- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Current:

-

50-60HZ

-

Dimensions:

-

4100*2200*2400mm

-

Use:

-

suitable for cold plate/aluminum plate/metal

-

Product name:

-

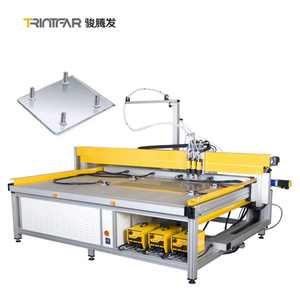

Automatic CNC Stud Welding Machine Platform With 1-8 Torch Weld Head

-

Application:

-

cold plate/galvanized plate/aluminum plate

-

Function:

-

Automatic Stud Welding Machine

-

Welding speed:

-

30-40 pieces/min

-

welding method:

-

Capacitor discharge

-

Stud feeding method:

-

automatic stud feeding

-

Power:

-

3 KW

-

welding range:

-

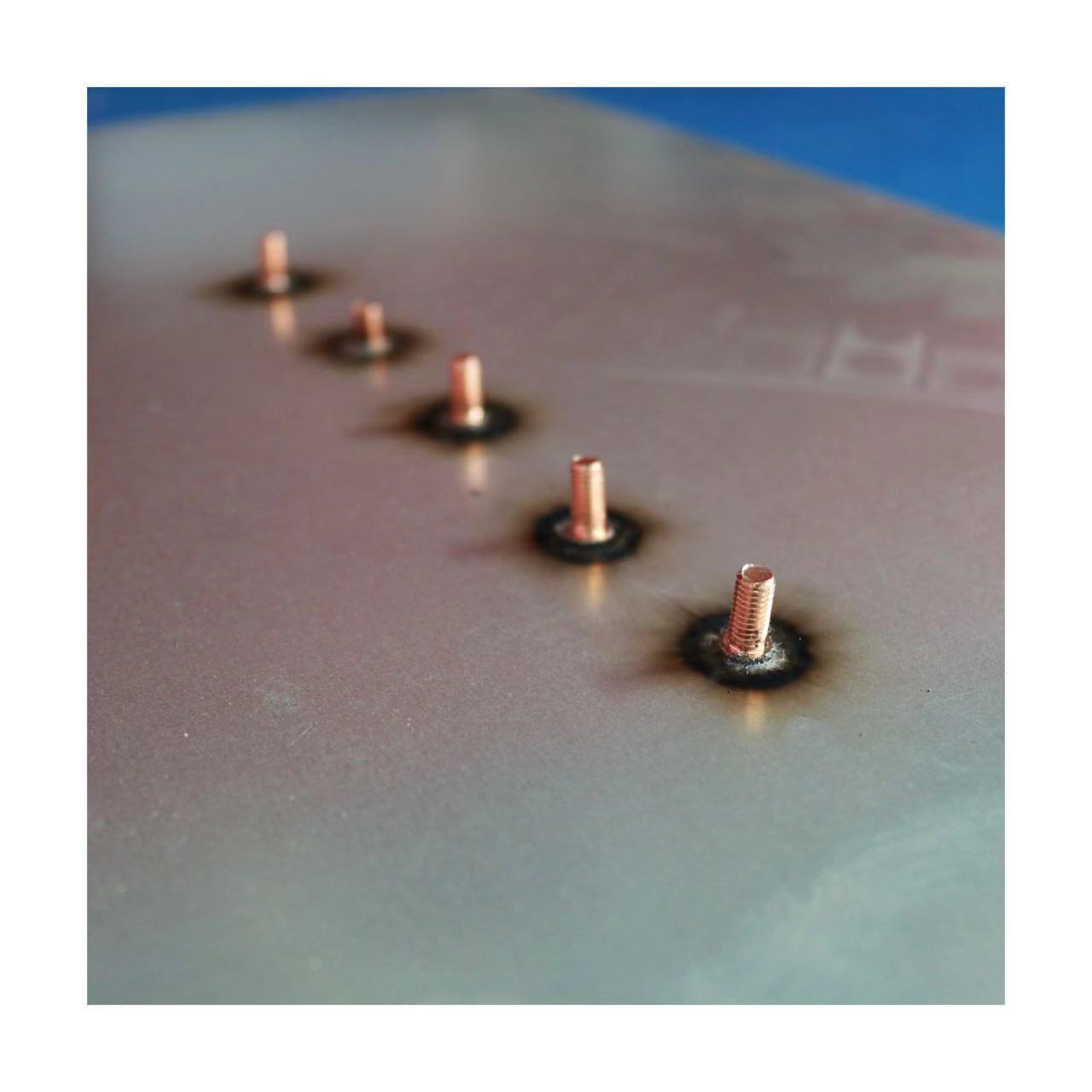

stud diameter M3-M10

-

Number of stud welding head:

-

1-8 pcs

-

Color:

-

Customized

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Ruichuang

-

Weight (KG):

-

980

-

Voltage:

-

380V

-

Current:

-

50-60HZ

-

Dimensions:

-

4100*2200*2400mm

-

Use:

-

suitable for cold plate/aluminum plate/metal

-

Product name:

-

Automatic CNC Stud Welding Machine Platform With 1-8 Torch Weld Head

-

Application:

-

cold plate/galvanized plate/aluminum plate

-

Function:

-

Automatic Stud Welding Machine

-

Welding speed:

-

30-40 pieces/min

-

welding method:

-

Capacitor discharge

-

Stud feeding method:

-

automatic stud feeding

-

Power:

-

3 KW

-

welding range:

-

stud diameter M3-M10

-

Number of stud welding head:

-

1-8 pcs

-

Color:

-

Customized

PRODUCT DESCRIPTION

|

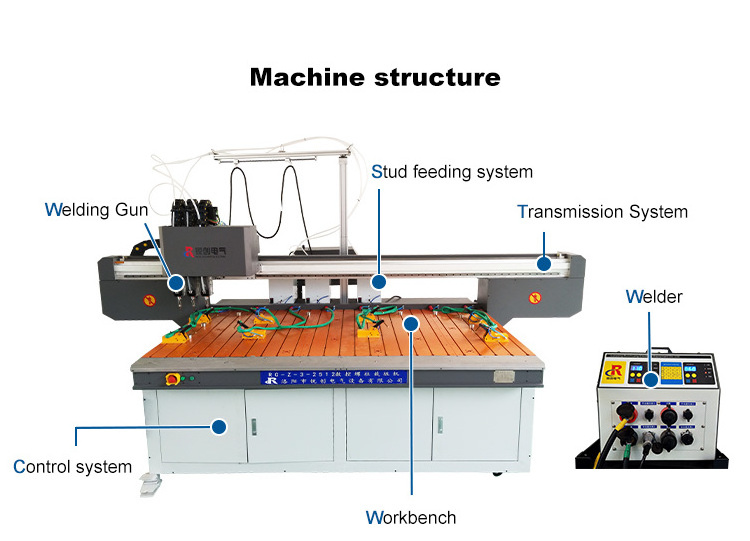

Model No.

|

RC-Z-2212

|

Drive Method

|

Servo motor / pneumatic

|

|

Max. Working Stroke

|

2200mm×1200mm×300 mm

|

Z-axis travel

|

Pneumatic, 150 mm

|

|

Overall Dimension (L*W*H)

|

4100×2200× 2400 mm

|

|

Servo, 150mm

|

|

X Y Fastest moving

speed |

55 m/min

|

Z fastest moving speed

|

15 m/min

|

|

Stud diameter (mm)

|

M3-M10, can be customized

|

Energy storage Welder

|

1 pc

|

|

Stud length (mm)

|

8-35 mm, can be customized

|

Timing belt accuracy

|

C7

|

|

Automatic welding head

|

1-6 pcs, can be customized

|

Number of mobile

clamps |

8 pcs

|

|

Welding accuracy

|

±0.15 mm

|

Welding speed

|

25~35pcs/min

|

|

Gas source - Gas

consumption |

0.3 m³/min

|

Automatic stud feeder/set

|

3, can be customized

|

|

Gas source - Pressure

|

0.6 Mpa

|

Axis qty

|

3

|

|

Working Power

|

380V/50HZ

|

Frame structure

|

Gantry

|

|

Motor Power/KW

|

3 KW

|

Platform Pad

|

Bakelite

|

DETAILED DESCRIPTION

Three types of welding head for option

Direct feed torch

Simple structure, fast nailing speed. Suitable for welding stainless steel and cold-rolled steel plate materials.

Oblique feed welding

torch

Comprehensive functions, stable welding, long service life of gun head, suitable for any material.

Fully automatic oblique feed welding torch

It can automatically adjust to welding nails of different lengths.

The horizontal structure is convenient for loading and unloading, the aluminum beam has high precision and light weight. Heavy frame, CNC high precision machining.

High-precision belt drive, double servo drive, high precision and fast speed the maximum running speed can reach 60 m/s.

Various programming methods support teaching / laser point / CAD and so on. The handheld box with touchscreen is convenient and flexible.

Clamping device

The welding platform is composed of insulated bakelite, air cylinder, floating ball and pneumatic clamp. The tightening device is a mobile clamp. The tightening height, angle, and position can be adjusted arbitrarily according to the size of the workpiece, and it can clamp the workpiece with folded edges.

Double-capacity welding machine with communication, the life is twice as long as others, one group can be switched to another group if there is a failure. One welder can be equipped with 6 welding guns.

Ruichuang machine have A&B two work stations. When the A station workpiece is welded, the system will automatically weld the B station workpiece which can realize the alternate use of A and B stations, which greatly improves production efficiency.

OUR SUPPLY ADVANTAGES

Technical solution can be made in

3 working days

for customized product,

and finished product can be produced in

20 working days

.

ABOUT US

Established in 1993, Luoyang Ruichuang Electrical Equipment Co., Ltd. is located in the High-tech Development Zone of China (Henan) Free Trade Zone. It is a high-tech enterprise integrating R&D, design, manufacture, installation and service. The company has advanced management concepts, high-quality talents, first-class research and development capabilities, advanced processing equipment, complete production chain, strict quality inspection system, and professional service team.Innovation is the inexhaustible driving force for our development.

Since its establishment in 1993, our company has been committed to the development of high and low voltage power distribution equipment, sheet metal processing equipment (polyurethane foam sealing and coating equipment, industrial flat inkjet printing equipment, welding automation equipment), customized automation Solutions, robots, etc. The years of experience and technology accumulation in the sheet metal industry enable Ruichuang to provide customers with the most efficient and flexible automation solutions.The product has high degree of automation, reliable performance and simple operation, and has gained trust and support from customers at home and abroad.

CERTIFICATION

The factory has passed ISO 9001 quality management system certification, with perfect technology, quality and inspection control ability, to ensure that the whole process from raw materials into the factory production and processing to finished products factory control.

FAQ

Q1. Are you factory or trading company?

We are professional factory in Sheet metal industry and CNC machinery industry with near 30 years of experience, covering sheet metal fabrication, CNC pu foam sealing machine, CNC stud welding machine, industrial Robot, industrial Flatbed Inkjet Printer, etc.

Q2. What is this CNC pu foam sealing machine used for?

It is used for the sealing of electrical cabinet doors, enclosures, panels, air filters, lighting covers, electronics, auto spare parts and so on, for insulation waterproof and dustproof purpose.

Q3. How long is the lead time?

Normally 20 to 30 working days.

Q4. How long is the warranty of your machines?

Generally 1 year.

Q5. What shipment ways do you support?

By sea, by air, by train, by international express, etc.

Q6. What payment terms do you accept?

We accept T/T, L/C, Alibaba trade assurance order, etc.

Our service:

1. We offer a 24-hour online service.

2. We provide free remote training, operating guide, remote/onsite technical support, etc.

3. We accept OEM and ODM.

Hot Searches