This combine filling and seaming machine unit suitable for producing drink ( Not carbonated) or high capacity production line for canned food for soup/brine filling and seaming

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

0.5g - 0.8g

-

Voltage:

-

220 / 380V or other

-

Place of Origin:

-

China

-

Brand Name:

-

WILLMAN

-

Dimension(L*W*H):

-

3500 x 1950x 2200mm

-

Weight:

-

5.5 T

-

Usage:

-

Canned Food

-

Material:

-

SUS304 Stainless Steel

-

Feature:

-

Easy Operated / Energy saving

-

Package:

-

Wooden Box

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Colombia, None

-

After-sales Service Provided:

-

Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

-

Marketing Type:

-

Hot Product 2019

-

Certification:

-

CE

Quick Details

-

Machinery Capacity:

-

2000BPH

-

Packaging Material:

-

Metal

-

Filling Material:

-

Beer, Milk, Juice, Other

-

Filling Accuracy:

-

0.5g - 0.8g

-

Voltage:

-

220 / 380V or other

-

Place of Origin:

-

China

-

Brand Name:

-

WILLMAN

-

Dimension(L*W*H):

-

3500 x 1950x 2200mm

-

Weight:

-

5.5 T

-

Usage:

-

Canned Food

-

Material:

-

SUS304 Stainless Steel

-

Feature:

-

Easy Operated / Energy saving

-

Package:

-

Wooden Box

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Colombia, None

-

After-sales Service Provided:

-

Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

-

Marketing Type:

-

Hot Product 2019

-

Certification:

-

CE

Professional Canned food and beverage Manufacturer

Packaging Machinery Solution Provider

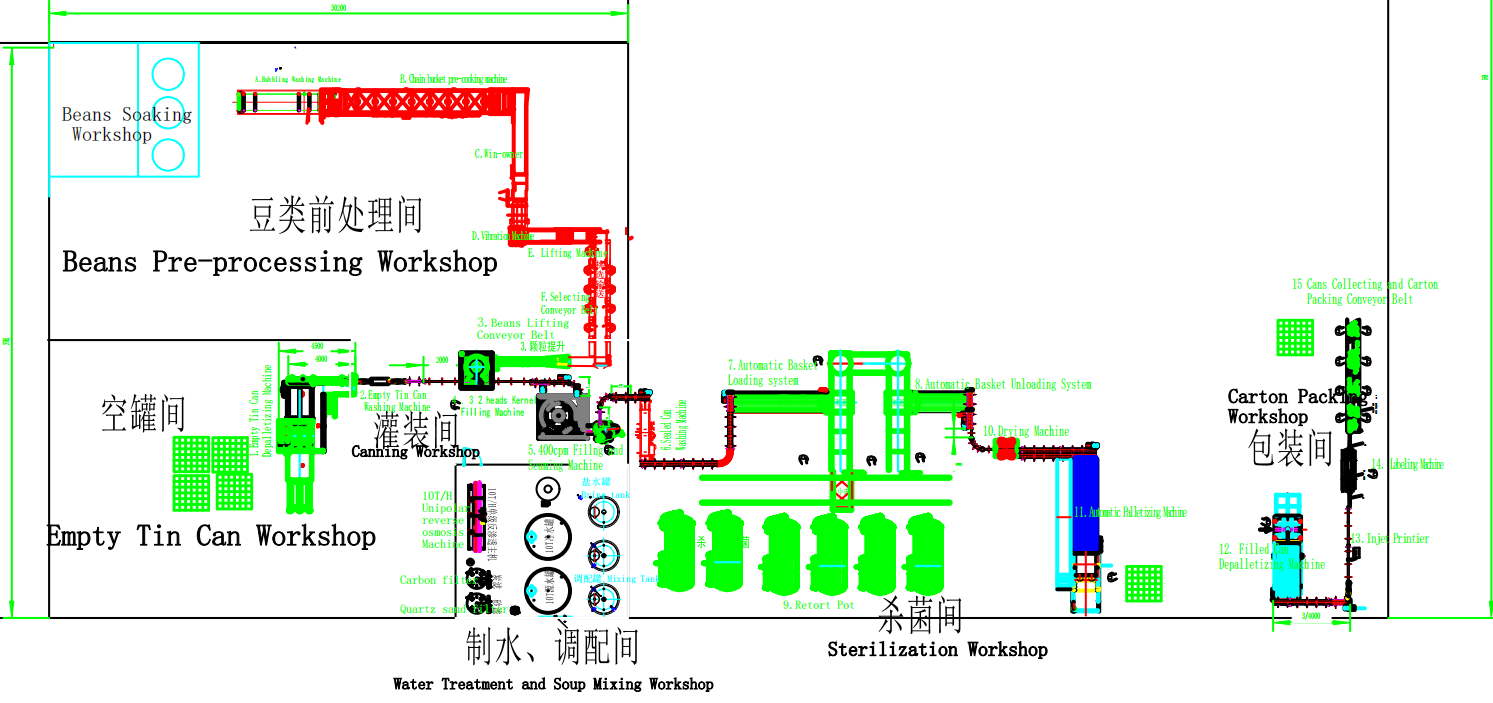

Canned Sweet Corn Production Line (5-10 tons /hour available)

Canned Mackerel/Sardine/ tuna production line ( Capacity 60-80 tons/day available)

Canned Sardine production line (

Capacity 60-80 tons/day available

)

Canned Tomato Paste Production line ( capacity 3-100T/h available)

Canned beans Production line (Capacity 100 -400 cpm available)

PROVIDE WHOLE PRODUCTION LINE SOLUTION FOR CANNED FOOD

Product Overview

According to the actual situation of domestic large and medium-sized canning factories and beverage factories, our company designs and manufactures a new generation of filling and sealing combined machine with reference to the most advanced can sealing and filling similar products in Switzerland. It adopts pneumatic control automatic lower cover

without tank body contact, adopts equal liquid level filling technology, and the production capacity is frequency conversion speed regulation, which ensures the beauty and hygiene requirements of the whole machine. In order to improve the vacuum degree in the tank, steam injection device can be configured according to customer requirements, and remote monitoring system can be equipped to ensure the improvement of technical support for customers.

without tank body contact, adopts equal liquid level filling technology, and the production capacity is frequency conversion speed regulation, which ensures the beauty and hygiene requirements of the whole machine. In order to improve the vacuum degree in the tank, steam injection device can be configured according to customer requirements, and remote monitoring system can be equipped to ensure the improvement of technical support for customers.

This filling-capping 2 -in-1 unit Beverage Machinery is used to produce canned beverage in tin can or aluminum cans for alcoholic beverage machinery and other non-gas beverage machinery.

This is beverage machinery combine the process can filling and sealing, it can reduce the materials and Outsiders touch time, improve the sanitary conditions, production capacity and economic efficiency.

FEATURES AT A GLANCE

Filling Part

Seaming Part

Liquid Nitrogen Dosing Machine (For drinks)

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Data

|

|

1

|

Seamer Heads

|

6

|

|

2

|

Filling Heads

|

24

|

|

3

|

Capacity

|

100-300 CPM

|

|

4

|

Applicable Can Height

|

39-178mm

|

|

5

|

Application can diameter

|

52.5 ~ 99mm

|

|

6

|

Power

|

11 Kw

|

|

7

|

Dimension

|

3500 x 1950x 2200mm

|

|

8

|

Weight

|

5.5T

|

PRODUCT CONFIGURATION

Seaming Rollers and Chucks

Filling Valve

Filling disc

SALES AND SERVICE NETWORK

Successful Project

330ML SLEEK ALUMINUM CAN BEVERAGE PRODUCTION IS WORKING IN CUSTOMER'S FACTORY

330ML STANDARD ALUMINUM CAN BEVERAGE PRODUCTION IS WORKING IN CUSTOMER'S FACTORY

250ML TIN CAN BEVERAGE PRODUCTION IS WORKING IN CUSTOMER'S FACTORY

SIMILAR PRODUCTS

FAQ

Q1: Do you have reference project?

A1: We have reference project in most countries,If we get the permission of the customer who has brought the machines from us ,we can tell you their contact imformation,you can go to vist their factory.

And you are always welcome to come to visit our company,and see the machine running in our factory,we can pick you up from the airport in our city.

Contact our sales people you can get video of our reference running machine

Q2: Do you provide customized service

A2: We can design the machines according your requirements(material ,power,filling type,the kinds of the bottles,and so on),at the same time we will give you our professional suggestion,as you know,we have been in this industry for many years.

Q3: What's your guarantee or the warranty of the quality if we buy your machines?

A3: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q4: How long time for installation?

A4: According your machines order,we will send one or two engineers to your plant,it will take about 7 days to 25 days.

A1: We have reference project in most countries,If we get the permission of the customer who has brought the machines from us ,we can tell you their contact imformation,you can go to vist their factory.

And you are always welcome to come to visit our company,and see the machine running in our factory,we can pick you up from the airport in our city.

Contact our sales people you can get video of our reference running machine

Q2: Do you provide customized service

A2: We can design the machines according your requirements(material ,power,filling type,the kinds of the bottles,and so on),at the same time we will give you our professional suggestion,as you know,we have been in this industry for many years.

Q3: What's your guarantee or the warranty of the quality if we buy your machines?

A3: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q4: How long time for installation?

A4: According your machines order,we will send one or two engineers to your plant,it will take about 7 days to 25 days.

Hot Searches