- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Customized

-

Shape:

-

Customized

-

Material:

-

Stellite alloy, Stellite alloy

-

Chemical Composition:

-

co.cr.w

-

Product name:

-

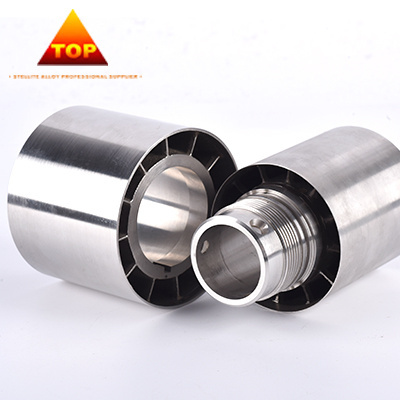

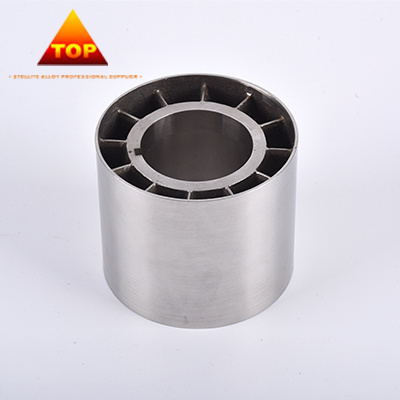

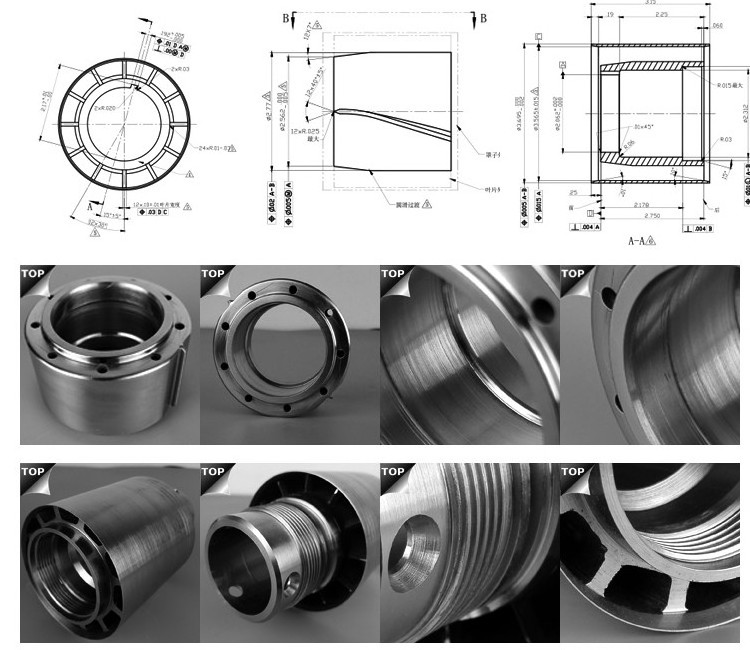

CoCrW alloy gyrocopter rotor head used on rotor spinning machine

-

Casting process:

-

Investment casting

-

Keyword:

-

Rotor and stator

-

Specifications:

-

Acc. to customer's demands

-

Dimensions:

-

Customized

-

OEM:

-

Acceptable

-

Service:

-

24/7

-

Surface treatment:

-

Machined

Quick Details

-

Application:

-

Oil and gas drilling industry, Oil and gas drilling industry

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

SYTOP

-

Model Number:

-

Customized

-

Shape:

-

Customized

-

Material:

-

Stellite alloy, Stellite alloy

-

Chemical Composition:

-

co.cr.w

-

Product name:

-

CoCrW alloy gyrocopter rotor head used on rotor spinning machine

-

Casting process:

-

Investment casting

-

Keyword:

-

Rotor and stator

-

Specifications:

-

Acc. to customer's demands

-

Dimensions:

-

Customized

-

OEM:

-

Acceptable

-

Service:

-

24/7

-

Surface treatment:

-

Machined

CoCrW alloy gyrocopter rotor head used on rotor spinning machine

Materials of rotor and stator-- Cobalt Chrome Stellite Alloy

---Excellent wear and corrosion resistance even at high temperature up to 800℃

SYTOP cobalt base alloys is a range of cobalt-chromium-tungsten alloys with wear resistance, corrosion and high thermal resistance. It is widely used in oil & gas, machinery, wood cutting, automotive, paper and food processing industry etc .

Chemical compositions and properties (%)

|

Brand |

C |

Mn |

Si |

Cr |

Ni |

Mo |

W |

Co |

Fe |

P |

S |

Density (g/cm3) |

Hardness (HRC) |

|

TOPS 3 |

2.0-2.7 |

1.0 |

1.0 |

29-33 |

3.0 |

|

11-14 |

Bal. |

3.0 |

≤ 0.03 |

≤ 0.03 |

8.55 |

51-55 |

|

TOPS 6 |

0.9-1.4 |

1.0 |

1.5 |

27-31 |

3.0 |

1.5 |

3.5-5.5 |

Bal. |

3.0 |

≤ 0.03 |

≤ 0.03 |

8.35 |

38-44 |

|

TOPS 12 |

1.1-1.7 |

1.0 |

1.0 |

28-32 |

3.0 |

|

7.0-9.5 |

Bal. |

3.0 |

≤ 0.03 |

≤ 0.03 |

8.40 |

44-49 |

|

TOPS 20 |

2.2-3.0 |

|

2.0 |

30-34 |

3.0 |

1.0 |

14-18 |

Bal. |

3.0 |

≤ 0.05 |

≤ 0.05 |

8.65 |

53-59 |

|

TTG 25 |

2.2-2.8 |

1-3 |

|

27-32 |

7 |

Ta/Nb |

14-19 |

Bal. |

2-5 |

|

|

8.84 |

57-60 |

|

TTG 35 |

3.3-3.8 |

1-3 |

|

27-32 |

7 |

Ta/Nb |

14-19 |

Bal. |

2-5 |

|

|

8.80 |

60-63 |

|

T400 |

0.04 |

|

2.5-2.7 |

8-10 |

|

27-29 |

|

Bal. |

|

|

|

|

55 |

|

T800 |

0.04 |

|

3.2-3.6 |

16-18 |

|

27-29 |

|

Bal. |

|

|

|

|

58 |