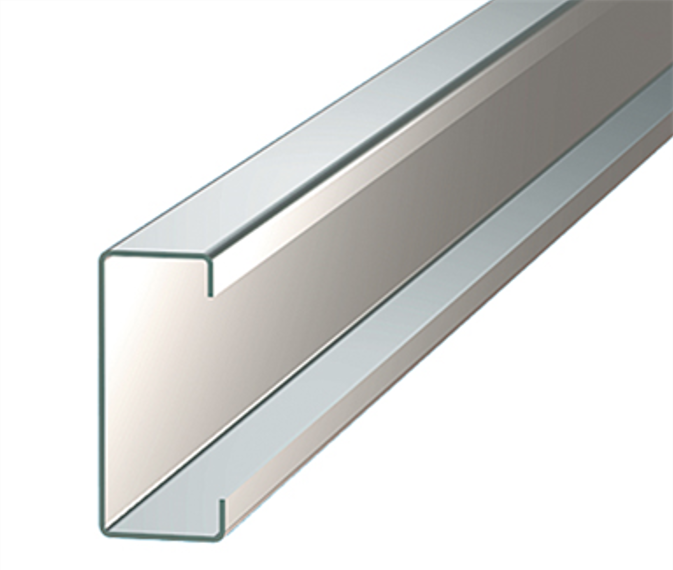

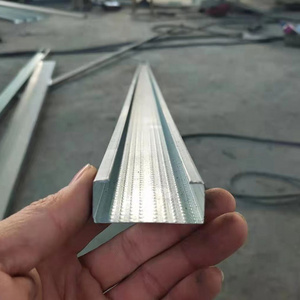

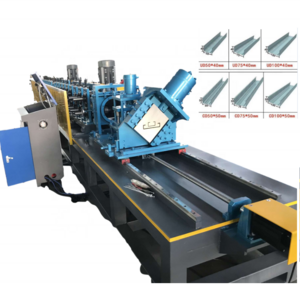

C purlin roll forming machine is an equipment that produces C shaped steel channels continuously out of galvanized or cold rolled steel strips from feeding, punching for holes, bending and cutting.

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Demma

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

350cm * 90cm * 120cm

-

Weight:

-

1500 kg

-

Marketing Type:

-

New Product

-

Name:

-

Steel Purlin Roll Forming Machine

-

Usage:

-

Roof Ridge Cap

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Roller stations:

-

13 Stations

-

Control system:

-

PLC(imported Brand)

-

Main frame:

-

300-450 H steel

-

Decoiler:

-

5T Manual Decoiler

-

Profiles:

-

Cold Roll Forming Machine

-

Certification:

-

CE ISO

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

30 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Demma

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

350cm * 90cm * 120cm

-

Weight:

-

1500 kg

-

Marketing Type:

-

New Product

-

Name:

-

Steel Purlin Roll Forming Machine

-

Usage:

-

Roof Ridge Cap

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Roller stations:

-

13 Stations

-

Control system:

-

PLC(imported Brand)

-

Main frame:

-

300-450 H steel

-

Decoiler:

-

5T Manual Decoiler

-

Profiles:

-

Cold Roll Forming Machine

-

Certification:

-

CE ISO

Galvanized Cold Rolled Steel C Shaped Steel Channels Roll Forming Machine Light Gauge Steel Frame Roll Forming Machines

Send me an inquiry now for more discounts! !

Product Description

Steel Purlin Roll Forming Machine

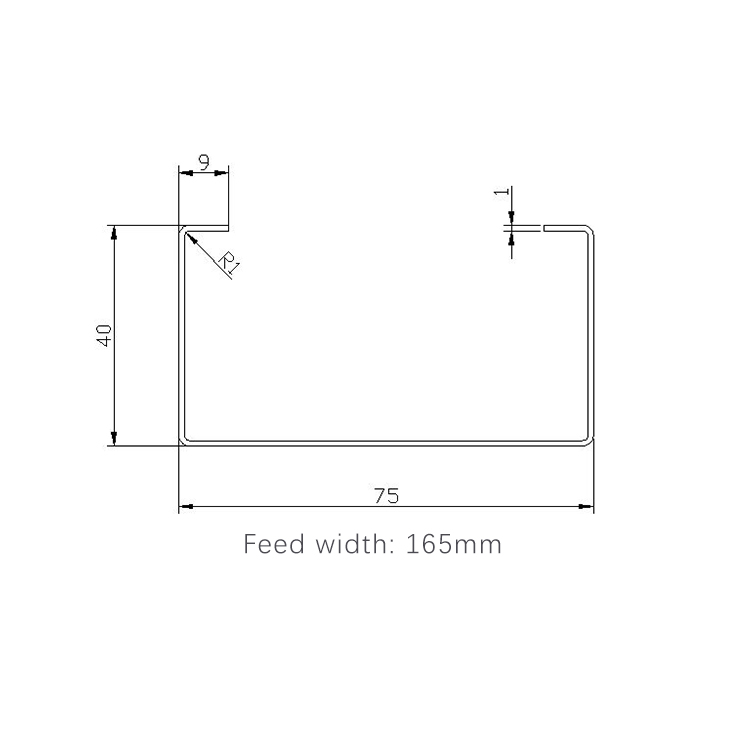

Specification

Galvanized Cold Rolled Steel C Shaped Steel Channels Roll Forming Machine Light Gauge Steel Frame Roll Forming Machines

We customize the machine according to customer's requirements and can be used for a wide variety of profiles.

|

Total power

|

3.7 – 15kw

|

|

Speed

|

12- 15m/min

|

|

Dimension (LxWxH)

|

(6-8)x(1.0-1.4)x1.4m

|

|

Weight of machine

|

3 – 12 tons

|

|

Roller station

|

08 – 20

|

|

Material thickness

|

0.15 – 0.5mm (G300-G550)

|

|

Material width

|

150 – 450mm

|

Details of roll forming machine:

Configuration is not unique, we will customize a number of program for you, to provide you with more options.

Control system:

Language:English, Chinese,Spanish and Russian.

The system is easy to operate and use.

Material of the roller : High grade No.45 forged steel.

Roller station : 12-14 rows.

Thickness of feeding material : 0.3-0.8mm

Electric type guillotine;

Knife made of steel;

Automatic activation;

Detail Images

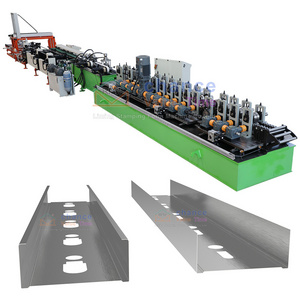

TECHNICAL FLOW PROCESS

The picture shows the whole process of cold roll forming machine :

The machine is fully automatic and it is easy to operate with a friendly HMI panel. It consists of one decoiler, sheet guiding

equipment, roll forming section, PLC control system, Hydraulic cutting, collection table.

Shipping & Delivery

1.All export goods will be packed according to customer requirements before shipment and used in roof sheet roll forming machine.

2.Before the goods arrived destination port, we will provide customer bill of lading and clearance documents for making clearance customs.

Hot Searches