- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

19000*2000*1500mm

-

Warranty:

-

2 Years

-

Weight:

-

7 tons

-

Power:

-

75 KW

-

Name:

-

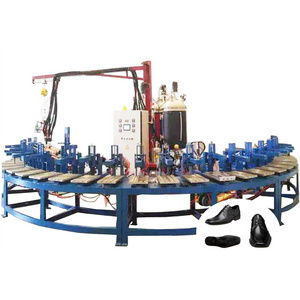

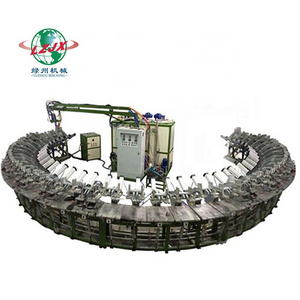

PU Foam Shoe Sole Machine Manufacturing Machinery

-

Type:

-

PU pouring machine

-

Finished Products:

-

PU Insoles, Outsoles

-

Workstations:

-

40/60/80/100/120 Stations for choose

-

Production Capacity:

-

300-400 Pairs per hour

-

Container:

-

40 feet

-

Material:

-

PU

-

Labor:

-

6-9 Workers

-

Tanks:

-

3 Pieces

-

Tank capacity:

-

120L

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Kingstone

-

Model Number:

-

JL-298

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

19000*2000*1500mm

-

Warranty:

-

2 Years

-

Weight:

-

7 tons

-

Power:

-

75 KW

-

Name:

-

PU Foam Shoe Sole Machine Manufacturing Machinery

-

Type:

-

PU pouring machine

-

Finished Products:

-

PU Insoles, Outsoles

-

Workstations:

-

40/60/80/100/120 Stations for choose

-

Production Capacity:

-

300-400 Pairs per hour

-

Container:

-

40 feet

-

Material:

-

PU

-

Labor:

-

6-9 Workers

-

Tanks:

-

3 Pieces

-

Tank capacity:

-

120L

PU Foam Shoe Sole Machine Manufacturing Machinery JL-298

|

Specifications |

|

||

|

Machine model |

JL-298 |

||

|

Tank quantity |

|

3 |

|

|

Tank capacity |

L |

120/160/250 |

|

|

Metering pump quantity |

|

3 |

|

|

Metering pump speed |

rpm |

0-280 |

|

|

Rotating speed of pouring nozzle |

rpm |

8600 |

|

|

Cleaing of pouring nozzle |

|

Manual/Auto |

|

|

Measure precision |

|

±0.5 |

|

|

Max.pouring volume |

G/S |

90 |

|

|

Rated voltage |

V |

3 phase 220/380 |

|

|

Power |

KW |

23 |

|

|

Specifications of Moulding Conveyor |

|||

|

Work stations |

Stations |

60/80/100 |

|

|

Speed adjustment range of mould table |

M/min |

0-20 |

|

|

Mould table dimension |

mm |

600*500/500*500 |

|

|

Metering pump speed |

rpm |

0-280 |

|

|

Rotating speed of pouring nozzle |

rpm |

8600 |

|

|

Heating Mode |

|

Electricity/oil |

|

|

Power |

KW |

Electricity 36/49.5/61.5

|

|

|

Dimension |

MM |

19000/25000/30000*2000*1500 |

|

|

*Note: Above data only for reference. |

|||

1.

This machine can make 2 colour,2 density PU shoe sole.

2.

It has 3 raw material tanks,2 A tank and 1 B tank, can make different colour and different density PU foaming shoe sole, by mix each A and B tank under customer’s requirement.

3.

Machine is controlled by PLC system, automatic adjustment for raw material ratio, metering pump speed, temperature setting of material and control mode of Pressure.

4.

It adopts needle-valve mixed nozzle, rotating speed can reach 8600 rpm.

saving material, decrease wash times, increase productivity, improve product quality and reduce production cost.

5.

Raw material tank has double layer heat preservation, ensure the material in constant temperature during production which will save energy and power.

6. Electric heating system makes the heating faster and better.

The machine can produce insoles and outsoles, can widely used for sports shoes, leather shoes, safety shoes, sandals, etc.