- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Power:

-

96.5kw

-

Dimension(L*W*H):

-

based on model

-

Weight:

-

1300 kg

-

Features:

-

Automatic

-

Warranty:

-

12 months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Capacity:

-

20-25 t/h

-

Mixing system:

-

DWZ2000 Double Shaft Paddle Mixer

-

Raw material:

-

Cement, fly ash, additives, sand, etc

-

Mixer power:

-

18.5kw

-

Discharge capacity:

-

1.56t per batch

-

Feeding capacity:

-

1.56t per batch

-

Mixing cycle time:

-

150S

-

Storage System Model:

-

100T Detachable Silo

-

Pre-mixing Hopper Model:

-

2.0 m3Pre-mixing hopper

Quick Details

-

Application:

-

Dry mortar Production line

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DiHai

-

Voltage:

-

380v

-

Power:

-

96.5kw

-

Dimension(L*W*H):

-

based on model

-

Weight:

-

1300 kg

-

Features:

-

Automatic

-

Warranty:

-

12 months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Capacity:

-

20-25 t/h

-

Mixing system:

-

DWZ2000 Double Shaft Paddle Mixer

-

Raw material:

-

Cement, fly ash, additives, sand, etc

-

Mixer power:

-

18.5kw

-

Discharge capacity:

-

1.56t per batch

-

Feeding capacity:

-

1.56t per batch

-

Mixing cycle time:

-

150S

-

Storage System Model:

-

100T Detachable Silo

-

Pre-mixing Hopper Model:

-

2.0 m3Pre-mixing hopper

Product Description

Application

|

♥ Bonding MortarMasonry mortar,wall(ceramic) and floor tile adhesive mortar etc

|

|

|

|

|

||||

|

♥ Decoration MortarDecorative plaster, inner and outer wall putty, colorful decoration mortar etc

|

|

|

|

|

||||

|

♥ Protection MortarWater-proof mortar, anti-corrosion mortar, self-leveling mortar, wear resistance mortar, thermal insulation

mortar, sound insulation mortar, repair mortar, mildew-proof mortar etc. |

|

|

|

|

||||

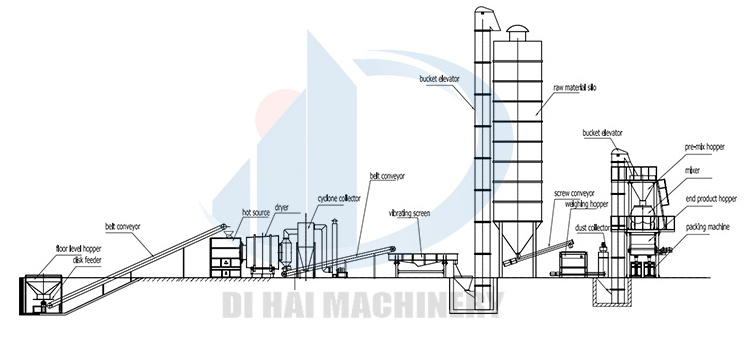

Key Parts

The entire fully automated dry mix mortar production line consists of the following key parts: Drying System,Outdoor Bucket Elevator, Silo, Screw Conveyor, Batching Hopper, Indoor Bucket Elevator, Pre-mix Hopper, Twin Shaft Paddle Non-gravity Mixer, Finished Product Hopper, Packaging Machine, Control Cabinet, Pneumatic System, Mixing Platform.

Details Images

Hot Searches