- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Haide

-

Voltage:

-

380v/3phase/50hz

-

Dimension(L*W*H):

-

3500*600*900mm

-

Weight:

-

1000 kg

-

Feeding width:

-

100-150mm

-

Marketing Type:

-

New Product 2021

-

Certification:

-

CE

-

Shaft:

-

40mm

-

Roller steps:

-

12

-

Main structure:

-

Groove steel

-

Control system:

-

Fully automatic

-

cutting:

-

fly cutter

-

PLC:

-

Delta

-

Main motor:

-

2.2KW

-

color:

-

as your need

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

8-12m/min

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Haide

-

Voltage:

-

380v/3phase/50hz

-

Dimension(L*W*H):

-

3500*600*900mm

-

Weight:

-

1000 kg

-

Feeding width:

-

100-150mm

-

Marketing Type:

-

New Product 2021

-

Certification:

-

CE

-

Shaft:

-

40mm

-

Roller steps:

-

12

-

Main structure:

-

Groove steel

-

Control system:

-

Fully automatic

-

cutting:

-

fly cutter

-

PLC:

-

Delta

-

Main motor:

-

2.2KW

-

color:

-

as your need

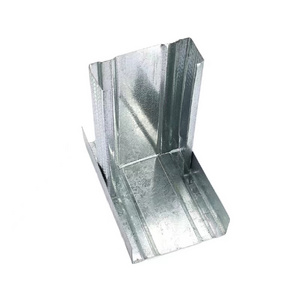

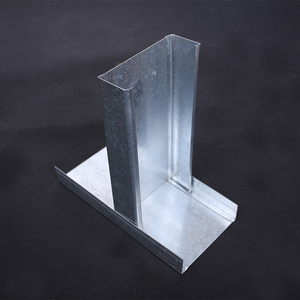

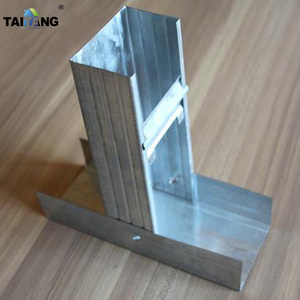

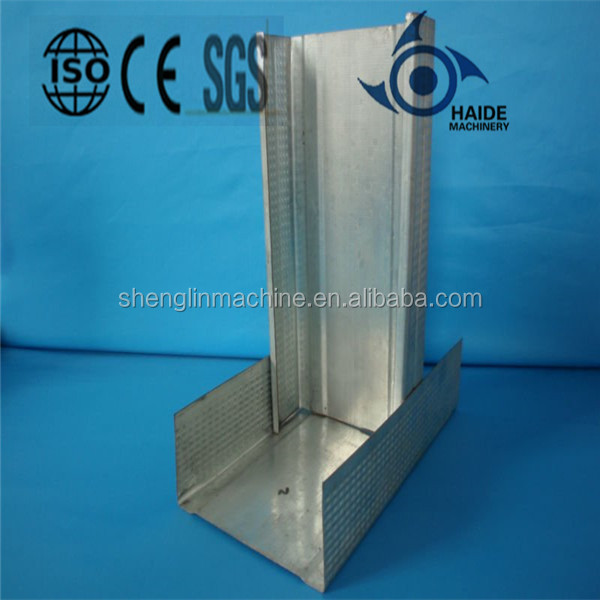

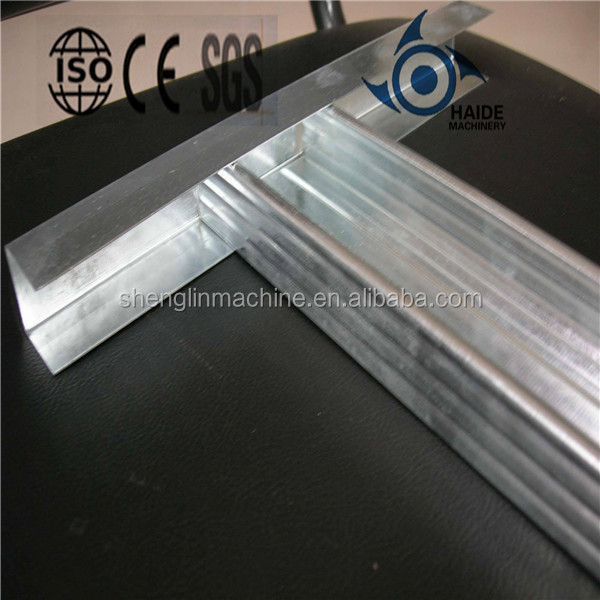

Stud and track roll forming machine for ceiling

1 This roll forming machine can roll forming

fastening gypsum plaster board

. After roll formed by this roll forming machine, the surface will be very smooth and beautiful without any scratch on surface.

2 we also can do a custom roll forming machine, We can design the machine according to your specification and profile drawing.

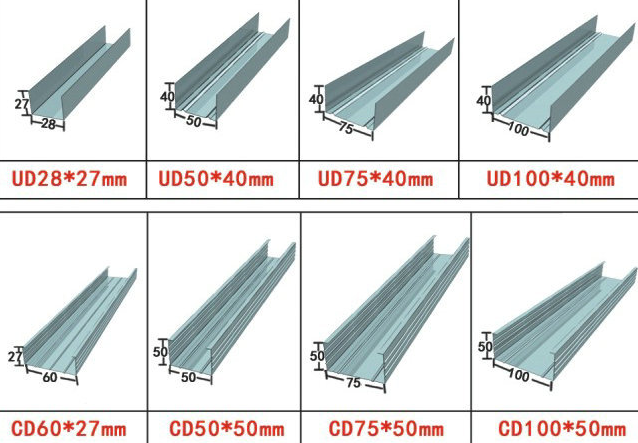

3 One roll forming machine only can produce one profile. The following profile drawing are some examples for your

reference.

Sizes available

PS: all sizes above are changable, just tell us your desired sizes and we deisign machine for you.

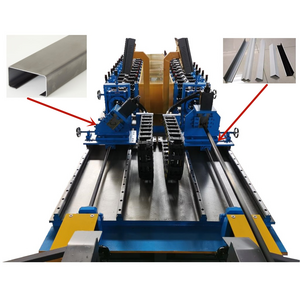

B Machine parameters

|

Performances |

Parameters |

|

|

Suitable material |

Zinc coated sheet or galvanized coil or colored coil |

|

|

Suitable material |

Feeding width 120mm thickness 0.55 mm |

|

|

Productivity |

6 -12m/min |

|

|

Roller forming steps |

1 2 steps forming |

|

|

Roller material |

Bearing steel with quenched treatment 55-60°C |

|

|

Diameter of active shaft |

φ 40mm |

|

|

Main machine body |

thick groove steel welded structure |

|

|

Power |

5.5KW +3 KWmotor |

|

|

Shear |

Electromechanical guillotine shears

|

|

|

Transmission |

Gear and chain |

|

|

Voltage |

AC380V / 50HZ / 3 phase |

|

|

Size (length*width*height) |

3500*600*900MM |

|

|

Component |

Uncoiler-forming part-hydraulic shear-set off table |

|

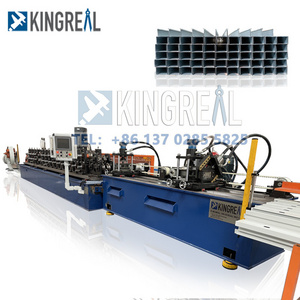

C Machine components line

Driven uncoiler

Roll forming mill (7 stands)

Electromechanical guillotine shears

Automated control system