- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

FIM

-

Voltage:

-

380V or customize

-

Dimension(L*W*H):

-

0.8*1.0*1.0m

-

Power (kW):

-

7.5

-

Weight (T):

-

0.4

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

Any color

-

Name:

-

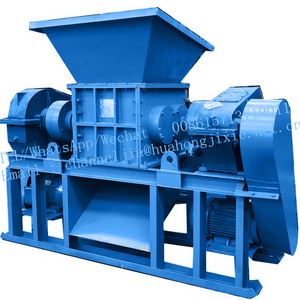

Double shaft shredder

-

Raw material:

-

waste plastic shed

-

Spare parts supply:

-

Anytime

-

After sale Service:

-

Maintenance

-

Test&Installation:

-

Professional Engineer Assigned

-

Capacity:

-

80-3000kgs/h

-

Place of origin:

-

Henan Province

-

Keyword:

-

Plastic Shreeder

Quick Details

-

Max.Production Capacity (kg/h):

-

30000

-

Place of Origin:

-

Henan, China

-

Production Capacity (kg/h):

-

80 - 30000 kg/h

-

Brand Name:

-

FIM

-

Voltage:

-

380V or customize

-

Dimension(L*W*H):

-

0.8*1.0*1.0m

-

Power (kW):

-

7.5

-

Weight (T):

-

0.4

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

Any color

-

Name:

-

Double shaft shredder

-

Raw material:

-

waste plastic shed

-

Spare parts supply:

-

Anytime

-

After sale Service:

-

Maintenance

-

Test&Installation:

-

Professional Engineer Assigned

-

Capacity:

-

80-3000kgs/h

-

Place of origin:

-

Henan Province

-

Keyword:

-

Plastic Shreeder

3000kg/h waste wood metal tire recycling cutting shredding crushing production line waste textile straw shredder for clothes

1.The plastic shredder is mainly used in all kinds of hollow or solid plastic material. The shredder machine is suitable to PE, PP, PVC, PA, EVA, PET, ABS and engineering plastics.

2.This single shaft plastic shredder is new designed especially for shredding various big solid materials, unmanageable materials, plastic container and barrel, plastic film, plastic pipe, fiber and paper which the normal crusher can not handle.

3.The materials are pushed into the shredding chamber by hydraulic. Independent drive system and solid structure make the running stably.

3.The materials are pushed into the shredding chamber by hydraulic. Independent drive system and solid structure make the running stably.

Product Paramenters

|

Model

|

Cutter Diameter(mm)

|

Crushing Chamber Size(mm)

|

Output(t/h)

|

Dimensions(m)

|

Weight(kg)

|

|

FM400

|

150-260

|

400×430

|

0.2-0.5

|

2.1×1×1.5

|

1200

|

|

FM600

|

200-400

|

600×430

|

0.8-1.5

|

2.6×1.2×1.5

|

1800

|

|

FM800

|

220-500

|

800×630

|

1.5-3

|

3.4×1.7×1.8

|

3500

|

|

FM1000

|

300-600

|

1000×760

|

2.5-4

|

4×1.9×1.9

|

5500

|

|

FM1200

|

350-600

|

1200×760

|

4-5

|

4.2×1.9×2.1

|

8500

|

|

FM1400

|

400-600

|

1400×900

|

5-6.5

|

4.5×2.1×2.5

|

11500

|

|

FM1600

|

400-700

|

1600×1100

|

8-50

|

5.3×2.3×3.2

|

15000

|

|

FM1800

|

500-750

|

1800×1200

|

10-60

|

5.8×2.3×3.2

|

22000

|

|

FM2000

|

600-900

|

2000×1500

|

15-80

|

6.3×2.5×3.5

|

35000

|

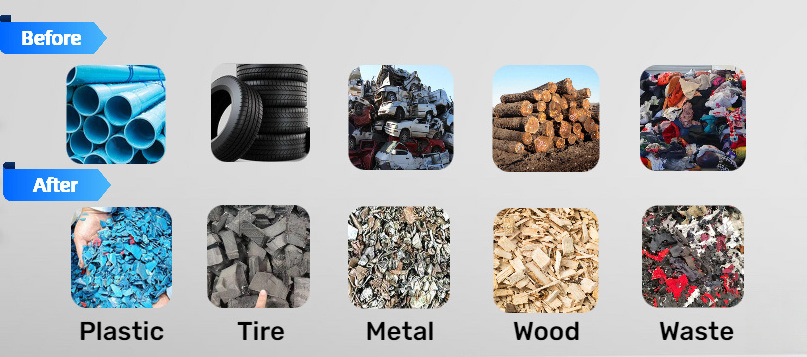

Wide range of applications

Double shaft shredder, also known as shear shredder,which can crush many types of waste material,such as:

-Bucket products: plastic bucket, metal drum, paint bucket, intermediate -bulk container;

-Bucket products: plastic bucket, metal drum, paint bucket, intermediate -bulk container;

-Wastes:

household waste, medical waste, kitchen waste, industrial waste, park waste;

-Plastic products: plastic bottle, plastic frame, plastic block, plastic can -Metal products: aluminum profile, oil filter, car

shell, pop-top can, metal can;

-Paper: newspaper, card paper,corrugated paper, copy paper -Electronic appliances: refrigerator, circuit board, laptop shell, TV set shell, CD disk -Glass.

-Plastic products: plastic bottle, plastic frame, plastic block, plastic can -Metal products: aluminum profile, oil filter, car

shell, pop-top can, metal can;

-Paper: newspaper, card paper,corrugated paper, copy paper -Electronic appliances: refrigerator, circuit board, laptop shell, TV set shell, CD disk -Glass.

Detailed Images

The shredder machine of Speed reducer :

High-quality reducer with high torque, strong power and long service life, we have ZQ series, ZSY series, planetary series, square box series 4 kinds of reducer for you to choose, also can be customized according to your requirements.

The shredder machine of Electric motors :

The motor adopts full copper core motor with low energy consumption and strong power, which improves the service life of the machine.

The shredder machine of Principal axis:

The spindle is made of hexagonal and octagonal shafts depending on the model, and is made of special alloy material for durability, smooth operation and long service life.

The shredder machine of PLC power control system:

PLC power control system automatically detects the running data and automatically controls the forward and reverse function of the machine, which makes the machine run more smoothly.

The shredder machine of Blades :

Blades are made of alloy materials (e.g. 55SiCr, HD13, SKD-11), which are more wear-resistant and provide long service life and low maintenance costs Blade diameter, width and number of teeth can be customized according to the material.

Product Display

Hot Searches