- Product Details

- {{item.text}}

Quick Details

-

material:

-

high manganese steel/high chrome/bimetal

-

usage:

-

coal/ore mining

-

application:

-

cement plant, quarry, power plant,mining

-

hardness:

-

35-65HRC

-

heat treatment:

-

annealing, quenching, tempering

-

wanrranty:

-

one year

-

dimension(L*W*H):

-

according to drawings

-

quality tester:

-

ultrasonic fault detector

-

Quality:

-

Excellent

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZHILI

-

certification:

-

ISO9001:2000/BV certificate

-

material:

-

high manganese steel/high chrome/bimetal

-

usage:

-

coal/ore mining

-

application:

-

cement plant, quarry, power plant,mining

-

hardness:

-

35-65HRC

-

heat treatment:

-

annealing, quenching, tempering

-

wanrranty:

-

one year

-

dimension(L*W*H):

-

according to drawings

-

quality tester:

-

ultrasonic fault detector

-

Quality:

-

Excellent

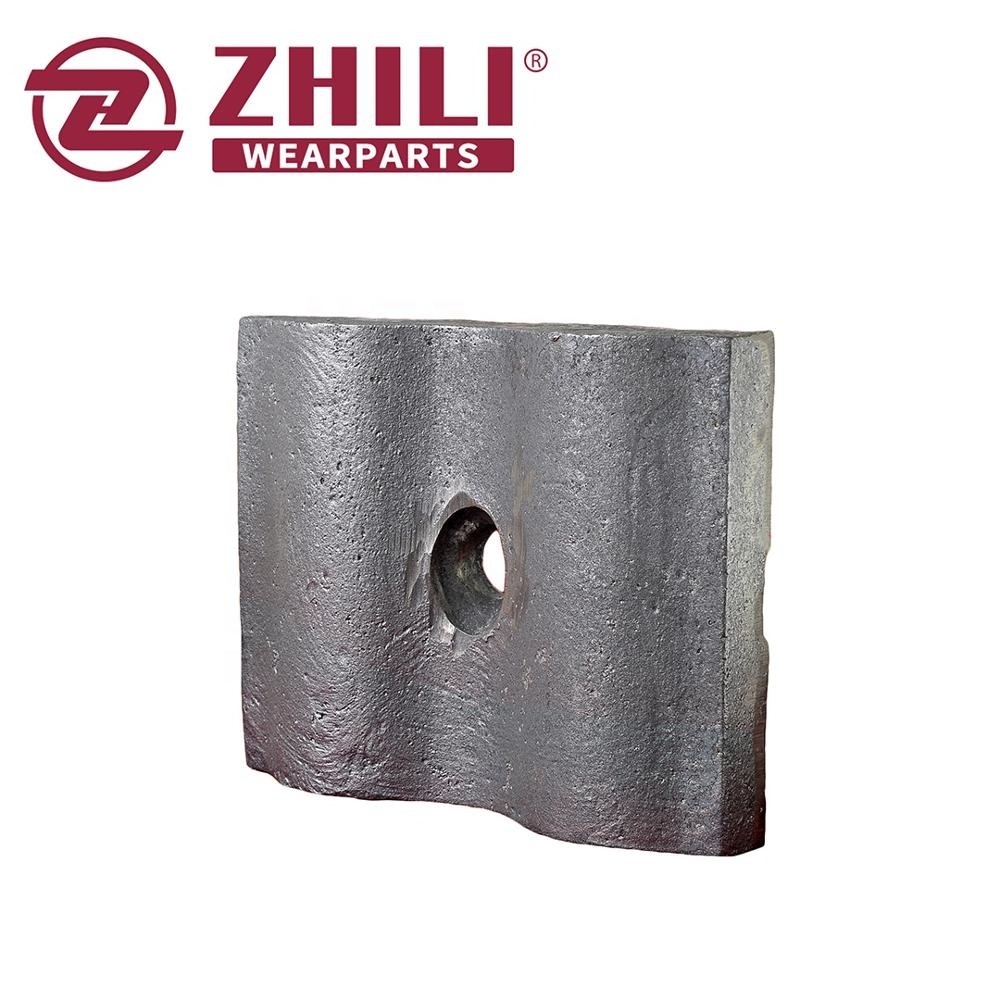

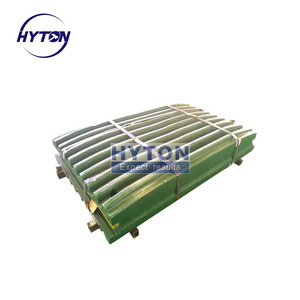

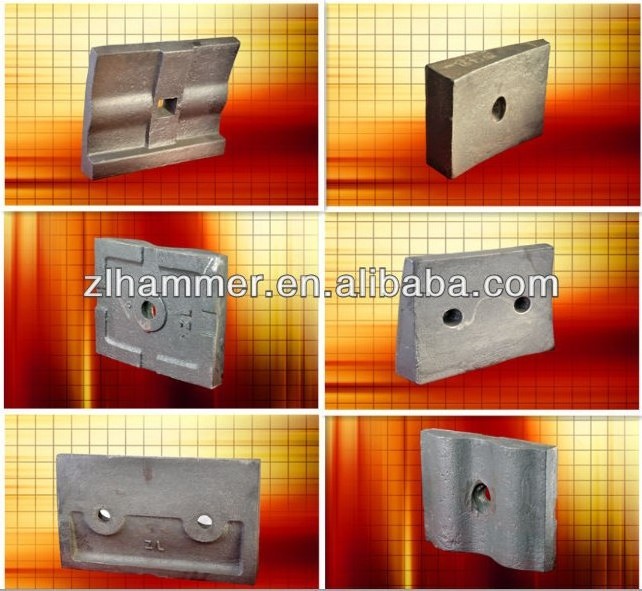

patented products impact crusher high manganese steel mill liner plate

| liner plate | |

| Material | ZGMn13Cr2, ZGMn18Cr2,Cr12,Cr20,Cr26,38CrMoAl,40CrMO,alloy steel,other OEM materials |

| Control | Spectrometer chemical analysis and control while producing |

| Molding Process | Water-glass sand castin/lost form casting |

| Melting facility | Medium frequency electric furnace |

| Heat Treatment | Anneal, quenching, tempering |

| Quality Guarantee | One year against manufacturing defeat |

| Testing | Hardness, flaw detector test |

| Certificate | ISO9001~2008 Passed; BUREAU VERITAS |

|

Chemical Component of casting parts

|

|||||||

|

Material |

C |

Mn |

Cr |

Si |

Mo |

Ni |

Cu |

|

Mn13Cr2 |

1.1~1.4 |

12~15 |

1.7~2.2 |

0.3~1.0 |

|

|

|

|

Mn18Cr2 |

1.1~1.4 |

17~19 |

1.8~2.2 |

0.3~1.0 |

|

|

|

|

Cr12 |

2.0~3.3 |

≤ 2.0 |

11~14 |

≤ 1.2 |

≤ 3.0 |

≤ 2.5 |

≤ 1.2 |

|

Cr15 |

2.0~3.3 |

≤ 2.0 |

11~14 |

≤ 1.2 |

≤ 3.0 |

≤ 2.5 |

≤ 1.2 |

|

Cr20 |

2.0~3.3 |

≤ 2.0 |

14~18 |

≤ 1.2 |

≤ 3.0 |

≤ 2.5 |

≤ 1.2 |

|

Cr26 |

2.0~3.3 |

≤ 2.0 |

23~30 |

≤ 1.2 |

≤ 3.0 |

≤ 2.5 |

≤ 2 |

Suit Filed: cement plants, gravel firms, coal gangue treatment plants and block plants.

Molding:

Molding--Modeling-Casting-Cleaning-Water/oil treatment-Machining.

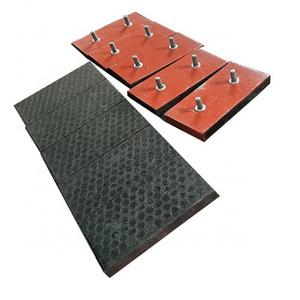

1. Long service life, light weight, thin thicknessand power consumption.

2. Fast replacement and maintenance, easily installed and need less labor work.

3. Widely used for high, medium, and weak magnetic mineral.

4. Attached on the inner wall of cylinder by magnetic force, no pulp leakage and highly efficient.

5. Can be used for nonmagnetic mineral substance, but certain quantity of ferromagnetic substances such as broken steel balls and scrap iron must be added form protection layer.

|

Details |

|

|

Condition |

New |

|

Place of Origin |

Henan,China(Mainland) |

|

Dimension(L*W*H) |

According to drawings |

|

Certificate |

BV certificate,ISO9001:2008 |

|

Application |

Cement plant, Quarry,Power plant, Mining |

|

Warranty |

one year |

|

Supply capacity |

700t per month |

|

MOQ |

1 piece |

|

Brand name |

ZHILI |

|

|

|

|

Delivery |

About 35 days after deposit |

|

Packaging details |

Seaworthy packaging;according to customer's requirement |

|

Port |

Tianjin/Qingdao/Shanghai port |

|

Payment term |

L/C,D/A,D/P,T/T |

|

After-sale Service Provided |

Engineers available to service machinery overseas |

|

|

|

|

Processing technique |

vacuum casting,directional solidification,external refining |

|

Heat treatment |

Annealing, tempering, quenching, |

|

Component test |

Emission spectrometric analysis |

|

Hardness control |

hardness tester |

About our company:

Luoyang ZHILI Industrial Co., Ltd is a professional manufacturer of wear-resistant materials and anti-friction materials.Our company was established in 1995 and has passed ISO9001:2008 International Quality Management Certification and BV certificate.

Our main products:

- Bi-metal thermal composite materials

- Alloyed high manganese hammers

- Super high manganese hammers

- Medium high alloy steel materials

- High-chromium alloy iron materials

- Blow bars

- Hammer block lining plates

- Comb plates

- Grinding balls

- Other customized products

Advantage:

ZHILI hammer was called "the stone killer" by many Chinese users, many products are welcomed home and abroad because of good performance and low price. Our main customers are CEMEX,LAFARGE,POSCO,ARCELOR MITTAL,etc.

Packing :

Our six patents:

Question: What's your company's casting methods?

RE:We support sand casting and lost foam casting.

Question: Can you make products without drawing?

RE: No, we can only make products strictly follow customers' technical drawing.Because every spare parts must be install to the equipment.even little error can make big problem without technical drawing.

Question:What's brand do you manufacture?

RE:We supply casting spare parts for many customers all over the world, OEM is accept.

Question:How long is your products' lifetime?

RE: Even the same products,different working condition has different lifetime. So please let us know your working condition we can give you some technical suggestion.

Question:What's the delivery time?

RE: Usually we the delivery time is 35 days. But we will arrange the Production Scheduling as customers' requirement.

Question:What's the payment term does your company accept?

RE: 30%T/T in advance, the balance pay off before delivery.