- Product Details

- {{item.text}}

Quick Details

-

Year:

-

2024

-

Voltage:

-

380V/220V Optional

-

Dimension(L*W*H):

-

1740*810*1830mm

-

Motor Power (kW):

-

5.5

-

Weight (T):

-

1.8

-

Product name:

-

Hydraulic combined punching and shearing machine

-

Keyword:

-

iron worker

-

Function:

-

punching and shearing cutting

-

Usage:

-

Pressing Metal Products

-

Video outgoing-inspection:

-

Provided

-

Core Components:

-

Bearing

-

Punching press:

-

60T

-

Material:

-

Metal

-

Type:

-

Multi-Function Machine

-

Machine Type:

-

Hydraulic Ironworker

Quick Details

-

Nominal Force (kN):

-

600

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

CNCColgar

-

Year:

-

2024

-

Voltage:

-

380V/220V Optional

-

Dimension(L*W*H):

-

1740*810*1830mm

-

Motor Power (kW):

-

5.5

-

Weight (T):

-

1.8

-

Product name:

-

Hydraulic combined punching and shearing machine

-

Keyword:

-

iron worker

-

Function:

-

punching and shearing cutting

-

Usage:

-

Pressing Metal Products

-

Video outgoing-inspection:

-

Provided

-

Core Components:

-

Bearing

-

Punching press:

-

60T

-

Material:

-

Metal

-

Type:

-

Multi-Function Machine

-

Machine Type:

-

Hydraulic Ironworker

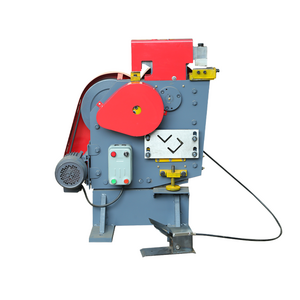

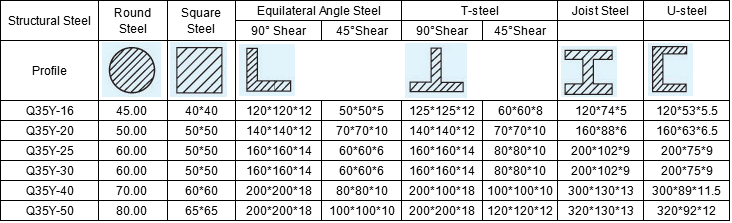

Products Description

|

Q35y-25 Hydraulic Punch Machine and Ironworker

|

|

|

|

|

||||

1. Robust and accurate steel frame

2. Large punch table with scales

3. Removable bolster for punching flanges and channel and beam

4. 2 independent hydraulic cylinders

4. 2 independent hydraulic cylinders

5. 2 shielded foot controls

6. 2 Separate Die Openings for over sized punching

7. 5 working stations for wide applications

8. power inching on all 5 work stations

9. plate shear support table and notching table

10.adjustable stroke controls with indicators on both cylinders

11. punching machine: Movable work light

12. overload protection on hydraulic system

13. electric back gauge

14. optional bending attachment

Details Images

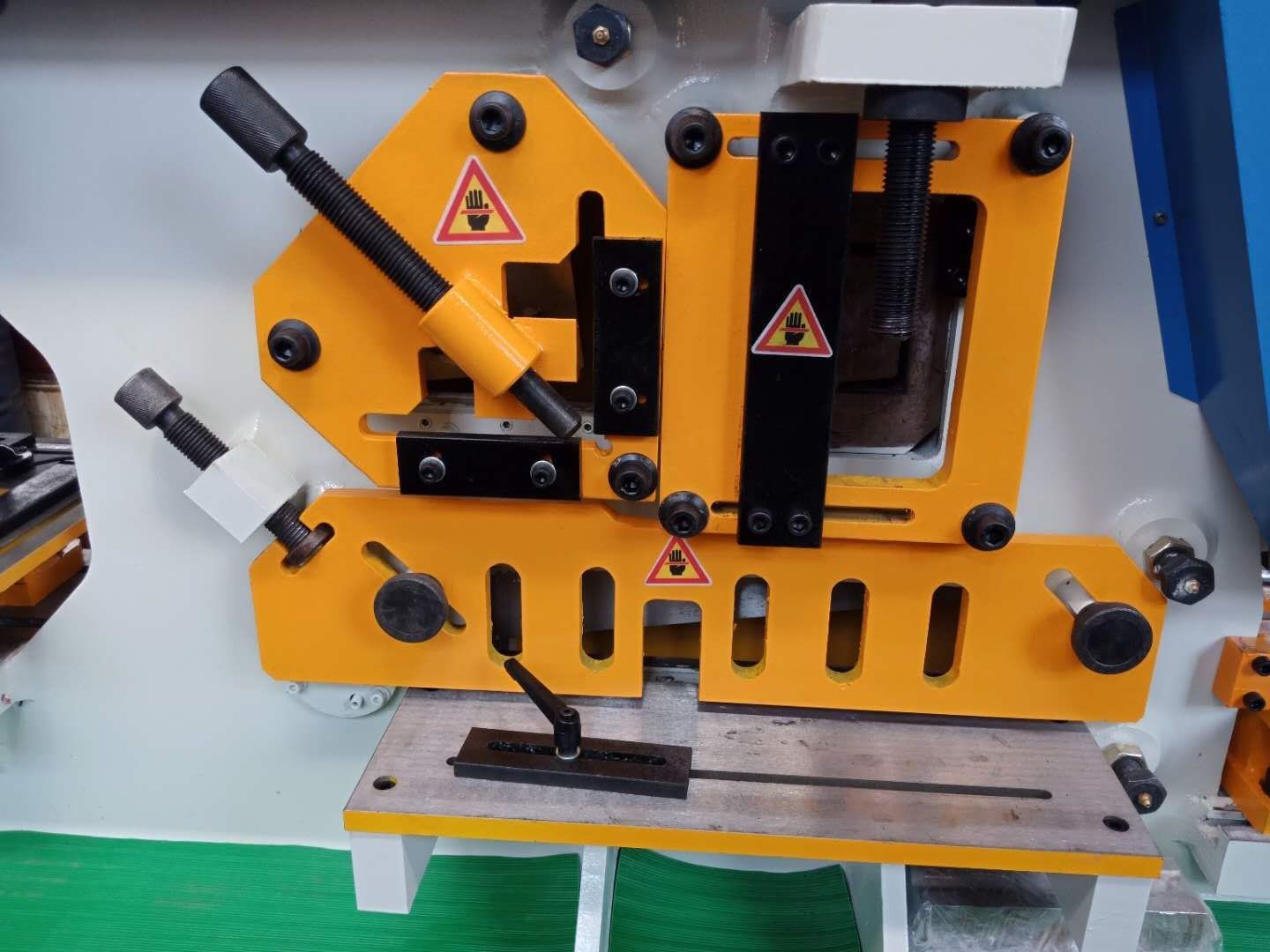

Shape shearing parts

Round and square bar shear has multiple holes for a variety of sizes. Adjustment hold down device for round/square bar,channel/beam cutting. Large strong guarding or max safety.

The angle shear has the ability to cut angle at 45 degree both top and bottom leg. This give the operator to make a picture frame corner for perfect welds.Diamond shaped blade for quality cuts that is minimal material lost and deformity.

Notching parts

Unique design allows for cutting of angle and flat bar. Electrical interlock safety guard and 3 gauging stops for precise positioning.

Notching is a metal-cutting process used on sheet metal or thin bar stock, sometimes on angle sections or tube.

Punching parts

Full range of universal punches and dies are available. Unique style allows for large angle iron punching and large channel punching.

Large viewing window on stripper swing away design for ease of operation. Large 2 piece gauging table with rulers and stop as standard fittings. Quick change coupling nut and sleeve for rapid replacement of change.

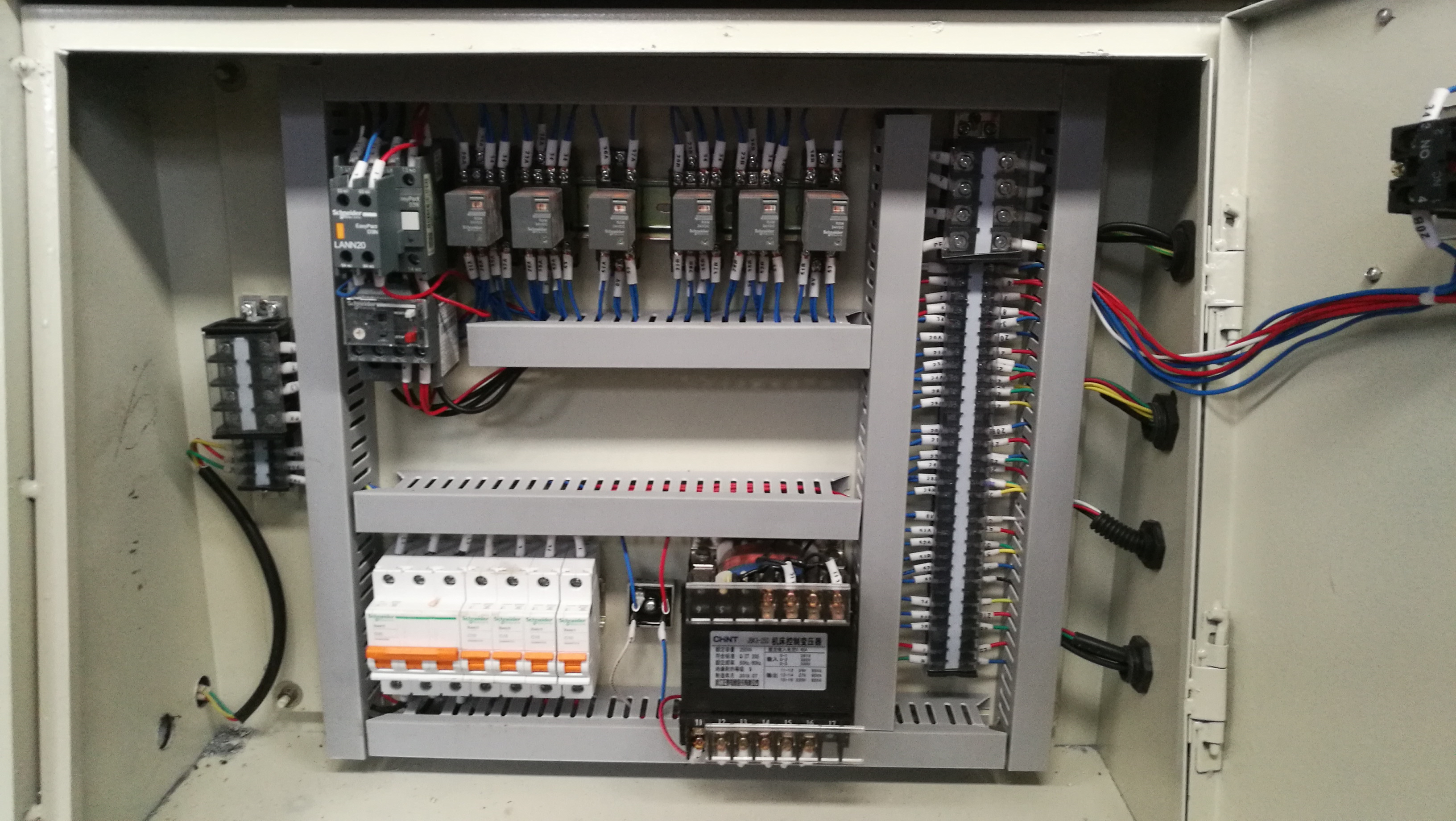

Ironworker control parts

Very easy to operate, hand operating,

safe and easy.

safe and easy.

Puching hole tooling

Punching head

Bending tooling

Lead time

15 days to 40 days

Payment Method

30% T/T in advance, the balance paid before shipping

irrevocable L/C at sight

irrevocable L/C at sight

FAQ&Contact us

Q:How to choose a hydraulic ironworker machine?

A:Please tell us the following information in detail:

- Material of plate:

-Max thickness:

-Max plate width:

-If possible: you can specify the model;

Q:Where is your factory? How can I get there?

A:You can fly to NanJing LuKou airport directly, we will pick you up in the airport. All our customers, both inland and abroad, warmly welcome to visit us!

Q:How do you ensure quality in the factory?

A:Quality culture.:We always attach great importance to quality control from the beginning to the end. Our factory has obtained ISO, CE certification.

Q:How can I pay?

A:You can pay by T/T, Western Union, MoneyGram, Paypal; 30% deposit; pay off the 70% balance before shipment.

Q: How long to produce?

A: Delivery time:15-35 days.

Hot Searches