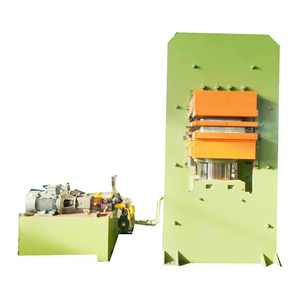

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2800*1300*2300mm

-

Year:

-

Customization

-

Power (kW):

-

4 kW

-

Weight (KG):

-

2600 KG

-

Applicable Industries:

-

Rubber

-

Total Pressure(MN):

-

3.15

-

Dayloigh(mm):

-

300

-

Working Layer:

-

2

-

Piston Stroke(mm):

-

300

-

Main Motor Power(KW):

-

4

-

Control Type:

-

CNC

-

After-sales Service Provided:

-

Video Technical Support, Video technical support

-

Heating Mode:

-

Electric Heating

-

Mode Of Production:

-

Support Customization

-

Certification:

-

ISO9001:2008/CE/SGS

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SFC

-

Voltage:

-

Required

-

Dimension(L*W*H):

-

2800*1300*2300mm

-

Year:

-

Customization

-

Power (kW):

-

4 kW

-

Weight (KG):

-

2600 KG

-

Applicable Industries:

-

Rubber

-

Total Pressure(MN):

-

3.15

-

Dayloigh(mm):

-

300

-

Working Layer:

-

2

-

Piston Stroke(mm):

-

300

-

Main Motor Power(KW):

-

4

-

Control Type:

-

CNC

-

After-sales Service Provided:

-

Video Technical Support, Video technical support

-

Heating Mode:

-

Electric Heating

-

Mode Of Production:

-

Support Customization

-

Certification:

-

ISO9001:2008/CE/SGS

Product Description

Specification

|

item

|

value

|

|

Place of Origin

|

China

|

|

|

Shandong

|

|

Brand Name

|

SFC

|

|

Type

|

Vulcanizer

|

|

Condition

|

New

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

Hot Product 2019

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

PLC, Motor, Gear

|

|

Tire Machine Type

|

Other Tire Machine

|

|

Voltage

|

Required

|

|

Dimension(L*W*H)

|

2800*1300*2300mm

|

|

Certification

|

ISO9001:2008/CE/SGS

|

|

Year

|

Customization

|

|

Warranty

|

1 Year

|

|

|

Video technical support

|

|

Key Selling Points

|

Competitive Price

|

|

Power (kW)

|

4kW

|

|

Weight (KG)

|

2600KG

|

|

After Warranty Service

|

Video technical support, Spare parts

|

|

Applicable Industries

|

Rubber

|

|

Local Service Location

|

None

|

|

Showroom Location

|

None

|

|

Total Pressure(MN)

|

3.15

|

|

Dayloigh(mm)

|

300

|

|

Working Layer

|

2

|

|

Piston Stroke(mm)

|

300

|

|

Main Motor Power(KW)

|

4

|

|

Control Type

|

CNC

|

|

Warranty

|

1 year

|

|

After-sales Service Provided

|

Video Technical Support

|

|

Heating Mode

|

Electric Heating

|

|

Mode Of Production

|

Support Customization

|

Details Of Vulcanizing Press

1. Simple and convenient structure, flexible operation, commodious space. The cylinder and plunger are made up of high quality materials.

1. Simple and convenient structure, flexible operation, commodious space. The cylinder and plunger are made up of high quality materials.

2. Being a column structure and downward pressing type, the heating plate opens by the self-weight of the heating plate, platform and plunger. The rising of the plunger makes the heating plate close while the hydraulic oil provides the pressure.

3. Electrical control system:Complete the perfect control system (including wire and cable and safety protection devices, etc.),Use automatic time relay,can achieve Automatic close mold,exhaust,stuffy,Vulcanization time, supplement pressure,open mold etc working process, also the automatic control and hand control can be switched easily.

4. Up and down platforms:Adopts Q235 steel plates. In order to guarantee the make precision, it is applied with automatic cutting baiting, mechanical slicer producing welded groove, carbon dioxide gas shielded welding.

5. Hydro-cylinder:Adopts ZG270-500 and piston stroke adpots hard cold chilled alloy cast iron, And sealing structure applies the combined structure with double sealing ring and one dustproof ring to guarantee longer service.

6. Customers can choose according to their needs.

7. New design concept, strong technical force and advanced manufacturing processes of the press ensures that each vulcanizing press can be manufactured to meet customer's individual requests.

PLC-VE

Brand: SFC

Original: China

PLC-VE is convenient to control

Hydraulic Pressure Station

Original: China

Hydraulic unit provide the the pressure to push the plunger piston moving

Hot Plate

Original: China

Hot plate act as working platform and provide the needing temperature for vulcanizing.

Our Services

♦ In the process of production, we will take photos and send to customers for their track the progress.

♦ Documents such as packing list, commercial invoice, and bill of lading etc. will be sent after the delivery.

♦ We could supply free English foundation DWG, installation drawing, user guide, maintenance manual and part drawing.

♦ We supply overseas engineer service and help to train your workers to operate the machine.

Packing & Delivery

The equipment shall be delivered after coating, and then wrapped with tensile film to avoid rubbing the paint on the surface. Wooden packaging can be customized. Key components, such as electronic control box, shall be packed with packaging materials to prevent vibration, and then packed in wooden box.

Hot Searches