- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220-380V

-

Power:

-

ODM

-

Dimension(L*W*H):

-

ODM

-

Weight (KG):

-

1000

-

Product name:

-

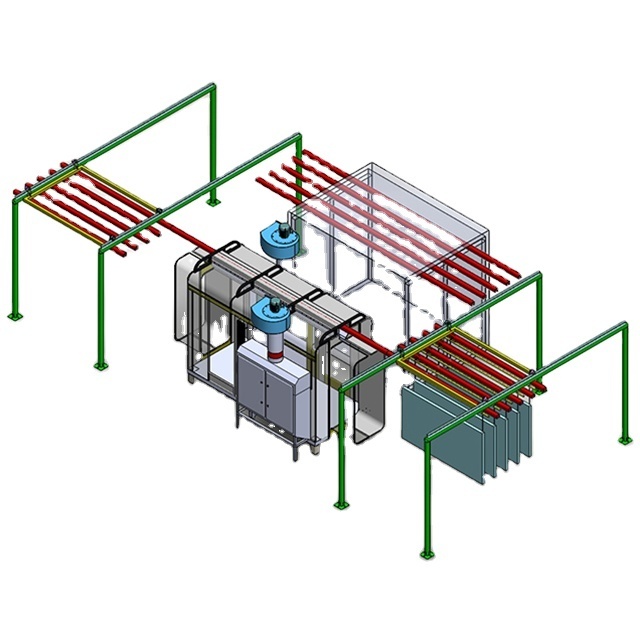

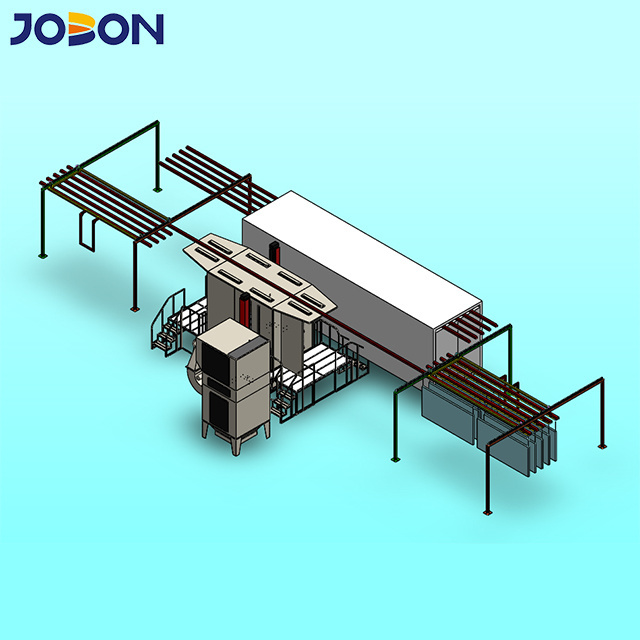

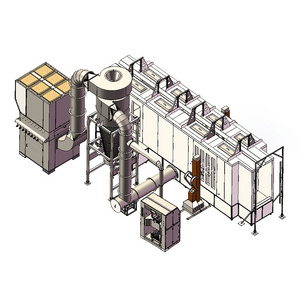

Transverse system powder coating line

-

Production line type:

-

Manual Spraying Production Line

-

Advantage:

-

Automatic positioning and locking system

-

Certification:

-

CE

-

After-sales Service Provided:

-

Online support and full set of installation file

-

Material:

-

All-steel structure support system

-

Control System:

-

Electric Control

-

Conveyor system:

-

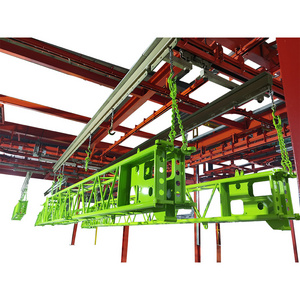

Equipped with loading beam

-

Powder coating oven:

-

Can be electric heating oven, gas oven, or diesel oven

-

Operation:

-

Easy to operate

Quick Details

-

Machine Type:

-

Powder coating system,manual powder coating, Spray Booths, Painting Equipment, Conveying Equipment, Drying Oven, Curing oven, Coating Equipment, Other

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JOBON/PENTOO

-

Voltage:

-

220-380V

-

Power:

-

ODM

-

Dimension(L*W*H):

-

ODM

-

Weight (KG):

-

1000

-

Product name:

-

Transverse system powder coating line

-

Production line type:

-

Manual Spraying Production Line

-

Advantage:

-

Automatic positioning and locking system

-

Certification:

-

CE

-

After-sales Service Provided:

-

Online support and full set of installation file

-

Material:

-

All-steel structure support system

-

Control System:

-

Electric Control

-

Conveyor system:

-

Equipped with loading beam

-

Powder coating oven:

-

Can be electric heating oven, gas oven, or diesel oven

-

Operation:

-

Easy to operate

1. Customized design per client's request

2. Easy to Control

3. Low Maintenance cost

4. High daily production capacity

5. Stable coating thickness

6. Can be equipped with reciprocators to do automatic spraying

7. Can be installed in a limited space

8. All parts' turnover are done with overhead conveyors, no manually moving

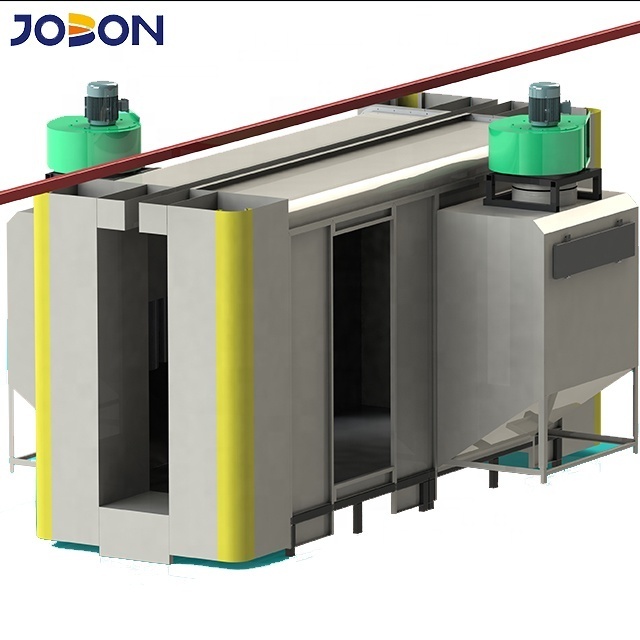

The powder coating booth

The booth with powder recovery system can be settled from standard level to top level,

and it can be designed to exhaust air directly indoors or outdoors through the pipe.

The powder coating oven

The batch oven's heating energy can be electricity, gas, or diesel.

Overhead conveyors are equipped inside of the oven.

The oven dimension affects daily capacity, that means the bigger the oven is, the more products can be heated every day.

The manual powder coating guns

Currently we have two models of powder coating guns: M2 guns & S20 guns.

M2 gun is with 5 patents which can deal with most of the complex parts coatings,

S20 gun is our best guns which owns a world patent, can deal with very deep grooves coatings such as 127*19mm, do penetrating coatings, coating thickness can reach 250um+.

Stable coating thickness

Easy Control

High Production Capacity

Hot Searches