Inquiry:

1.PCB:Pleasep provide gerber file for detail Quote.

2.PCBA:Please provide gerder file and Bom list.

3.COPY PCB/PCBA:Please provide us the details of PCB.Picture and Sample will be better.

Explore More Products

- Product Details

- {{item.text}}

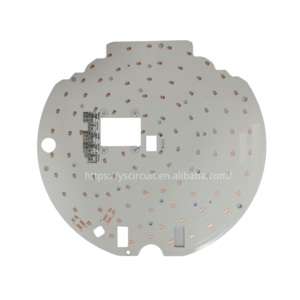

Quick Details

-

Supplier Type:

-

PCB factory

-

product name:

-

LED pcba

-

Base material:

-

FR-4/PTFE/Rogers/aluminum

-

Board Thickness:

-

0.2-6.0mm

-

Min. Line Width:

-

0.075mm(3mil)

-

Min. Line Spacing:

-

0.075mm(3mil)

-

Surface Finishing:

-

HASL/OSP/Ag/ENIG/ENEPIG/Immersion silver,Tin

-

Testing Service:

-

100% E-testing

-

Solder mask color:

-

Blue.green.red.black.white.etc

-

Application:

-

LED

Quick Details

-

Model Number:

-

XZH PCB

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

XZH

-

Supplier Type:

-

PCB factory

-

product name:

-

LED pcba

-

Base material:

-

FR-4/PTFE/Rogers/aluminum

-

Board Thickness:

-

0.2-6.0mm

-

Min. Line Width:

-

0.075mm(3mil)

-

Min. Line Spacing:

-

0.075mm(3mil)

-

Surface Finishing:

-

HASL/OSP/Ag/ENIG/ENEPIG/Immersion silver,Tin

-

Testing Service:

-

100% E-testing

-

Solder mask color:

-

Blue.green.red.black.white.etc

-

Application:

-

LED

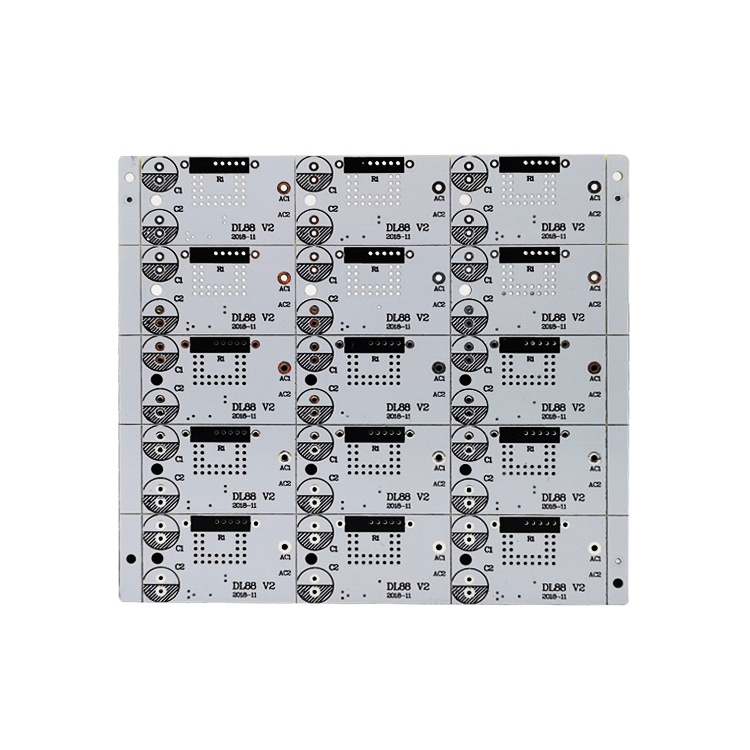

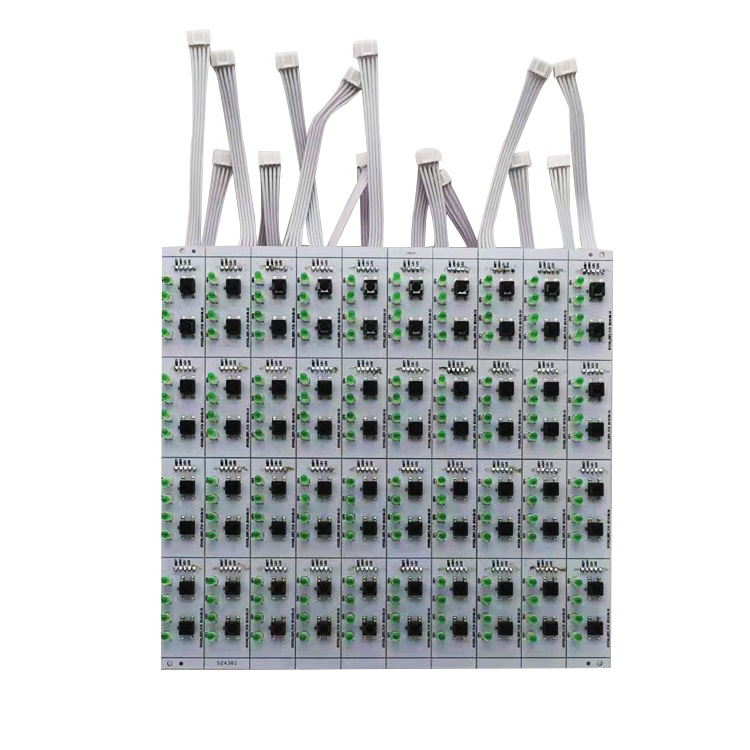

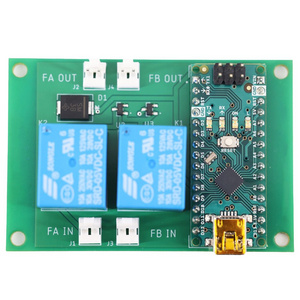

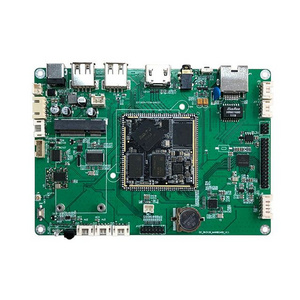

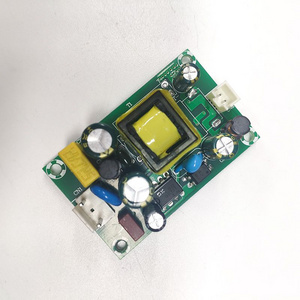

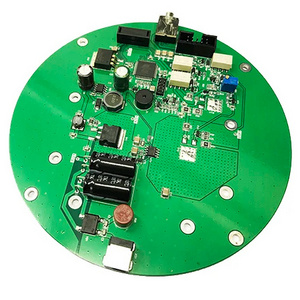

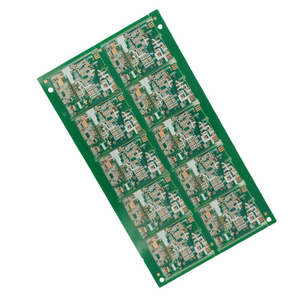

High quality wholesale pcba pcb design led lights module bulb circuit board manufacturers

XZH: Your One-Stop ODM/OEM Solution Provider

Product Description

|

Base Material

|

FR-4 / High TG FR-4 / Halogen Free material/Rogers/Arlon/Taconic/Teflon

|

|

Surface treatment

|

HASL, HASL lead free, Immersion Gold, Immersion Tin, Immersion Silver, Hard gold, Flash gold, OSP…

|

|

Solder mask

|

Double -sided green LPI ,Also support red , white, yellow, blue , black

|

|

Design file format

|

Gerber RS -274X, 274D, Eagle , and AutoCAD's DXF , DWG

|

Detailed terms for PCB assembly:

* Technical requirement:

1. Professional surface-mounting and through-hole soldering technology

2. Various sizes like 1206, 0805, 0603 components SMT technology

3. ICT (in circuit test), FCT (functional circuit test) technology

4. PCB assembly with UL, CE, FCC, RoHS approval

5. Nitrogen gas reflow soldering technology for SMT

6. High standard SMT and solder assembly line

7. High density interconnected board placement technology capacity

Detailed terms for PCB assembly:

* Technical requirement:

1. Professional surface-mounting and through-hole soldering technology

2. Various sizes like 1206, 0805, 0603 components SMT technology

3. ICT (in circuit test), FCT (functional circuit test) technology

4. PCB assembly with UL, CE, FCC, RoHS approval

5. Nitrogen gas reflow soldering technology for SMT

6. High standard SMT and solder assembly line

7. High density interconnected board placement technology capacity

For PCB (Printed Circuit Board) and PCBA (Printed Circuit Board Assembly) logo customization, the logo can be applied to the following areas:

1. PCB Surface: Logos can be printed on the surface of the PCB, typically in an edge area or a designated non-functional zone.

2. PCBA Assembled Components: If there are visible plastic or other non-conductive material parts on the PCBA, logos can also be printed on these components.

3. Packaging Materials: The exterior or interior packaging for PCBs or PCBAs can feature logos, including packaging boxes, plastic bags, or anti-static bags.

The methods for imprinting logos generally include:

1. Screen Printing: Suitable for PCB surfaces and packaging materials, allowing for single or multi-color logo imprints.

2. Inkjet Printing: Enables high-resolution color printing on PCBs or packaging materials.

3. Laser Marking: Ideal for creating permanent logos on non-conductive parts of PCBs or on metal surfaces.

4. Hot Stamping: Adds a tactile finish to packaging materials with logo imprints.

5. Labeling: Applying labels or stickers with logos onto the PCB or PCBA.

1. PCB Surface: Logos can be printed on the surface of the PCB, typically in an edge area or a designated non-functional zone.

2. PCBA Assembled Components: If there are visible plastic or other non-conductive material parts on the PCBA, logos can also be printed on these components.

3. Packaging Materials: The exterior or interior packaging for PCBs or PCBAs can feature logos, including packaging boxes, plastic bags, or anti-static bags.

The methods for imprinting logos generally include:

1. Screen Printing: Suitable for PCB surfaces and packaging materials, allowing for single or multi-color logo imprints.

2. Inkjet Printing: Enables high-resolution color printing on PCBs or packaging materials.

3. Laser Marking: Ideal for creating permanent logos on non-conductive parts of PCBs or on metal surfaces.

4. Hot Stamping: Adds a tactile finish to packaging materials with logo imprints.

5. Labeling: Applying labels or stickers with logos onto the PCB or PCBA.

Custom packaging options may include:

1. Standard Packaging: Using standard anti-static bags or plastic bags with custom labels on the exterior.

2. Custom Packaging Boxes: Designing and manufacturing packaging boxes with logos based on customer requirements.

3. Eco-friendly Packaging: Packaging made from recyclable or biodegradable materials to reflect environmental sustainability.

4. Shockproof Packaging: Custom shockproof packaging for fragile PCBs or PCBAs that require additional protection.

5. Gift Box Packaging: Custom gift box packaging designed for high-end products or special occasions.

In addition to our comprehensive customization services, we also offer collaborative procurement assistance for a wide range of products. Our goal is to streamline your process and save you valuable time.

Click the CHAT NOW button below to contact our salespeople.

1. Standard Packaging: Using standard anti-static bags or plastic bags with custom labels on the exterior.

2. Custom Packaging Boxes: Designing and manufacturing packaging boxes with logos based on customer requirements.

3. Eco-friendly Packaging: Packaging made from recyclable or biodegradable materials to reflect environmental sustainability.

4. Shockproof Packaging: Custom shockproof packaging for fragile PCBs or PCBAs that require additional protection.

5. Gift Box Packaging: Custom gift box packaging designed for high-end products or special occasions.

In addition to our comprehensive customization services, we also offer collaborative procurement assistance for a wide range of products. Our goal is to streamline your process and save you valuable time.

Click the CHAT NOW button below to contact our salespeople.

Recommend Products

Certifications

Hot Searches