- Product Details

- {{item.text}}

Quick Details

-

Max. Lifting Load:

-

2000 KG

-

Place of Origin:

-

China

-

Weight (KG):

-

200 kg

-

MOQ:

-

1 Set

-

After-sales Service Provided:

-

Free Replacement Parts

-

Girder Type:

-

Singer Girder/Double Girder

-

Product Name:

-

Single Girder Workstation Overhead Crane

-

Keywords:

-

Lightweight Monorail Cranes

-

Control method:

-

Ground Control+Remote Control

-

Power supply:

-

AC-3Phase-220/230/380/400/415/440V-50/60Hz

-

Application:

-

Lifting Goods

-

After Warranty Service:

-

Accessories Sending

Quick Details

-

Max. Lifting Height:

-

2.5m, 3M, 7.5m, 5M, 4M, Other

-

Marketing Type:

-

New Product 2024

-

Core Components:

-

Tracks, Suspension components, Driving trolley, Electric hoist, Power supply and control system

-

Max. Lifting Load:

-

2000 KG

-

Place of Origin:

-

China

-

Weight (KG):

-

200 kg

-

MOQ:

-

1 Set

-

After-sales Service Provided:

-

Free Replacement Parts

-

Girder Type:

-

Singer Girder/Double Girder

-

Product Name:

-

Single Girder Workstation Overhead Crane

-

Keywords:

-

Lightweight Monorail Cranes

-

Control method:

-

Ground Control+Remote Control

-

Power supply:

-

AC-3Phase-220/230/380/400/415/440V-50/60Hz

-

Application:

-

Lifting Goods

-

After Warranty Service:

-

Accessories Sending

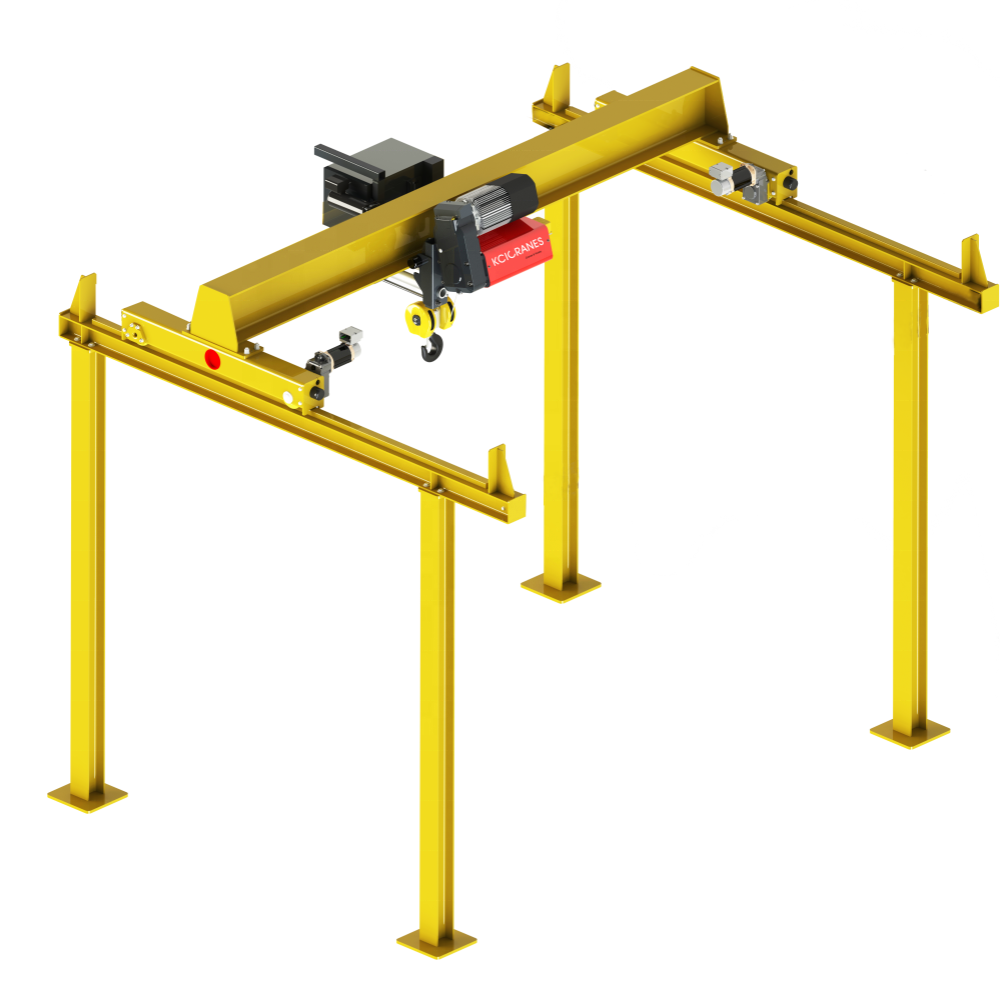

Flexible Workstation Overhead Crane System

The w

orkstation

light crane system offers precise, smooth, and reliable lifting and material handling performance. Whether you require a simple single-track or overhead crane, or an independent workstation crane,

workstation o

verhead crane

's components and systems can provide customized solutions to meet your needs.

●

Lightweight traveling mechanism

●

Simple operation & easy mobility

●

Quick & safe flat lifting operation for various materials

●

Modular Design

●

Space-Efficient

●

Reliable Operation

Product Paramenters

|

FUNCTIONAL CUSTOMIZATION

|

|

|

||

|

1

|

Load Capacity

|

125 kg ~ 2000 kg, Rated lifting capacity up to 3200 kg

|

||

|

2

|

Span Requirements

|

available in single or double beam designs with spans up to 10 meters

|

||

|

3

|

Working Environment

|

working environment temperature between -20°C and +60°C

|

||

|

4

|

Operating Height

|

Load-bearing Capacity

|

||

|

5

|

Control Method

|

Manual drive is simple to operate, electric drive can improve efficiency

|

||

|

6

|

Additional Options

|

automatic walking, anti-collision protection, etc.

|

||

Appilications

Modular workstation overhead crane systems are widely utilized in various industries, including

manufacturing

,

logistics

and

warehousing

,

aerospace

, and

the power sector

.

The application value of modular workstation overhead crane

- Significant improvement in material handling efficiency during production processes

- Reduction of labor-intensive work, leading to more efficient operations

- Decreased waiting time in the production process due to efficient material handling

Advantages of modular workstation overhead crane in material handling

- Provides a more convenient and safe method for material handling

- Reduces labor costs and plays a crucial role in industrial production

- Contributes to production efficiency and development

Hot Searches