- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

metal mold

-

Product Name:

-

Die

-

Type:

-

CNC Process

-

Application:

-

punching mold

-

Mould material:

-

P20/718/738/NAK80/S136

-

Design software:

-

CAD

-

Color:

-

White

-

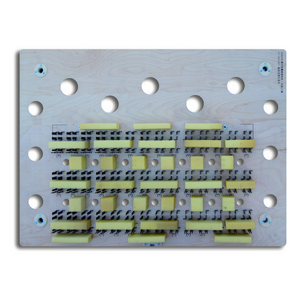

Cavity:

-

1 cavity/2 Cavities

-

Size:

-

Customer Size Accepted

-

Delivery Time:

-

25-40days

-

Certification:

-

CE

Quick Details

-

Shaping Mode:

-

Punching Mold

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BESCO

-

Model Number:

-

metal mold

-

Product Name:

-

Die

-

Type:

-

CNC Process

-

Application:

-

punching mold

-

Mould material:

-

P20/718/738/NAK80/S136

-

Design software:

-

CAD

-

Color:

-

White

-

Cavity:

-

1 cavity/2 Cavities

-

Size:

-

Customer Size Accepted

-

Delivery Time:

-

25-40days

-

Certification:

-

CE

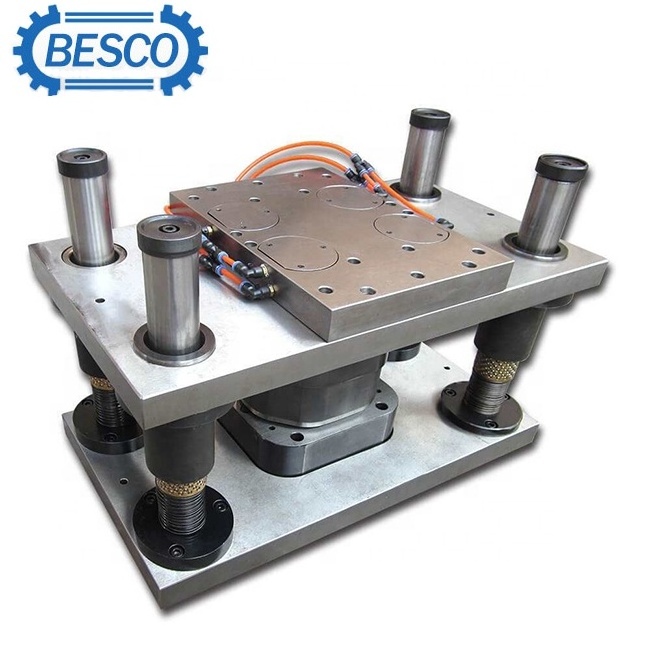

Product Application

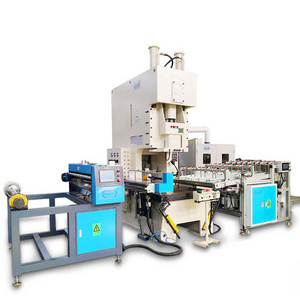

1) Equipment: We own Stamping machines, Hydraulic press machines, Auto-Turning machines, CNC-Turning machines, Milling machines, Precision wire cutting machines, more than 160 sets in total;

2) Material: iron, carbon steel, stainless steel, brass, copper, alloy steel, aluminum, cold rolled steel with various plating;

3) Surface treatment: kinds of plating (Zinc, Nikel, Chrome, Tin, Ag); Painting, Powder, Anodizing, E-coating, Silkscreen, Heat treatment, Black oxid

4) Standard/ specification: OEM service as per customers' requests, within-house tooling design & fabricating;

5) RoHS compliance for export

6) Quality assurance in accordance with ISO9001:2008

7) Concurrent engineering capability on product design

8) Just-in-time manufacturing capability to meet customer's requirement

9) Tailor-made packaging method according to customer's requirement

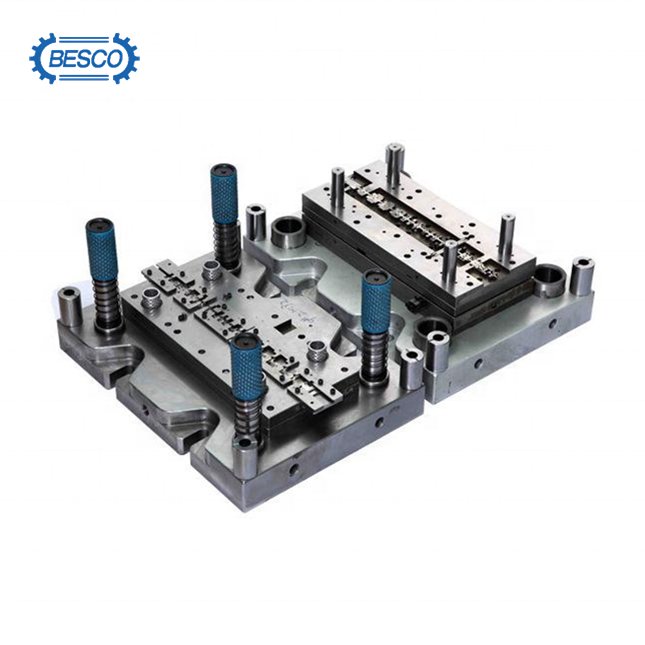

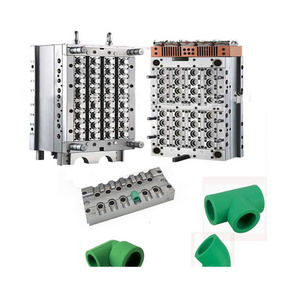

Mold

|

Product Name

|

power press dies/mould

|

|

Material of Die

|

D2, SKH-9, SKD11, A3,SKD61 etc.

|

|

Design Software

|

AutoCAD, PRO/E

|

|

Die Type

|

Stamping press moulds , stamping die, punching die, sheet metal mould , progressivedie, terminal die,single die, double die or according to your parts

|

|

Drawing format

|

igs,stp, prt, asm, pdf, dwg, dxf

|

|

Die Life

|

1,000,000-3,000,000 shots

|

|

First Trial

|

15-25 days after mold drawing confirmed

|

|

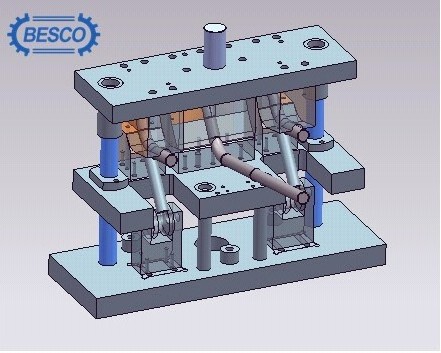

Mould design

|

Design the mould structure drawing according to your product drawing or sample,

then send to you for confirmation.

|

|

Quality confirm

|

You will confirm our stamping die quality according to sample.

If you need to adjust the product structure, we can help you to change it further.

|

|

Delivery

|

Ship the stamping die after it is completely OK, packed by wooden case.

And together with mould, mould detailed drawing, mould label will be also delivered.

|

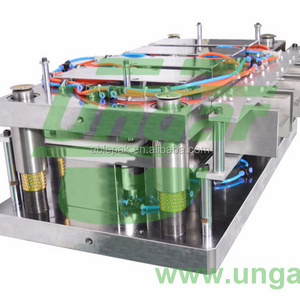

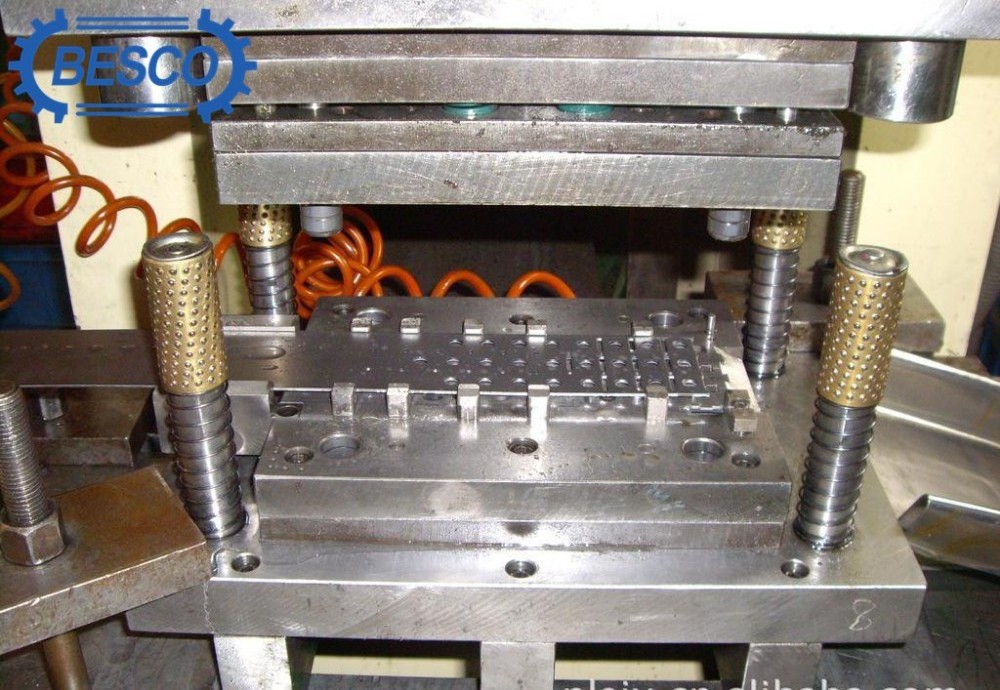

Main Features

1.Moulds are made by high quality steel which ensure mould has a long using life.

2. Moulds adopts pneumatic rebound device which makes the mould more flexible.

3.We can print customer's preferred logos upon request.

4.Consummate quality system, smooth wall container, multi-cavity container, various rims and multi-compartment.

5.Advanced assistant designing system(PRE/CAD/CAE/CAM) in the mould designing

6.Vacuum heat treatment.The mould adopts aeroelasticity resillience device,stable quality, high precision and reasonable design.

7.The mould can realize the process of cutting,forming, plugging and rolling of aluminum foil wares in one step.

Pre-Sales Service

* Technical solution

* Online video authentication machine work.

* Cutting samples provided by Business express

After-Sales Service

* Supplier will provide detail manual for software, hardware and trouble shooting, also supplier should give necessary guidance online if Buyer need. If it's necessary, Buyer should send regular his technical staff to Supplier for technical training.

|

Packaging

|

|

|

|

Size

|

800mm*500mm*400mm

|

|

|

Weight

|

200KG

|

|

|

Packaging Details

|

|

|

Q: How long is your delivery time?

A: That depend on the stocks.

Q: What is your terms of payment ?

A: Payment<=1000 USD, 100% in advance. Payment>=1000 USD, 30% T/T in advance ,balance before shipment.

If you have another question, please feel free to contact us as below:

Aluminum foil container making machine

99.3% Response Rate

All-in-one tubesheet machine

95.7% Response Rate

Pipe hole punching machine

97.6% Response Rate