- Product Details

- {{item.text}}

Quick Details

-

Keywords:

-

Corrugated box making machine

-

Other name:

-

carton making machine prices made in taiwan

-

Item Name:

-

BEST SALE Corrugated box making machine

-

Product name:

-

cardboard carton making machine prices

-

Usage:

-

Corrugated box making machine

-

Machine type:

-

corrugated automatic carton paper making machine

-

Material:

-

corrugated carton production line

-

Function:

-

Corrugated box making machine

Quick Details

-

Application:

-

Food, Beverage, Medical, Chemical, Machinery & Hardware

-

Packaging Material:

-

Plastic

-

Name:

-

3 ply made in taiwan

-

Keywords:

-

Corrugated box making machine

-

Other name:

-

carton making machine prices made in taiwan

-

Item Name:

-

BEST SALE Corrugated box making machine

-

Product name:

-

cardboard carton making machine prices

-

Usage:

-

Corrugated box making machine

-

Machine type:

-

corrugated automatic carton paper making machine

-

Material:

-

corrugated carton production line

-

Function:

-

Corrugated box making machine

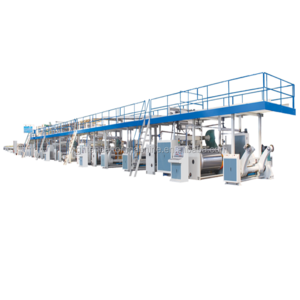

3 ply corrugated carton production line

|

NO |

MACHINES LIST |

QUANTITY |

|

Hydraulic Mill Roll Stand --Support two Dia.1500mm paper mill --Including track and trolley for carry paper mill -- Using multi-point brake |

3 SETS |

|

|

2 |

Preheate r (RG) Ø 9 00mm |

1 SET |

|

3 |

Pre-condition Ø 9 00mm |

1 SET |

|

4 |

Fingerless Single Facer (SF- 3 6 0 c ) --Corrugating roller Dia.3 6 0mm ,with a drum. --Press roller Dia.3 6 5mm. with drum. --Gimbal driver system --Touch screen and PLC control system |

1 SET

|

|

5 |

Single Overhead Bridge --vacuum tension control --Electric paper way control |

1 SET |

|

6 |

Du plex Preheater (RG) Ø9 00mm |

1 SET |

|

7 |

Single Glue Machine -- Glue roller embossed and plated treatment --Independent driver system --Touch screen and PLC control system |

1 SET |

|

8 |

Double Baker Facer (SM- E ) --Including quality cotton belt 1set --including drive roll stand --including 14 pcs( 14 x 600MM) heating plates --New design and in cluding 5 pcs press bar |

1 SET |

|

9 |

Thin blade Slitter Scorer ZQS --4 set slitter k ni ves and 6 set scorer wheel --automatic grinding knives |

1 SET |

|

10 |

N.C Cut-off( helical Knives) --With full Germany servo Computer system --Keeping 999 order |

1 SET |

|

11 |

Paper Sheet Delivery --with automatic calculation computer --the max. Paper delivery length 3500mm |

1 SET |

|

12 |

Internal Steam Pipe System |

1 SET |

|

13 |

Internal Electric System |

1 SET |

|

14 |

Glue Making System |

1 SET |

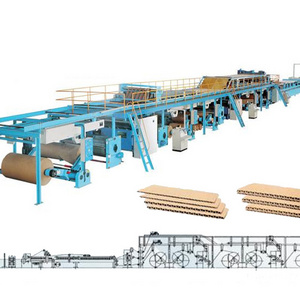

HB-I Hydraulic Mill Roll Stand

1. Machine Description:

*This machine is used for supporting the paper roll, supply the paper to the production line.

2. Machine F unction :

*It can be loading two paper rolls at the same time, without stopping the machine for changing paper roll

*The whole machine use 6 cylinders fully hydraulic controlled, hydraulic control arm lift and down, clamping and open, left and right mov ing

PH- 6 0 Preheater

1. Machine Description:

* This machine is used for heating liner (pre- heating for raw paper), and dry to control temperature and humidity

2. Machine F unction :

* Electric to adjust the wrap angle , preheating area can be in 360° range

*Dishing seal structure on two sides,saving the steam and improving heating efficiency

SF-A15 Single Facer

1. Machine Description:

* Single facer is design for producing single-face corrugated paper

OB H Conveying Bridge

1. Machine F unction :

* Main f rame made by channel steel, and angle steel

* With p rotecting h andrail and safety pedal on both sides, the operation side is installed with safety ladder, to make sure the safety and convenience of the worker

* Vacuum suction tension control, 5 inch suction pipe with adjusting valve,draw fan power can be adjusted freely

GM-1 5 Gluer Machine

1. Machine F unction :

* After the glue roller surface quenched , tempered,gr ound and engraved pit ,then doing balancing ,making coating evenly, consume less glue

* Glue roller controlled by frequency motor , the inverter control ensures glue line speed is synchronous with double facer , and can also operate independently

*Plc control the glue amount, automatically adjusted according to the production speed Automatic circulation for glue, avoiding glue precipitation

DF- 6 0 Double Facer

1 . Machine Descriptio n:

* Corrugated paper enter into the double facer hot parts with heating and molding after pasted glue, and become board after cooling

2. Machine F unction :

* Hot Plates’ surfaces is gr ound and then chromed plated,width 600mm and 1 4 p ics,cooling parts 4m

* Hot plates adopts the press shoes structure ,it lifting adopt pneumatic structure

*Heat conductive pipe of h ot p lates control the temperature s egmented

SS - E Electric Slitter Scorer

1. Machine F unction :

* Frequency motor driving

* 5 blades 8 lines type, blade is made of tungsten alloy steel, cutting smoothly and service life is more than 30,000 m

NC-15 Cut Off Machine

1. Machine F unction :

* The knife adopts spiral steel helical knife structure, serrated knife type, scissors shearing, keeping small shear force and long service life

* The knife ro l l ers adopt high quality precision forged steel material , ha ving good stability after balanced

AS Gantry Stacking

1. Machine F unction :

*Gantry type stacking,change the order in 5 seconds,automatically count, automatically traverse,automatically change orders

*Automatically and smoothly outputs the paper horizontally with inverter control, when the stacking reaches the sett ing quantity

*Rear baffle positioning by AC servo control,changing orders automatically, quickly and pr e cisely