- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Highway, Road Construction

-

Design Style:

-

Industrial

-

Weight:

-

20kg/carton

-

Chemical Composition:

-

Manganese, Carbon Steel

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

DAYE

-

Model Number:

-

DY49- Mill-cut Steel Fiber 32mm

-

Product Name:

-

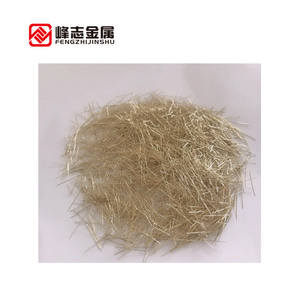

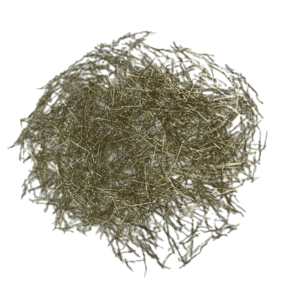

Chopped Milling Steel Fibres for Concrete

-

Size:

-

2.6 x 32 MM

-

Quality Standard:

-

YB/T151-2017, CECS38:2004, JGJ/T221-2010, JT/T524-2004, JTG/T F30-2014

-

Color:

-

Polishing Blue

-

Function:

-

Concrete Reinforcement Anti Crack Quake

-

Tensile Strength:

-

>700 Mpa

-

MOQ:

-

1 Kilogram

-

Packing:

-

Paper Carton

-

Production Time:

-

15-20 Days

-

Payment:

-

30% T/T Prepaid ,70% against Copy of B/L

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Onsite Installation, Onsite Inspection, Free spare parts

-

Project Solution Capability:

-

graphic design, 3D model design, Cross Categories Consolidation

-

Application:

-

Highway, Road Construction

-

Design Style:

-

Industrial

-

Weight:

-

20kg/carton

-

Chemical Composition:

-

Manganese, Carbon Steel

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

DAYE

-

Model Number:

-

DY49- Mill-cut Steel Fiber 32mm

-

Product Name:

-

Chopped Milling Steel Fibres for Concrete

-

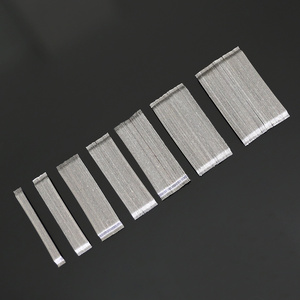

Size:

-

2.6 x 32 MM

-

Quality Standard:

-

YB/T151-2017, CECS38:2004, JGJ/T221-2010, JT/T524-2004, JTG/T F30-2014

-

Color:

-

Polishing Blue

-

Function:

-

Concrete Reinforcement Anti Crack Quake

-

Tensile Strength:

-

>700 Mpa

-

MOQ:

-

1 Kilogram

-

Packing:

-

Paper Carton

-

Production Time:

-

15-20 Days

-

Payment:

-

30% T/T Prepaid ,70% against Copy of B/L

End Hook Chopped Milling Steel Fibers for Concrete Daye Price Hydraulic Engineering Steel Fiber Concrete

Specification

End Hook Chopped Milling Steel Fibers for Concrete Daye Price Hydraulic Engineering Steel Fiber Concrete

Details:

|

Product Name

|

End Hook Chopped Milling Steel Fibers for Concrete Daye Price Hydraulic Engineering Steel Fiber Concrete

|

|

Material

|

Manganese Alloy High-strength Cast Steel

|

|

Width

|

2.6mm±1.2mm

|

|

Length

|

32mm±2mm

|

|

Aspect Ratio

|

35-45

|

|

Tensile Strength

|

>700 Mpa

|

|

Quality Standard

|

YB/T151-2017, CECS38:2004, JGJ/T221-2010, JT/T524-2004, JTG/T F30-2014, JGT3064-2014

|

|

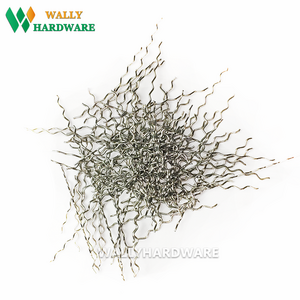

Shape

|

The Surface Polishing Blue Anti Rust Treatment, Cross Section Is Triangular, Surface Rough, Smooth Surface, Radial Distortion,

Both Ends of the Anchor Tail hook |

|

Color

|

Polishing Blue

|

|

MOQ

|

1 Kilogram

|

|

Packing

|

Paper Carton

|

Product Description

End Hook Chopped Milling Steel Fibers for Concrete Daye Price Hydraulic Engineering Steel Fiber Concrete

Pictures:

End Hook Chopped Milling Steel Fibers for Concrete Daye Price Hydraulic Engineering Steel Fiber Concrete

Features:

Mill-cut Steel Fiber

is the agent product of DAYE, which is developed & manufactured by Shanghai Harex Steel Fiber Technology Co., Ltd., the production raw materials are high-quality manganese alloy high-strength cast steel. Due to its special shape and advanced production technology. It has a special shape and high tensile strength, and has a significant strengthening effect on concrete (compared with ordinary mixed spring soil, the compressive strength is increased by 5-20%; the flexural tensile strength is increased by 20-50%; the compressive strength is increased by 20-40%; the wear resistance is increased by about 40%; under impact load, the crack resistance is increased by 3-4 times; the flexural tensile fatigue strength is increased by 1.65-2.25 times)

.

Packing:

e.g.

20kg/carton, 1200kg/pallet

.

Characteristics

:

1. Low dosage (minimum dosage: 0.25%, general dosage: 0.3-0.8%)

2. No agglomeration, no outburst, no rush, easy construction.

3. The cross section and longitudinal section of the steel fiber milled by the ingot have serrated edges, and there are anchor tails at both ends, so that the bond strength between the steel fiber and the mortar is doubled

.

Main

Functions

:

Adding an appropriate amount of steel fiber into the concrete can increase the tensile strength by 20% - 50% and the flexural strength by 40% - 80%. Under the normal fiber content, the impact compressive toughness can be increased by 2-7 times, and the impact shear and tensile toughness can be increased by several times to dozens of times. Due to the good crack resistance and integrity of steel fiber reinforced concrete, the freeze-thaw resistance, heat resistance, wear resistance, cavitation resistance and corrosion resistance of steel fiber reinforced concrete are significantly improved. Concrete collective itself is a heterogeneous, multi-component and heterogeneous granular brittle composite material. Its compressive ratio is only about one tenth, and its crack resistance is very low. The addition of steel fiber prevents the initiation of cracks and reduces the size and number of crack sources; In the process of stress, the extension and expansion of cracks are restrained, and the stress and concentration of cracks are alleviated

.

Construction

Proposals

:

Mill-cut Steel Fiber can be applied to a variety of construction methods without additional equipment. It can be directly stirred in the field, pumped and sprayed, fiber will not be carried forward, the surface is not exposed. Maintenance and ordinary concrete requirements are the same, especially suitable for large areas of paving, can greatly shorten the construction cycle

.

Main

Applications

:

1. Road Construction

2. Pavement layer of Bridge deck

3. Crack and seepage resistance of underground engineering concrete

4. Hydraulic Engineering

Standards:

1. YB/T151-2017

2. CECS38:2004

3. JGJ/T221-2010

4. JT/T524-2004

5. JTG/T F30-2014

6. JGT3064-2014

End Hook Chopped Milling Steel Fibers for Concrete Daye Price Hydraulic Engineering Steel Fiber Concrete.

End Hook Chopped Milling Steel Fibers for Concrete Daye Price Hydraulic Engineering Steel Fiber Concrete.

End Hook Chopped Milling Steel Fibers for Concrete Daye Price Hydraulic Engineering Steel Fiber Concrete

Hot Searches