- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Ainuok

-

Effective Volume:

-

9m³ ,12m³

-

Dimension(L*W*H):

-

1.8*1.4*1.8

-

Voltage:

-

Custom

-

Weight (KG):

-

1000

-

Power:

-

3.5kw

-

Diameter:

-

1900*2

-

Capacity:

-

800kg per hour

-

three inner containers:

-

3

-

Wood Carbonized Time:

-

For Wood(>15%):8-10 hours

-

Briquette Carbonized Time:

-

For briquettes: 6-8 hours

-

Feeding Capacity(Kg/batch:

-

4.5-6.3T per day

-

Weight:

-

2.6T

-

Dimension:

-

2.1*2.3*1.9m

-

Diameter of inside:

-

1.2m

Quick Details

-

Place of Origin:

-

Henan, China

-

Marketing Type:

-

Hot Carbonization Furnace

-

Core Components:

-

carbonization chamber

-

Brand Name:

-

Ainuok

-

Effective Volume:

-

9m³ ,12m³

-

Dimension(L*W*H):

-

1.8*1.4*1.8

-

Voltage:

-

Custom

-

Weight (KG):

-

1000

-

Power:

-

3.5kw

-

Diameter:

-

1900*2

-

Capacity:

-

800kg per hour

-

three inner containers:

-

3

-

Wood Carbonized Time:

-

For Wood(>15%):8-10 hours

-

Briquette Carbonized Time:

-

For briquettes: 6-8 hours

-

Feeding Capacity(Kg/batch:

-

4.5-6.3T per day

-

Weight:

-

2.6T

-

Dimension:

-

2.1*2.3*1.9m

-

Diameter of inside:

-

1.2m

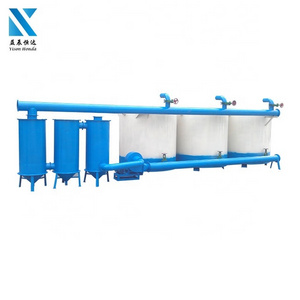

Product Description

Charcoal carbonization furnace is an ideal equipment for making high quality charcoal. It is widely suitable for large range of raw materials.Such as wood log,wood branches,wood chips,sawdust briquette,rice husk /hull, coconut shell, palm kernel shell, olive shell, coffee shell, straws, bagasse etc.After carbonization, the raw material will become final charcoal.

Specification

|

Model

|

Inletstove size

(diameter*length*thickness)

|

Capacity

|

weight

|

|

300

|

1.2*1.5m*6mm

|

300

|

600

|

|

500

|

1.5*1.5m*8mm

|

500

|

1000

|

|

700

|

1.5*2m*10mm

|

700

|

1200

|

|

1000

|

1.3*3m*12mm

|

1000

|

1800

|

Details Images

Good quality

The equipment is made of thick steel, which is durable and wear-resistant, and has a long service life.

Strong sealing

The furnace door is sealed with high temperature rock wool, which has strong sealing performance, carbonization period, high carbon yield and high production efficiency

Add a flue gas recovery device

Add a flue gas recovery device. After the flue gas is recovered, it can be used by itself, burned and heated again, and the excess gas can be recovered and recycled again.

Daily capacity of one set of furnace

2-3T/24hrs for dry wood with moisture less than 8% or wood briquette(usually 2.5-3tons raw materials can get 1 ton final charcoal)

Note : different moisture of the raw materials, the daily productivity will be different & try to make sure the wood log to be similar size, or the carbonize effect will be effected & make sure moisture no more than 50%.

Note : different moisture of the raw materials, the daily productivity will be different & try to make sure the wood log to be similar size, or the carbonize effect will be effected & make sure moisture no more than 50%.

Application

Final product

Application of Final Charcoal

1.Can be used for BBQ, boiler heating, family heating.

2.To make active carbon and other industrial usage.

2.To make active carbon and other industrial usage.

Advantage of carbonization furnace

1.Best carbonization effect and shortest carbonization time.

2.High carbonization rate, no smoking, little pollution, high efficiency.

3.Dry distillation, the carbonization temperature can be controlled and adjusted, the highest temperature can reach 800-1000 °C.

4.Can work continuously 24 hours without stopping.

5.It can collect wood tar oil and exhaust gas which can be recycled.

2.High carbonization rate, no smoking, little pollution, high efficiency.

3.Dry distillation, the carbonization temperature can be controlled and adjusted, the highest temperature can reach 800-1000 °C.

4.Can work continuously 24 hours without stopping.

5.It can collect wood tar oil and exhaust gas which can be recycled.

Carbonization Furnace Factory

Before-sale services

1. Full time on line and in-time reply to your inquiries.

2. Recommend most suitable machines and line according to customer’s requirement.

3.Introduce details of the machine with pictures or video for your good acknowledgement.

2. Recommend most suitable machines and line according to customer’s requirement.

3.Introduce details of the machine with pictures or video for your good acknowledgement.

Sales service

1. Customized machine according to your request.

2. Test and inspect every machine with strict quality control.

3.Packing with standard export wooden box after you confirm the machine

2. Test and inspect every machine with strict quality control.

3.Packing with standard export wooden box after you confirm the machine

After-sales service

1. Offer the professional engineer assist you to use the machine.

2. Offer technical support and professional engineer help you solve problems while using it.

3. Quality warranty for one year. Free repair for quality problem during one year.Spare parts only charge cost price after

warranty.

2. Offer technical support and professional engineer help you solve problems while using it.

3. Quality warranty for one year. Free repair for quality problem during one year.Spare parts only charge cost price after

warranty.

Hot Searches