liquid phases and a phase of solid at the same time. This automatic discharging separator has the traits as high rotating speed, operating stability, completely sealed up of the inlet and outlet system, lower

noise and fine separating effect. Centripetal pump system designed by our professional designer has the traits as stable outlet pressure, large regulating sphere and operating easily. It has professional automatic domination case with safety protection device and advanced automatic vibrating testing instrument which can view vibrating number at any time. We can make the best separating and discharging by adjusting separating parameter directly at the screen.

Advantages:

1.) High speed, stable operation, all import and export systems are sealed, noise is low, and separation effect is good.

2.) The professionally designed centripetal pump system has stable output pressure, large adjustment range and convenient operation.

3.) The drum has a special structure, which has a large processing capacity and good degreasing and clarifying effect.

4.) Professionally designed automatic control cabinet, can observe the vibration value of the equipment at any time.

2.) The professionally designed centripetal pump system has stable output pressure, large adjustment range and convenient operation.

3.) The drum has a special structure, which has a large processing capacity and good degreasing and clarifying effect.

4.) Professionally designed automatic control cabinet, can observe the vibration value of the equipment at any time.

Product More Pictures

Product Parameters

|

We have many different models to choose from. If you can't confirm which model is suitable for your project, please feel free to contact us and let us know your requirements, and then we will recommend the suitable model to you.

|

|

|

|

|

||||

Application Field

1. Mineral Oil Industry:

marine engine, land diesel engine, power station and other fuel oil and lubricating oil purification;

2. Dairy Industry:

clarification, purification and degreasing of fresh milk;

3. Vegetable Oil Industry:

purification and clarification of palm oil, refining and degumming of vegetable oil, de soap, dehydration and sodium removal, etc;

4. Beverage Industry:

clarification of beer, juice and beverage, clarification of bioengineering fermentation broth such as extraction of plant protein and wastewater treatment;

5. Chemical Industry:

purification or clarification of chemical raw materials.

Product Packaging

Hot Searches